Method for separating acetonitrile-methylbenzene azeotropic mixture by continuous extractive distillation

A technology of azeotrope and extractive distillation, applied in the direction of extractive distillation, etc., can solve problems such as no data yet, and achieve the effect of facilitating automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

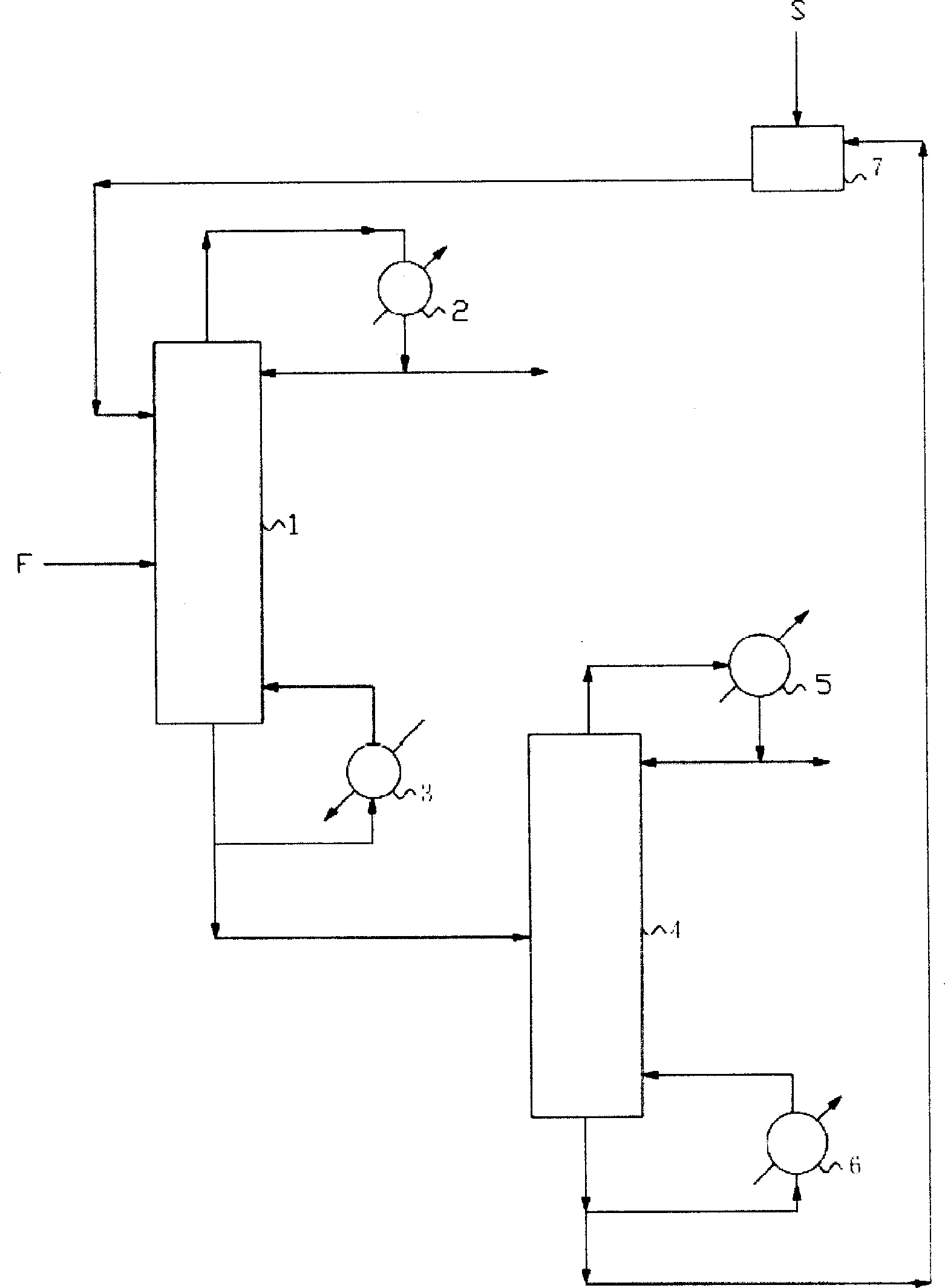

Image

Examples

Embodiment 1

[0011] The diameter of the extractive distillation tower used is φ80mm, and DIXON packing is installed inside. The total height of the packing layer is 1.2m, of which 0.2m from the top of the tower is the extraction agent inlet, and 0.5m from the bottom of the tower is the raw material inlet. The extraction agent recovery tower has a diameter of φ80mm and is equipped with DIXON packing. The total height of the packing layer is 0.8m, and the feed port is in the middle of the tower. The raw material is an acetonitrile-toluene mixture (wherein containing 73% of acetonitrile, 27% of toluene, both in mass percent) is added in the tower by the raw material inlet of the extractive distillation tower at a flow rate of 1Kg / h, and the extractant 1,4-diethylbenzene From the extractant high-level tank, it is fed into the extractive distillation tower from the extractant inlet, the feed temperature of the extractant is 70°C, and the flow rate is 3Kg / h. At the top of the extractive distillat...

Embodiment 2

[0013] The device that adopts is the same as embodiment one. Acetonitrile-toluene mixture (wherein containing acetonitrile 73%, toluene 27%, is mass percent) is added in the tower by the raw material inlet of extractive rectification tower with the flow rate of 1Kg / h, and extractant propylbenzene is from extractant head tank by extractant The inlet is added to the extractive distillation tower, the feed temperature of the extractant is 40°C, and the flow rate is 4Kg / h. At the top of the extractive distillation tower, after the material vapor is condensed by the extractive distillation condenser, part of it is refluxed, and part of it is recovered as acetonitrile product. out, the reflux ratio is 3:1, the temperature is 81.5°C, and the purity of the extracted acetonitrile is 99.2%. At the bottom of the extractive distillation tower, the material partly enters the reboiler to be vaporized, and partly extracted, the output flow rate is 4.27Kg / h, the extracted material enters the...

Embodiment 3

[0015] N-butylbenzene was used as the extractant, and the operation method and device were the same as in Example 1. The purity of the obtained acetonitrile was 99.4%, and the purity of toluene was 99.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com