Control method of mobile steel rail pneumatic welding machine and its used equipment

A control method and mobile technology, applied in welding equipment, welding equipment, arc welding equipment, etc., can solve the problems of large fluctuations in the pass rate of rail joint drop weight test, unstable welding joint quality, low degree of automation, etc. The process is stable and reliable, the effect of reducing human influence and improving the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

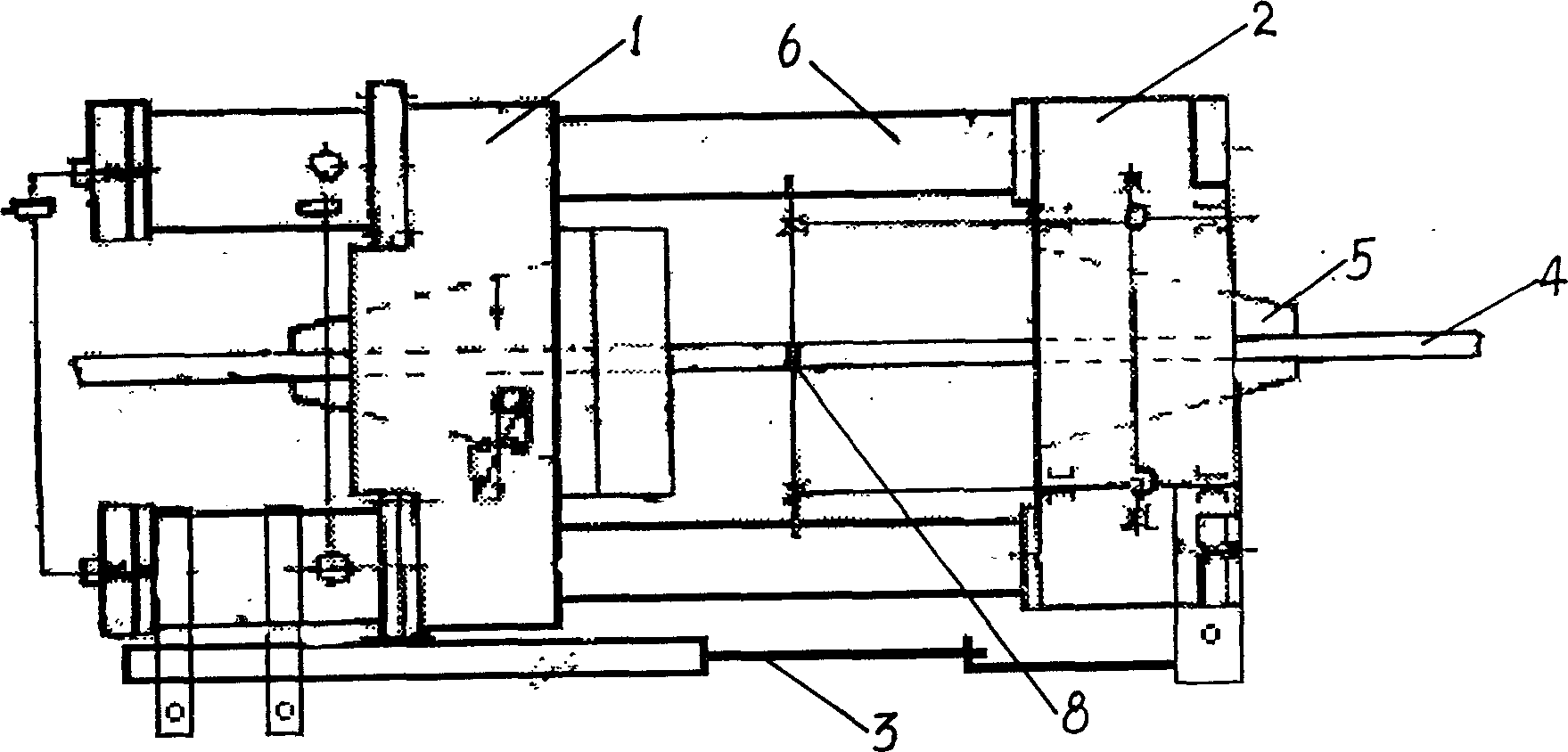

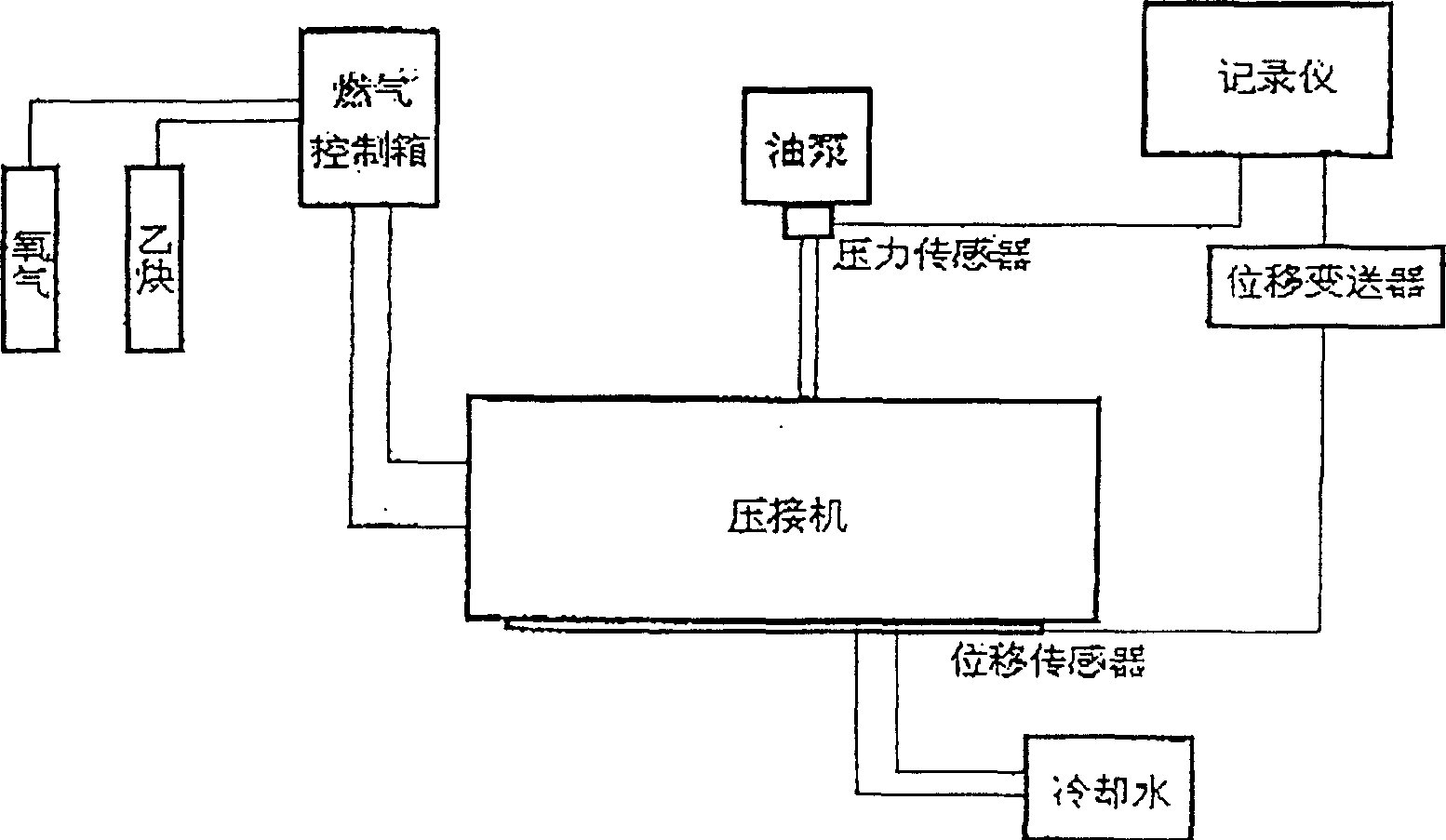

[0033] Put the two welded rails 4 that have been pretreated by end grinding and manual filing into the crimping machine, turn on the high-pressure oil pump, and adjust the weld position of the welded rails 4 and the distance between the left beam 1 and the right beam 2 of the crimping machine. distance to ensure that the tumor pushing device successfully removes the welding tumor. Tighten the rail waist slant iron 5 of the clamp waist crimping machine or tighten the compression bolts of the bottom clamping crimping machine, and tighten the rail top bolts to ensure the up and down and left and right straightness of the welded rail 4. Put in the pusher pad, close to the left beam 1 of the crimping machine, and prepare for pushing the pusher after welding. Turn on the instrument power supply, select the input signal range of the recorder, and pre-zero the recorder. Turn on the high-pressure oil pump, pre-fuel pressure to 26MPa, and adjust the initial zero position of the displac...

Embodiment 2

[0035]Put the two welded rails 4 that have been pretreated by end grinding and manual filing into the crimping machine, turn on the high-pressure oil pump, and adjust the position of the weld 8 of the welded rails 4 and the position between the left beam 1 and the right beam 2 of the crimping machine. The distance between them ensures that the tumor pushing device successfully removes the welding tumor. Tighten the rail waist slant iron of the clamp waist crimping machine or tighten the compression bolts of the bottom clamping crimping machine, and tighten the rail top bolts to ensure the up and down and left and right straightness of the welded rail 4. Put in the pusher pad, close to the left beam of the crimping machine, and prepare for the pusher after welding. Turn on the instrument power supply, select the input signal range of the recorder, and pre-zero the recorder. Turn on the high-pressure oil pump, pre-fuel pressure to 26MPa, and adjust the initial zero position of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com