Organic protective paint having low adding quantity of nano titanium particle and its preparation method

A technology of protective coatings and additions, applied in epoxy resin coatings, coatings, etc., to achieve the effect of low industrial application cost and low additions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

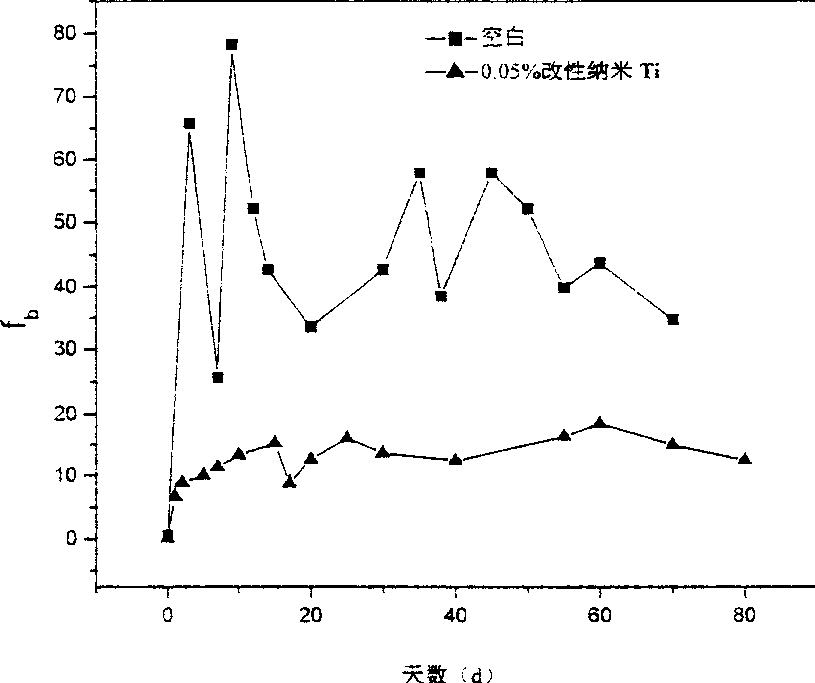

Embodiment 1

[0037] Coating Formulation:

[0038] Modified nano-Ti particles: 0.05% (with a particle size of 20-80nm);

[0039] Dispersant: 0.5%;

[0040] Dibutyl phthalate: 5%;

[0041] Xylene: n-butanol=7: 3 20%;

[0042] Epoxy resin (using E-44): balance.

[0043] Among them: nano-Ti particle composition and modification method:

[0044] Ingredients (percentage by weight):

[0045] al 2 (SO 4 ) 3 Solution (10%) 5%;

[0046] NaOH solution (10%) 5%;

[0047] Nano Ti particles 70%;

[0048] Deionized water 20%.

[0049] The preparation of the modified nanoparticles is to introduce hydroxyl groups (through Al 2 (SO 4 ) 3 react with NaOH); specific operation: put nano-Ti particles into a round-bottomed flask, slowly pour deionized water into it, stir, and at the same time raise the temperature to 60 °C, put the Al 2 (SO 4 ) 3 The solution and the NaOH solution were added dropwise at the same time, and the dropping rate was controlled at 30 drops / min; after the dropwise addit...

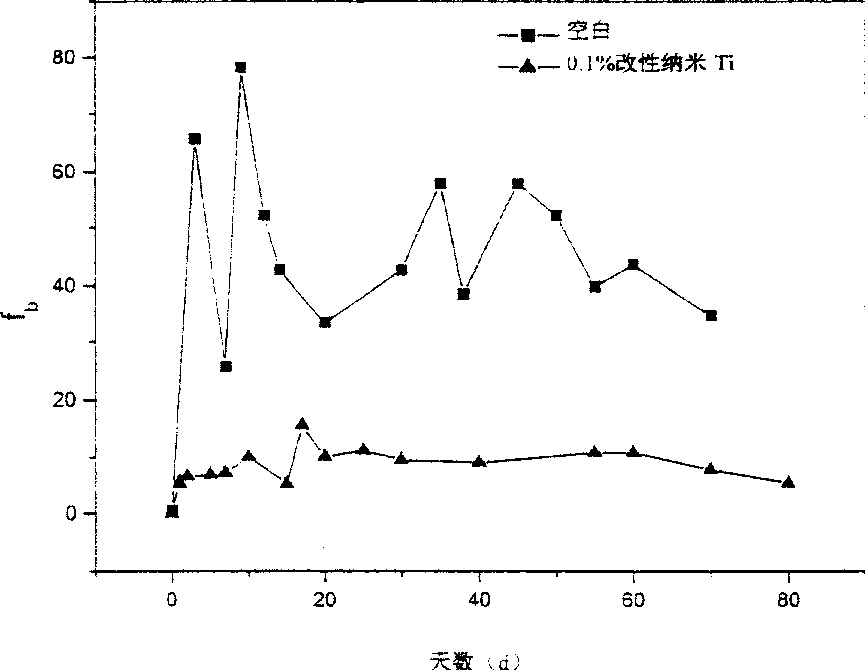

Embodiment 2

[0061] Difference with embodiment 1 is coating formula:

[0062] Modified nano-Ti particles: 0.1% (particle size 20-80nm);

[0063] Dispersant: 1%;

[0064] Dibutyl phthalate: 5%;

[0065] Xylene: n-butanol=7: 3 5%;

[0066] Epoxy resin (using 6458): balance.

[0067] Wherein: Nano Ti particle modification composition (by weight percentage):

[0068] Al 2 (SO 4 ) 3 Solution (10%) 20%;

[0069] NaOH solution (10%) 20%;

[0070] Nano Ti particles 50%;

[0071] Deionized water 10%.

[0072] The difference in the preparation of the modified nanoparticles is: put the nano-Ti particles into a round bottom flask, slowly pour deionized water into it, stir, and at the same time raise the temperature to 65°C, and put the Al 2 (SO 4 ) 3 The solution and the NaOH solution were added dropwise at the same time, and the dropping rate was controlled at 25 drops / min; after the dropwise addition was completed, the temperature was kept and continued to stir for 3 hours; after the re...

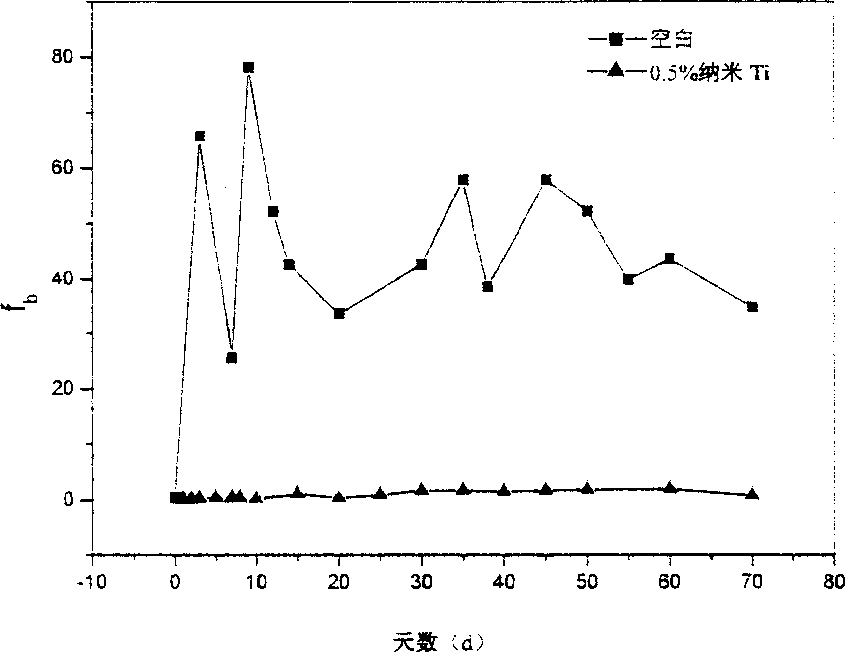

Embodiment 3

[0079] Embodiment 3 (by weight percentage)

[0080] Difference with embodiment 1 is coating formula:

[0081] Nano-Ti particles: 0.5% (particle size 55-100nm);

[0082] Dispersant: 1%;

[0083] Dibutyl phthalate: 5%;

[0084] Benzene: n-butanol=6:4 20%;

[0085] Epoxy (E-42): balance.

[0086] Wherein dispersant composition (by weight percentage):

[0087] Potassium dodecylbenzenesulfonate 50%;

[0088] Disperbyk-161 45%;

[0089] Benzene 5%.

[0090] Accurately weigh the prepared paint mother liquor, add polyamide curing agent in a ratio of 10:6, and after aging for 1 hour, smear and cure. Conduct coating protection performance tests (see image 3 ).

[0091] Depend on image 3 It can be seen that the characteristic frequency of the coating added with 0.5% nano-Ti particles has been kept in a small range, indicating that the protective performance of the coating is better than that of the coating without nano-Ti particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com