Preparation method of industrial defoaming agent

A kind of defoamer, industrial technology, applied in the field of preparation of industrial defoamer, can solve the problems of complex production process, poor use effect, inconvenient use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

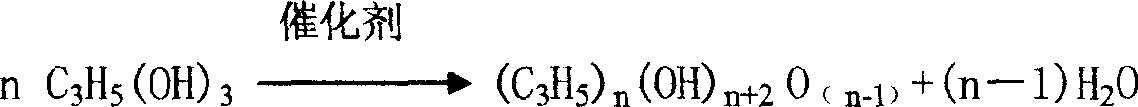

[0027] Take a 250ml three-necked flask, install a stirring, heating device, and a water separator, weigh 138g (1.5mol) of glycerin and add it to the three-necked flask, stir and heat up to 100°C, add 1.5g of catalyst, heat up to 230°C, and react for two hours , to obtain about 115g of slightly yellow polyglycerol product.

Embodiment 2

[0029] Take the reaction device as an example 1. Weigh 184g (2mol) of glycerol, stir and heat up to about 100°C, add 4g of catalyst, continue to heat up to 230°C, and react for four hours to obtain about 150g of light yellow polyglycerol product.

Embodiment 3

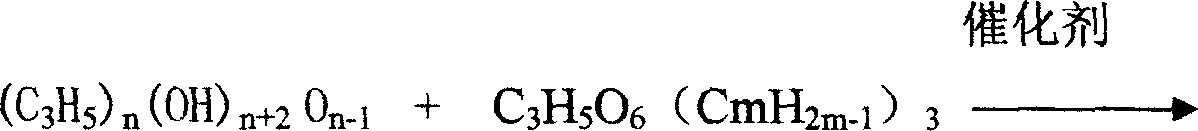

[0031] Get a 250ml three-neck flask, install a stirring and heating device, get 120g of the polyglycerol product obtained in Example 1, heat up to 120°C, add stearic acid 80g (0.25mol) and catalyzer 2g, heat up to 200°C and stir for three hours to obtain about 160g product, the appearance is a brownish black waxy solid, emulsified in hot water, the defoaming time is 28 seconds, and the foam suppression time is greater than 5 minutes (syrup for foaming liquid).

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com