Gasoline engine with two horizontally and oppositely arranged cylinders

A horizontally opposed gasoline engine technology, applied in the gasoline engine field, can solve the problems of large vibration, large volume, and increased production cost of gasoline engines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

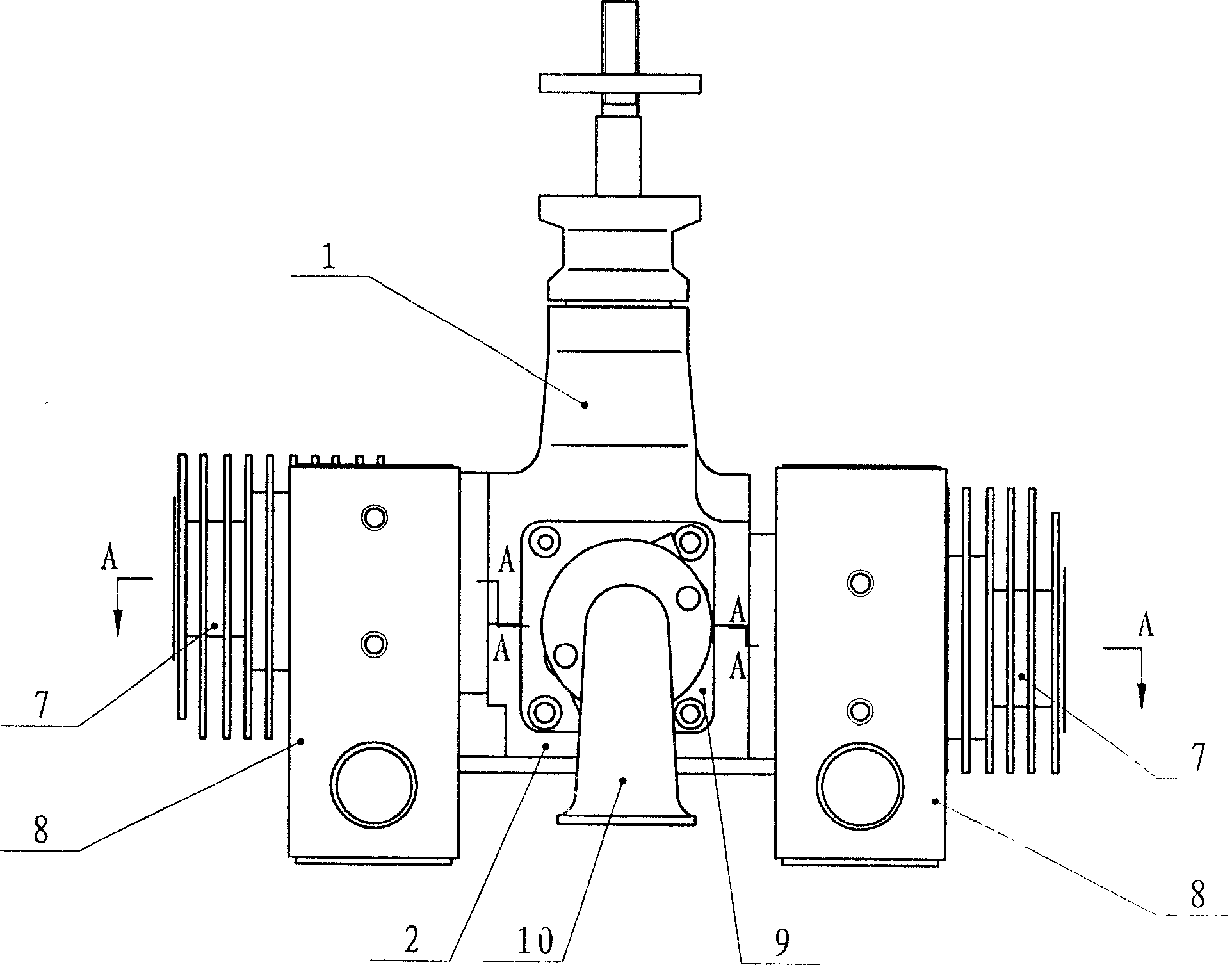

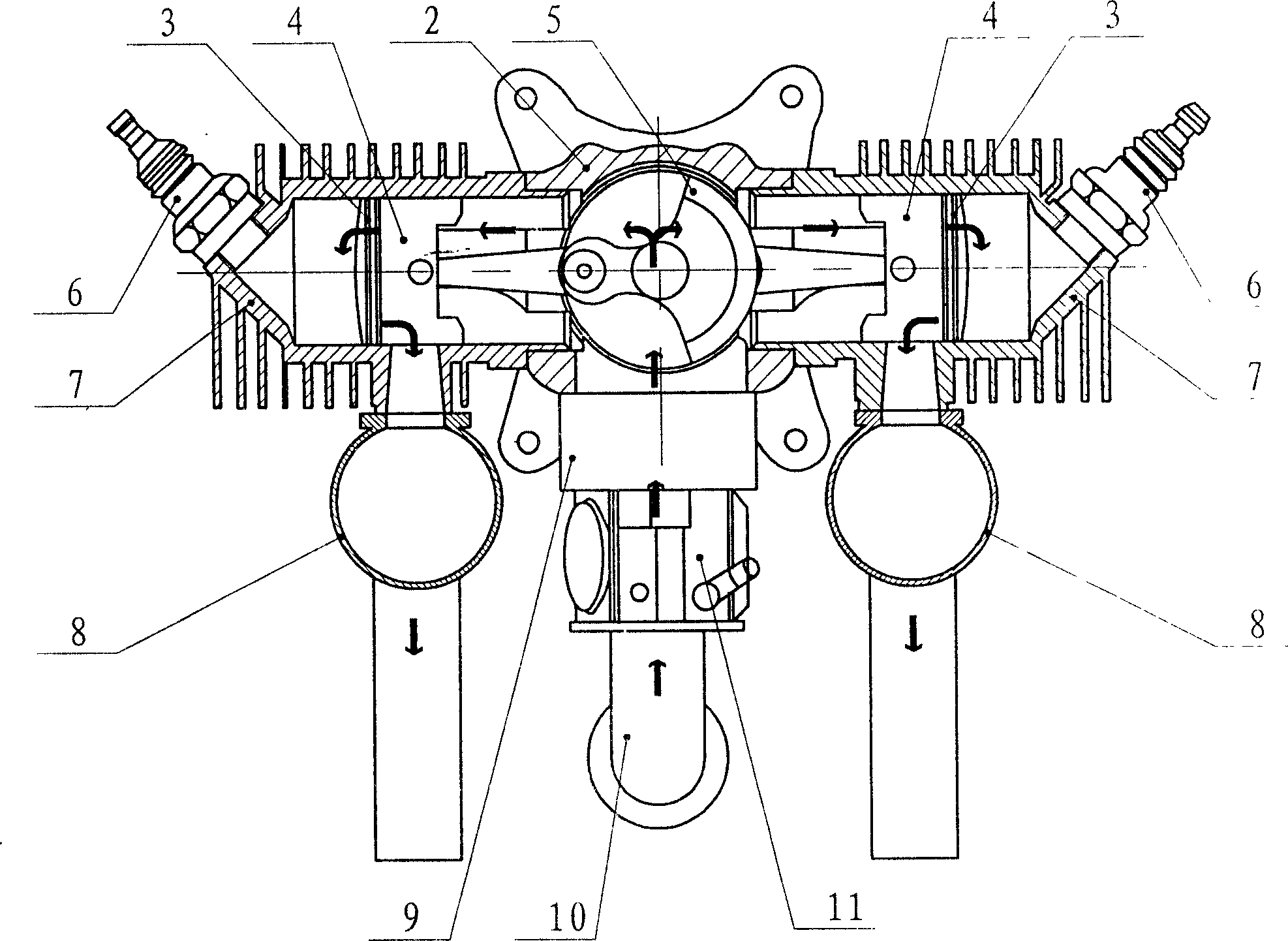

[0009] figure 1 and figure 2 Shown is a specific embodiment of a horizontally opposed twin-cylinder gasoline engine of the present invention, which includes upper and lower bodies 1, 2, cylinder block 7, spark plug 6, piston assembly 4, piston ring 3, crankshaft connecting rod assembly 5. Reed valve assembly 9, carburetor 11, the crankshaft connecting rod assembly 5 is arranged in the crankcase composed of the upper and lower body 1, 2, and the left and right cylinder blocks 7 are horizontally arranged in the upper and lower On both sides of the crankcase composed of the body 1 and 2, the piston assembly 4 is connected to one end of the connecting rod of the crankshaft connecting rod assembly 5 and arranged in the left and right cylinder blocks 7, and the left and right cylinder blocks 7 are respectively equipped with exhaust valves. Pipe 8 and carburetor 11 are fixedly connected on another plane of the crankcase formed by upper and lower body 1, 2 through reed valve assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com