Combustion pressure detecting apparatus

A technology of combustion pressure and detection device, applied in the direction of measurement device, measurement of rapid changes, instruments, etc., can solve the problems of being easily affected by heat, unable to accurately detect combustion pressure, etc., and achieve the effect of improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

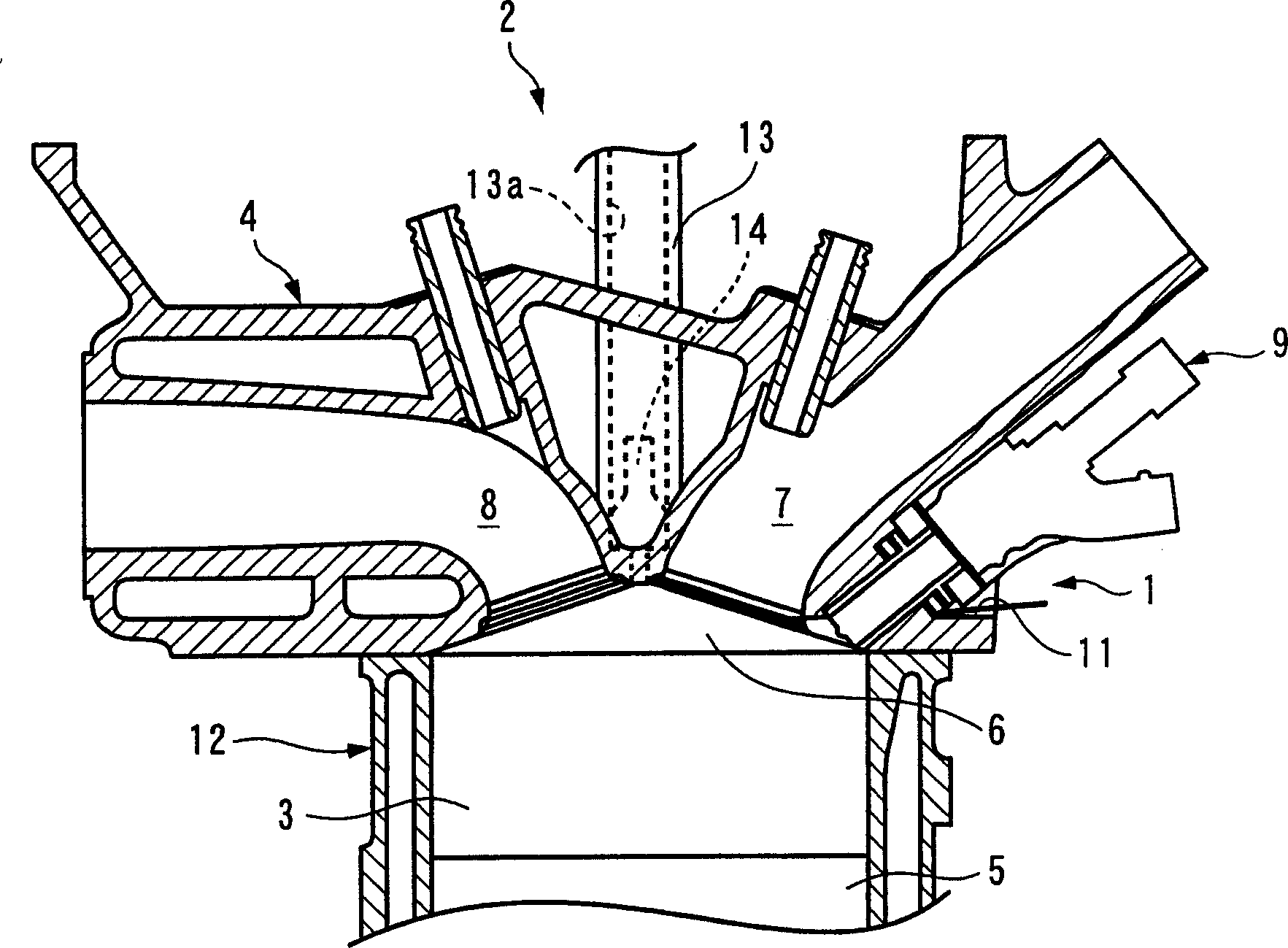

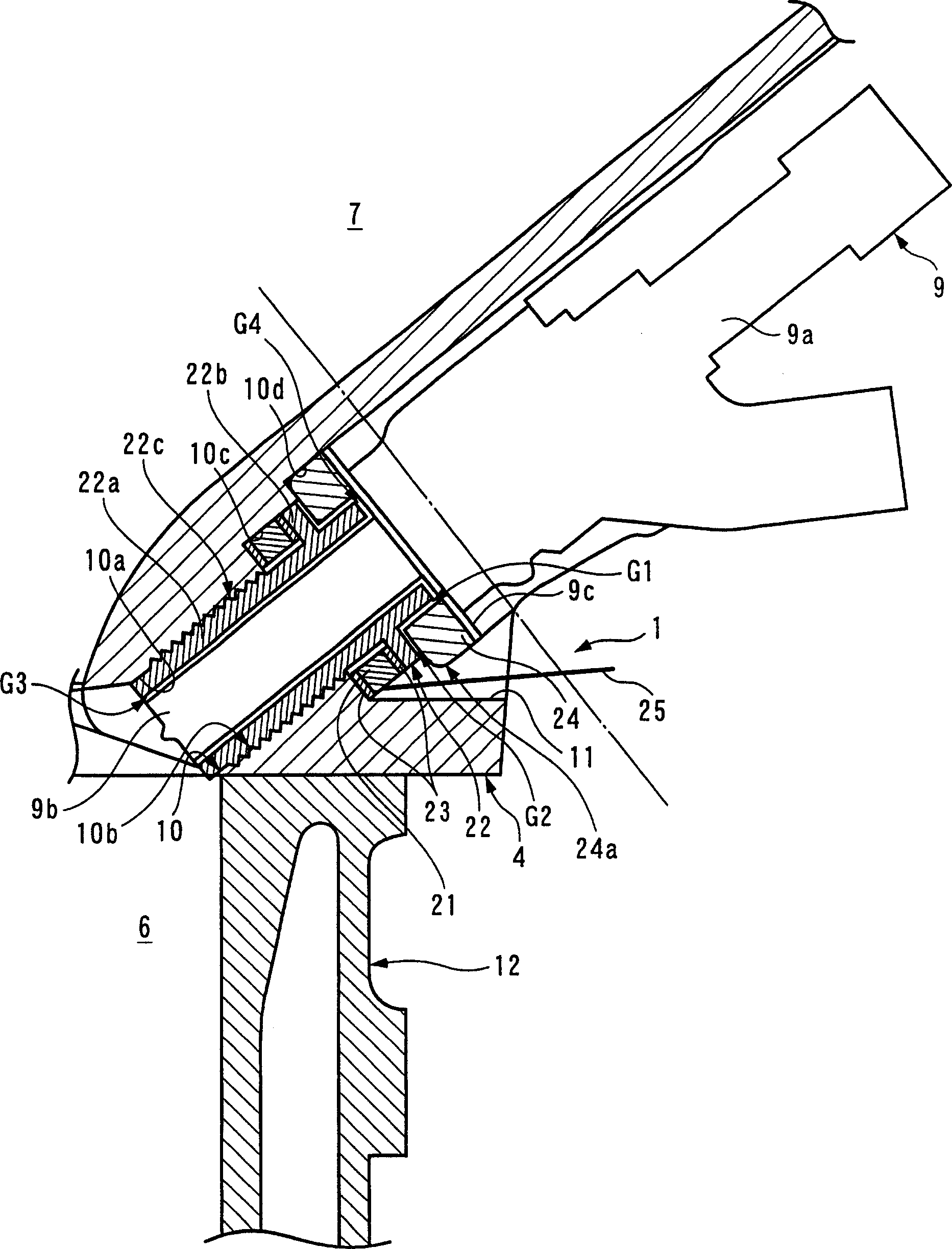

[0034] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. figure 1 A combustion pressure detecting device 1 and an internal combustion engine (hereinafter referred to as "engine") 2 provided with the device 1 according to the first embodiment of the present invention are shown. The engine 2 is, for example, an inline four-cylinder direct injection engine mounted on a vehicle (not shown), and has a cylinder head 4 and a cylinder block 12 . Four cylinders 3 (only one is shown) are arranged in parallel on the cylinder block 12, and the cylinder head 4 is mounted on the top of the cylinder block 12, and the two cylinders 4, 12 are firmly joined to each other. A combustion chamber 6 is formed between the cylinder head 4 and the piston 5 in each cylinder 3 .

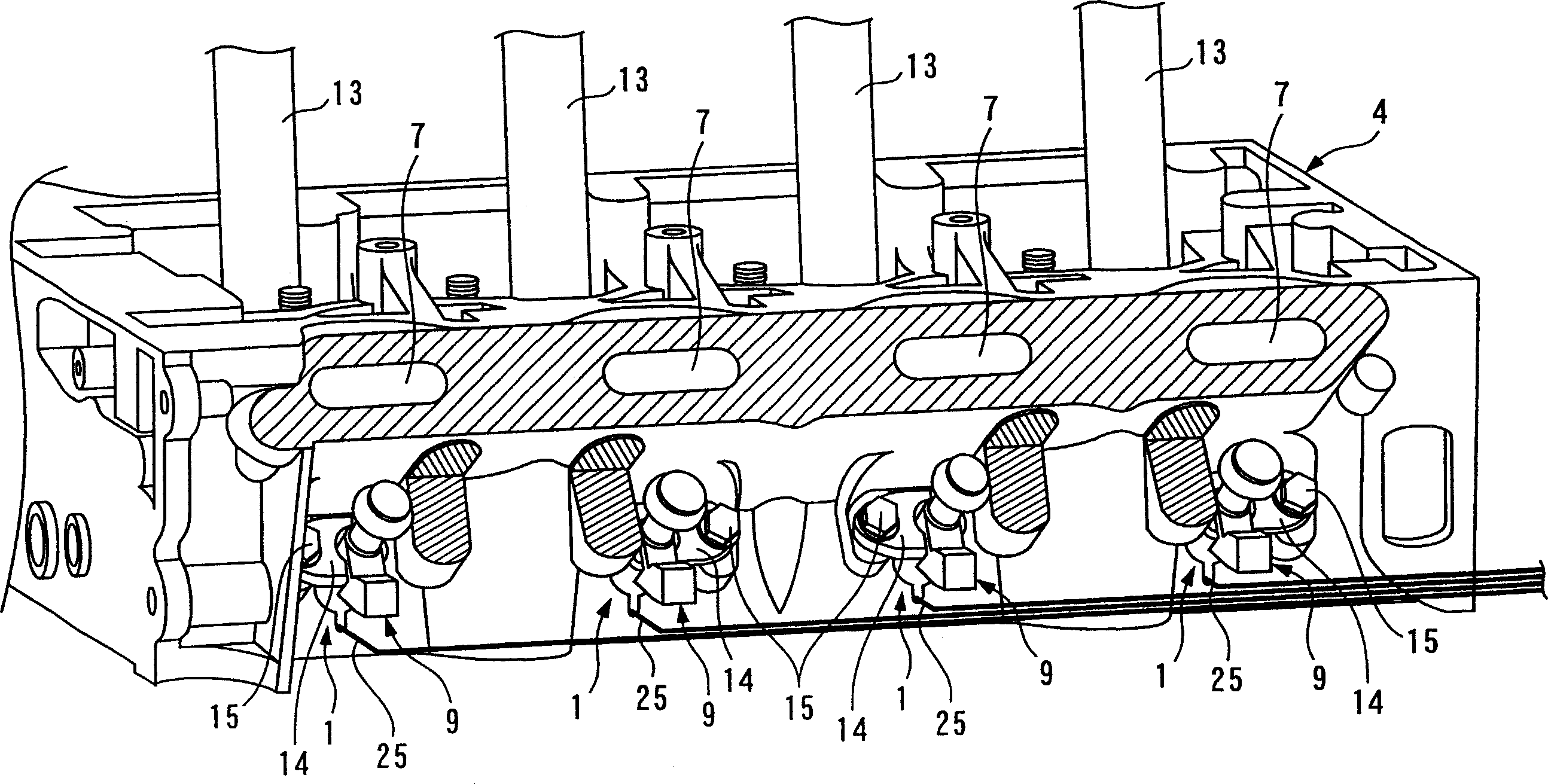

[0035] The cylinder head 4 is made of aluminum alloy, for example, and has figure 2 As shown in the complex shape, various constituent parts are installed. On the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com