Vision contraposition device for mobile component

A technology of visual alignment and moving parts, applied in the direction of electrical components, electrical components, etc., can solve problems such as the need to stop or strictly control, measurement and installation cannot be carried out at the same time, and reduce positioning accuracy, etc., to achieve a simple and fast alignment process of parts installation, Effects of cost reduction and structural complexity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

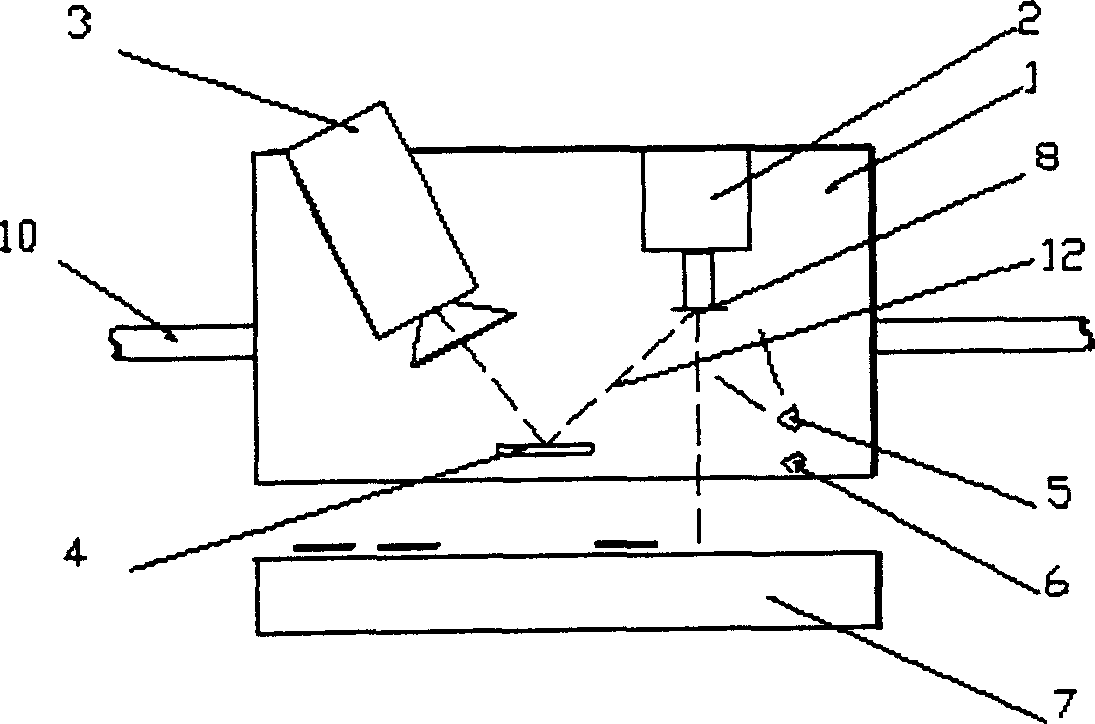

[0019] figure 1It is a structural schematic diagram of the present invention, a pick-up head 2, an electronic camera 3, a half-mirror 4, a reflective imaging light source 5 acting on the bottom of the component 8 and a transmission imaging light source acting on the installation position 9 are fixed on the pick-up mechanism platform 1 6. The pick-up mechanism platform 1 can move along the X-Y plane on the plane of the work platform 7, and only the X-axis guide rail 10 is shown in the figure; the pick-up head 2 faces the work platform 7 and can move along the Z-axis direction perpendicular to the X-Y plane of the work platform 7 . The visual system adopts visible light imaging, and the electronic camera 3 can adopt an industrial CCD or COMS camera, and the exposure can be controlled through an optical lens or a camera. / 2. The position of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com