Chip resistor and method of manufacturing the same

A chip resistor and resistive film technology, applied in the direction of resistors, trimming resistors, non-adjustable metal resistors, etc., can solve the problems of small change rate, long time, low retention rate, etc., and achieve weight increase and decrease, The effect of reducing manufacturing cost and reducing retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Embodiments of the present invention will be described below with reference to the drawings.

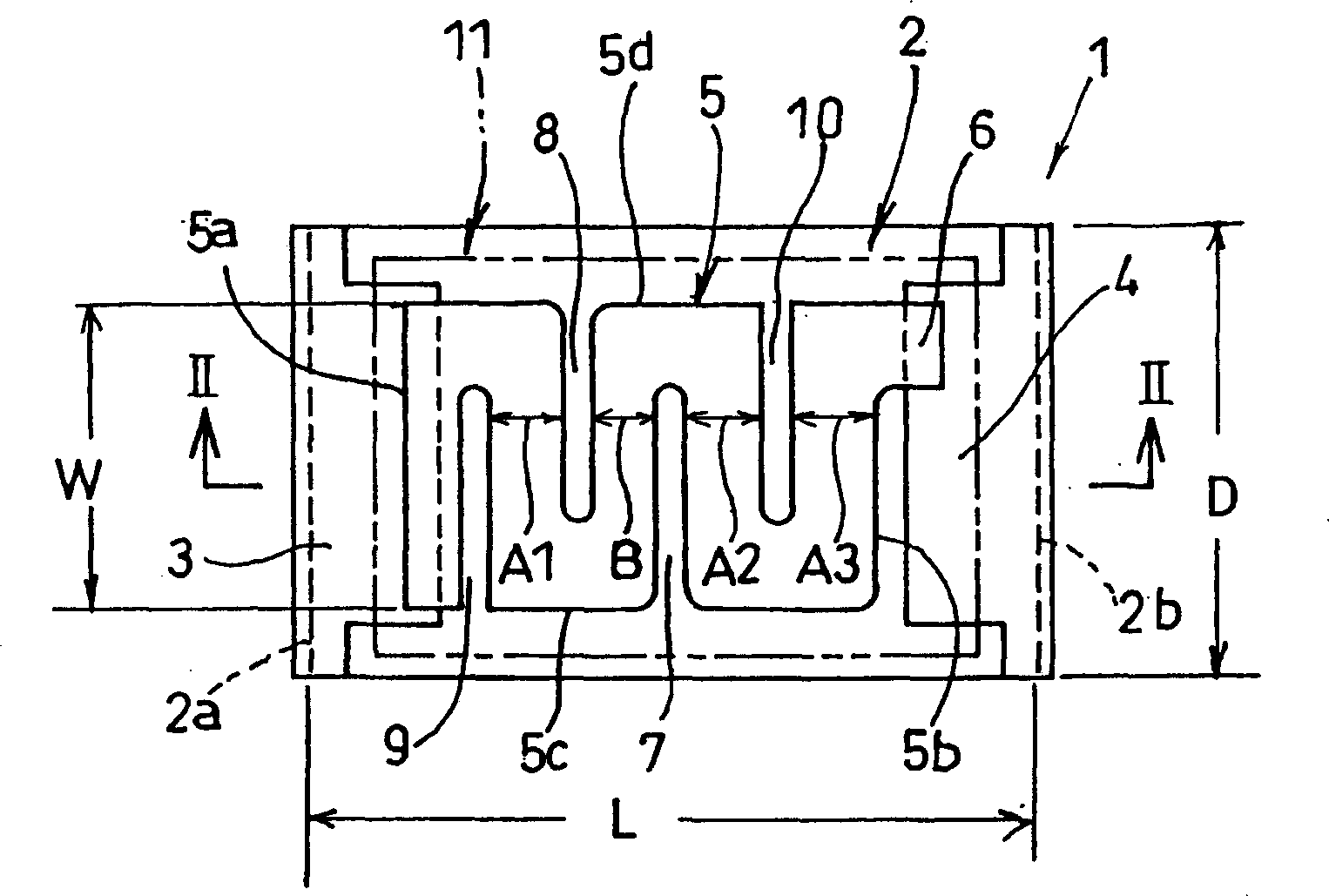

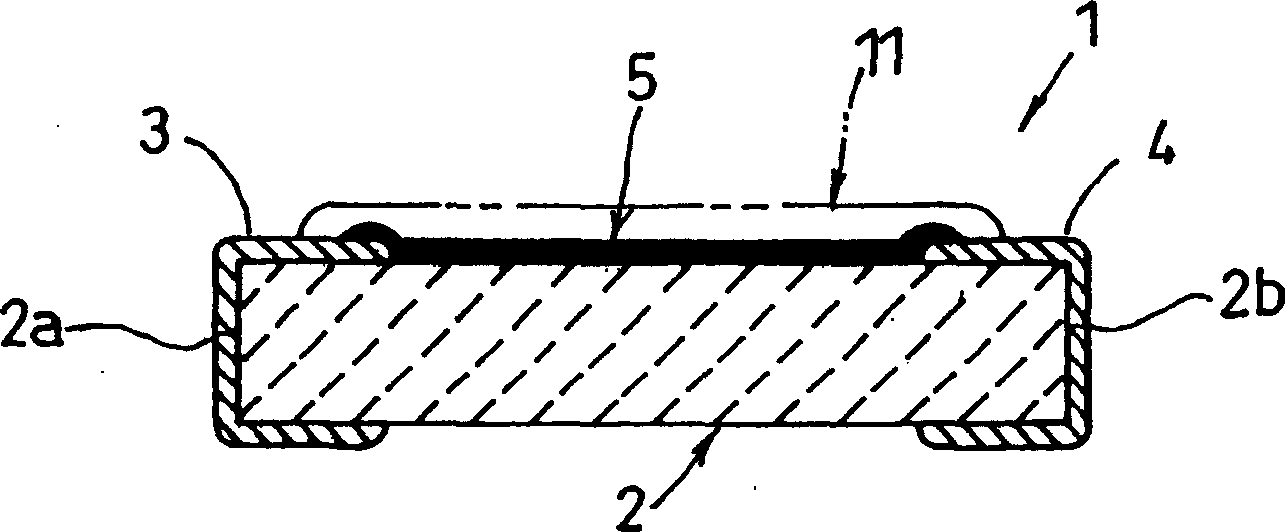

[0049] figure 1 and figure 2 The chip resistor 1 according to Embodiment 1 of the present invention is shown.

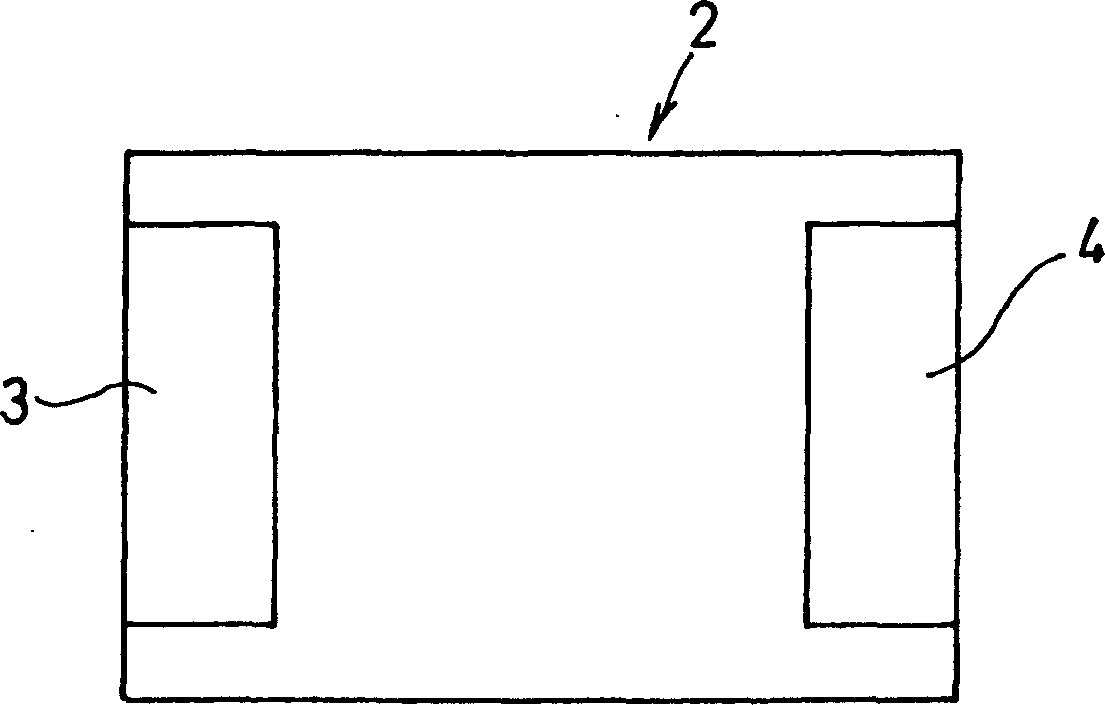

[0050] In the chip resistor 1, terminal electrodes 3 and 4 are formed on the left and right ends extending in the longitudinal direction on the upper surface of a rectangular chip-shaped insulating substrate 2 having a width D and a length L. On the one hand, on the part between the terminal electrodes 3 and 4 in the upper surface of the insulating substrate 2, the screen printing of its material paste and the subsequent calcination are used to form a suitable width dimension W along the The resistive film 5 extending in the longitudinal direction of the insulating substrate 2 .

[0051] When the resistive film 5 is formed by screen printing, one end 5a in the longitudinal direction of the resistive film 5 overlaps and connects to the one terminal electrode 3 with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com