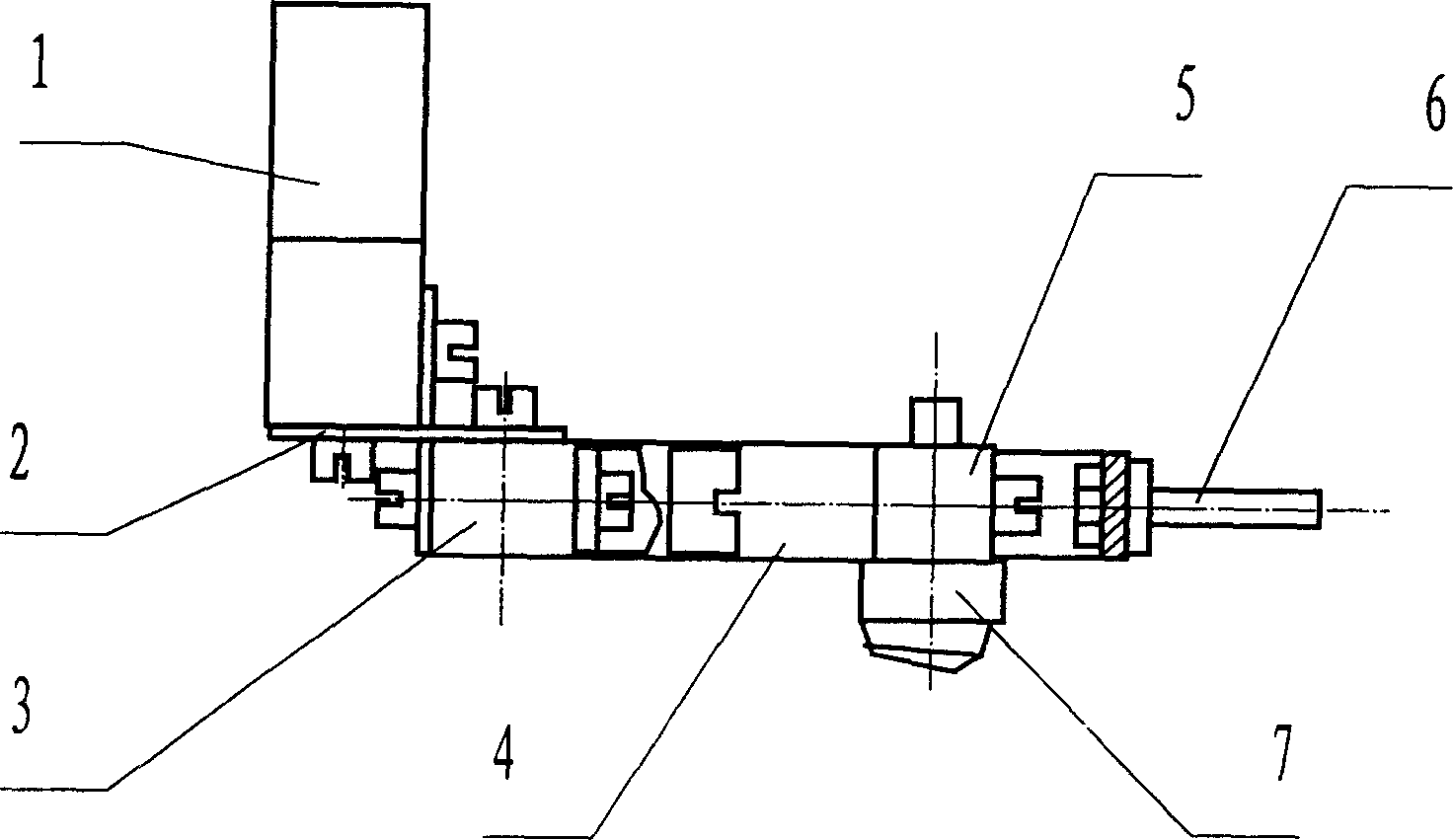

Multifunctional knife rest of optical grating notching knife in elastic withstanding pin type

A grating scribing knife, thimble-type technology, applied in diffraction grating, metal processing and other directions, can solve the problems of reduced diffraction efficiency of grating, difficult adjustment, unsuitable tool holder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

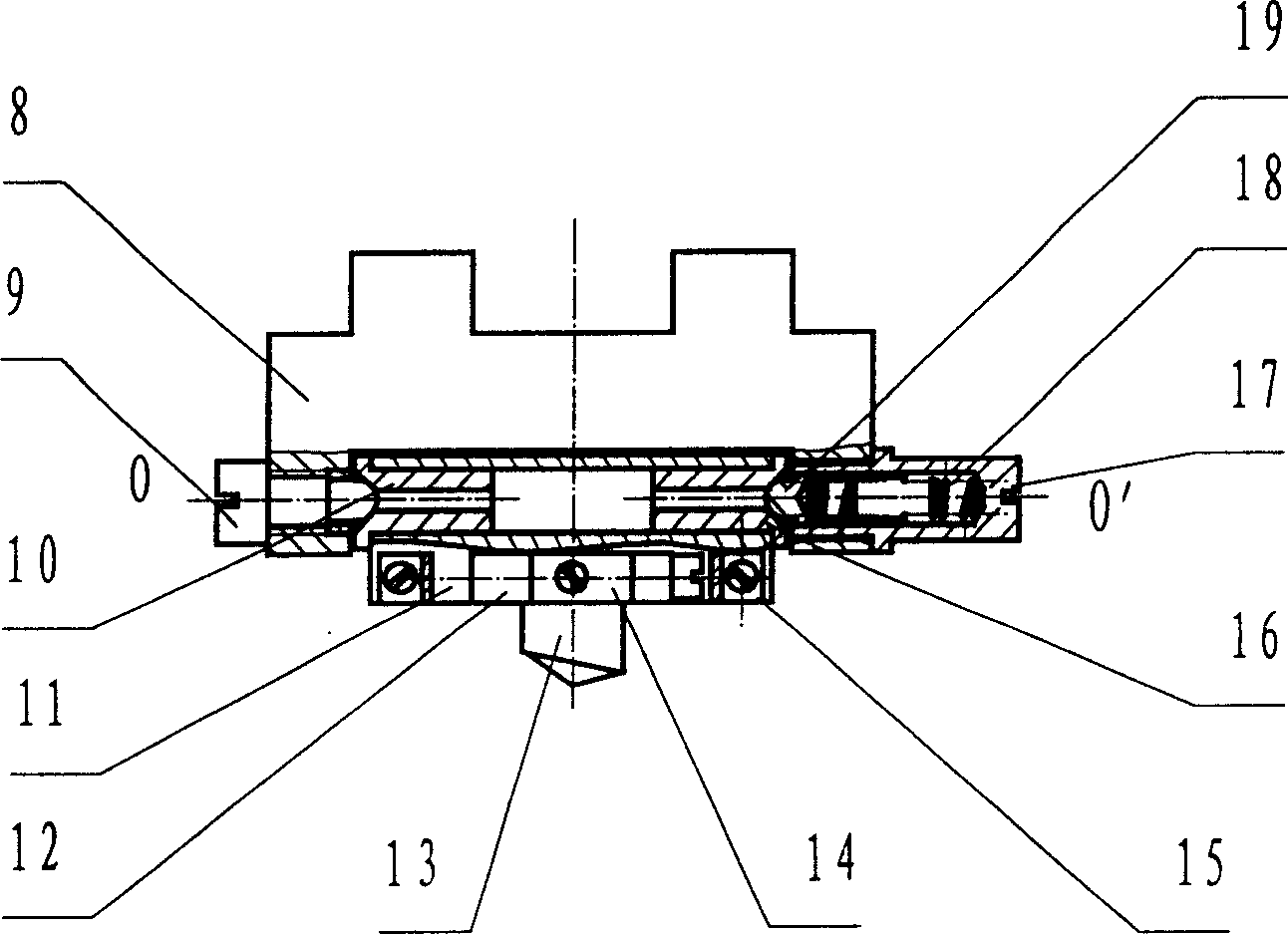

[0011] The invention according to image 3 with Figure 4 The structure shown is implemented, wherein the main tool rest 8, spherical thimbles 9 and 19, auxiliary tool rest 11, block 14, fixed sleeve 17, are all made of 45# steel, and the V-shaped shaft sleeves 10 and 16 are fastened. The material of weight block 20 all adopts brass, the material of lifting tool holder 15 adopts duralumin, and engraving knife 13 adopts diamond; The top of the auxiliary tool rest 11 is in a circular shape near the main tool rest 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com