Three-dimensional printing formation unit and method

A molding equipment and three-dimensional printing technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of complex parts production and low material utilization rate, and achieve simple parts production, high material utilization rate, post-production Handle simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

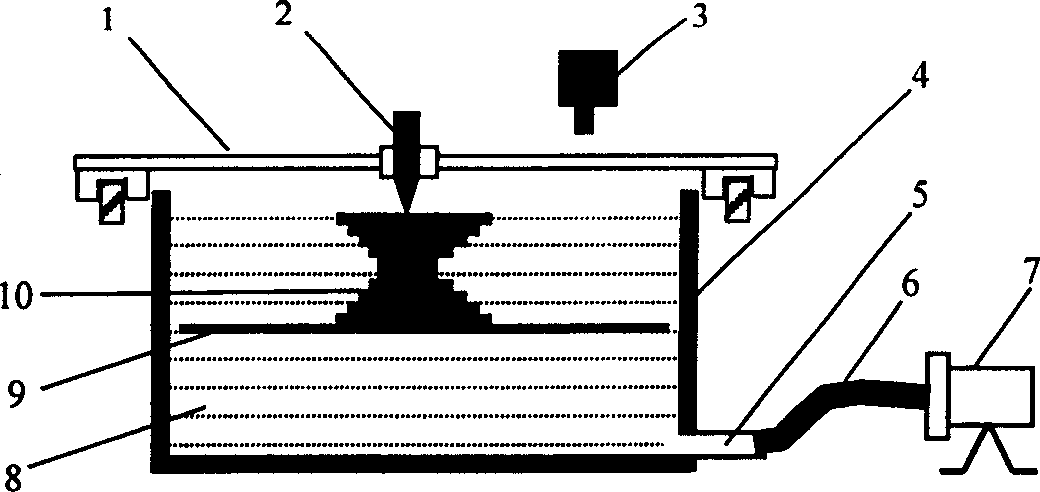

Embodiment 1

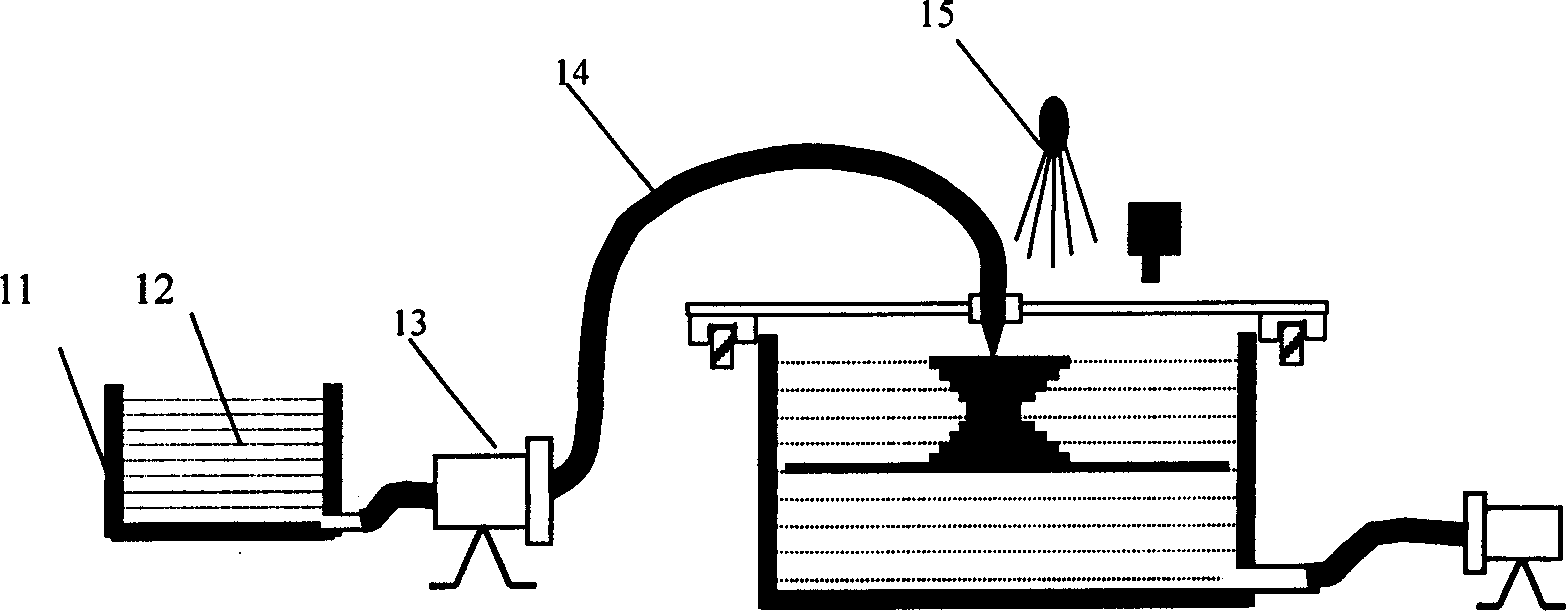

[0042] This embodiment adopts as figure 2 In the shown device of the present invention, liquid photosensitive resin 12 is selected as the molding material, and liquid epoxy resin is used as the support material 8 . The photosensitive resin storage 12 is stored in the raw material tank 11, and the photosensitive resin 12 is transported to the nozzle 2 through the conduit 14 and the pump 13. The photosensitive resin 12 ejected from the nozzle 2 is irradiated by the ultraviolet lamp 15, and the liquid photosensitive resin 12 is cured.

[0043] The processing process is as follows:

[0044] 1. The 3D CAD model data is processed by computer and divided into a series of cross-sectional graphics with a certain thickness.

[0045] 2. The lifting platform 9 is lifted to a certain height, and the liquid level sensor is used to detect the height of the liquid level 3. According to the detected liquid level height, the support material epoxy in the liquid storage tank 4 is changed throu...

Embodiment 2

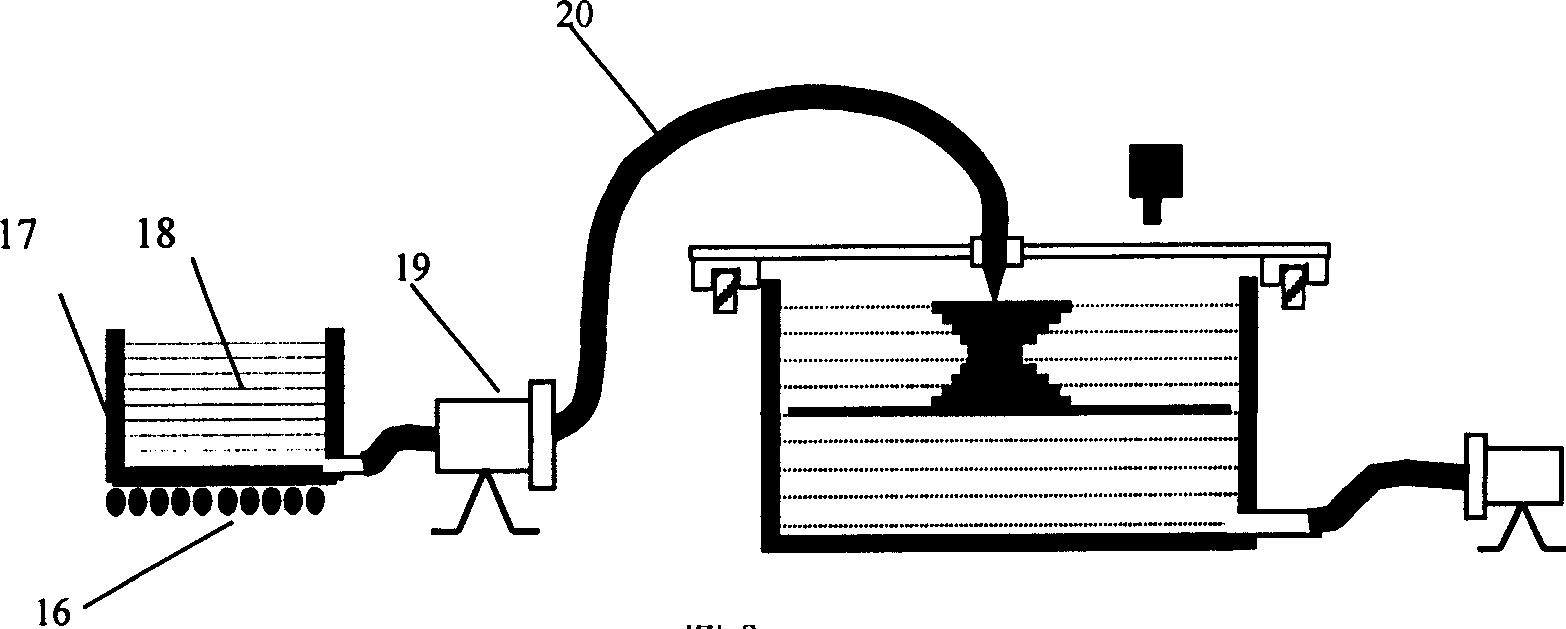

[0054] This embodiment adopts as image 3 In the shown device of the present invention, wax 18 is selected as the molding material, and liquid epoxy resin is used as the support material 8 . The wax 18 is stored in the raw material tank 17, heated to a molten state by the heating plate 16, and the molten wax is transported to the nozzle through the conduit 20 and the pump 19, and the molten wax ejected from the nozzle is cooled and solidified.

[0055] The processing process is as follows:

[0056] 1. The 3D CAD model data is processed by computer and divided into a series of cross-sectional graphics with a certain thickness.

[0057] 2. The heating plate 16 heats the raw material tank 17 to melt the solid wax and keep it at a stable temperature of 70-100°C.

[0058] 3. The lifting platform 9 is lifted to a certain height, and the liquid level sensor is used to detect the height of the liquid level 3. According to the detected liquid level height, the support material epoxy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com