Manufacturing method of small aperture metal bend for pipe

A manufacturing method and small-caliber technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve problems such as large impact, unfavorable, vibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] see Figure 1 to Figure 9 , The manufacturing method of the small-diameter metal elbow of the present invention: its main process is: taking material, forging, finishing, splitting, pairing, welding, grinding, taking the elbow of the required angle, and cutting the weld.

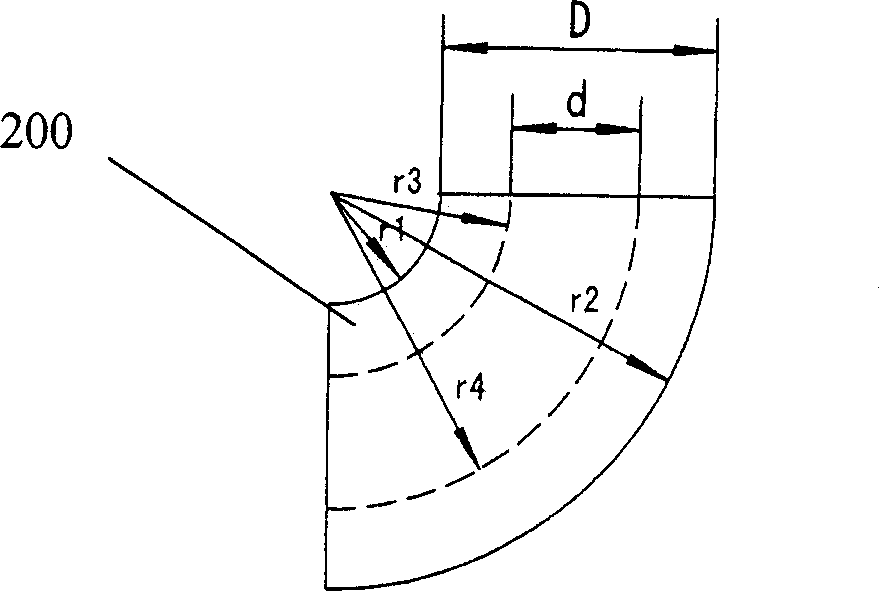

[0021] The details are as follows: Take the production of 180-degree elbow as an example, such as figure 1 , figure 2 As shown, first select a suitable material, and forge it into a blank 100 for metal cutting; press image 3 Turning is required for the size of the elbow 200 to be manufactured, where r1 is the radius of the inner arc of the elbow, r2 is the radius of the outer arc of the elbow, r3 is the radius of the inner arc of the inner hole of the elbow, and r4 is the outer arc of the inner hole of the elbow Radius, D is the outer diameter of the elbow, and d is the inner diameter of the elbow; the blank 100 is turned into a semicircular annular body, such as Figure 4 As shown, the radius of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com