Method for producing static discharging protection in micro module and relative microelectronic module

A technology of electrostatic discharge and microelectronics, applied in the direction of circuits, electrical components, electric solid devices, etc., can solve the problems of increasing the number of microelectronic module pads and increasing the demand for microelectronic module areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

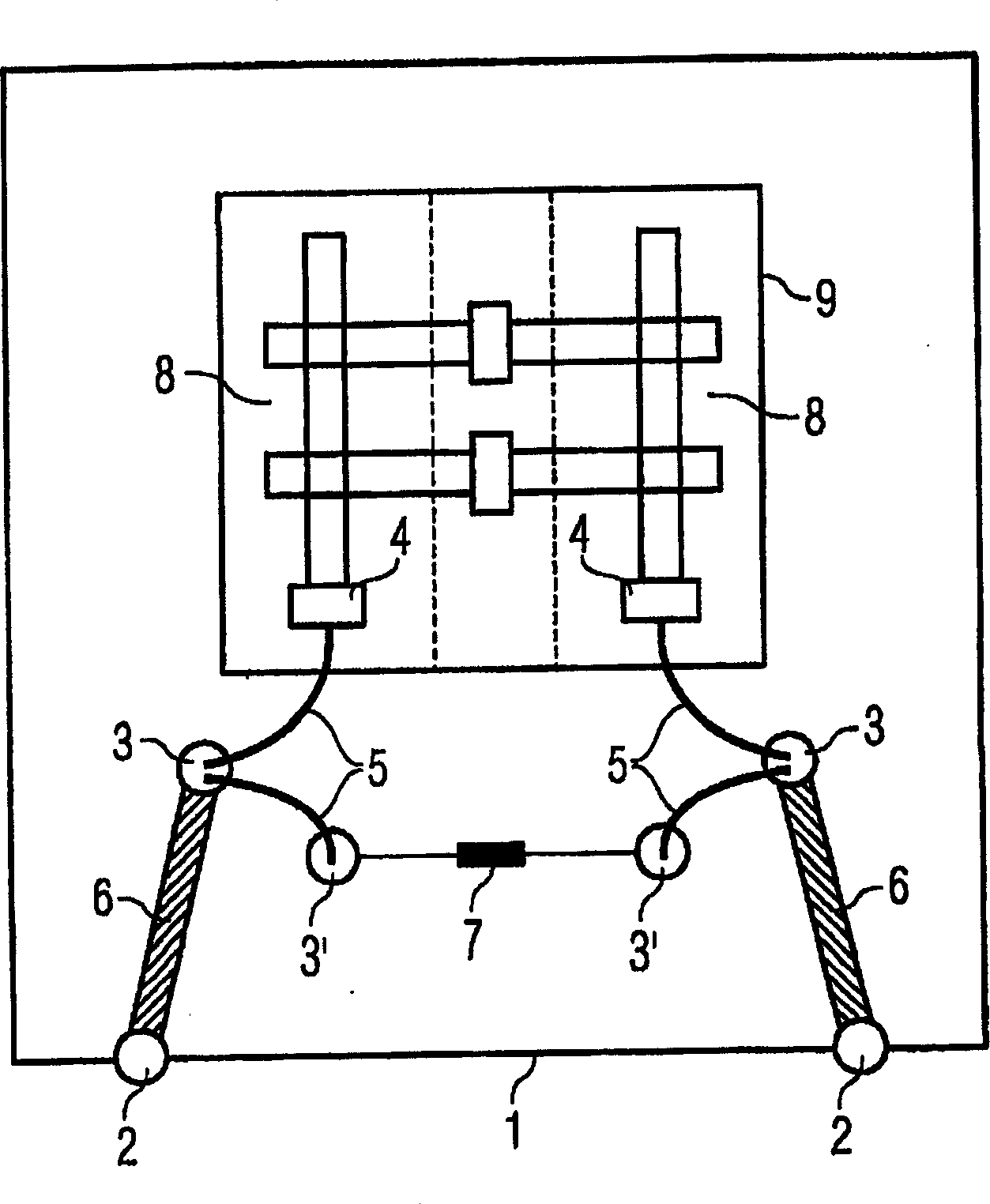

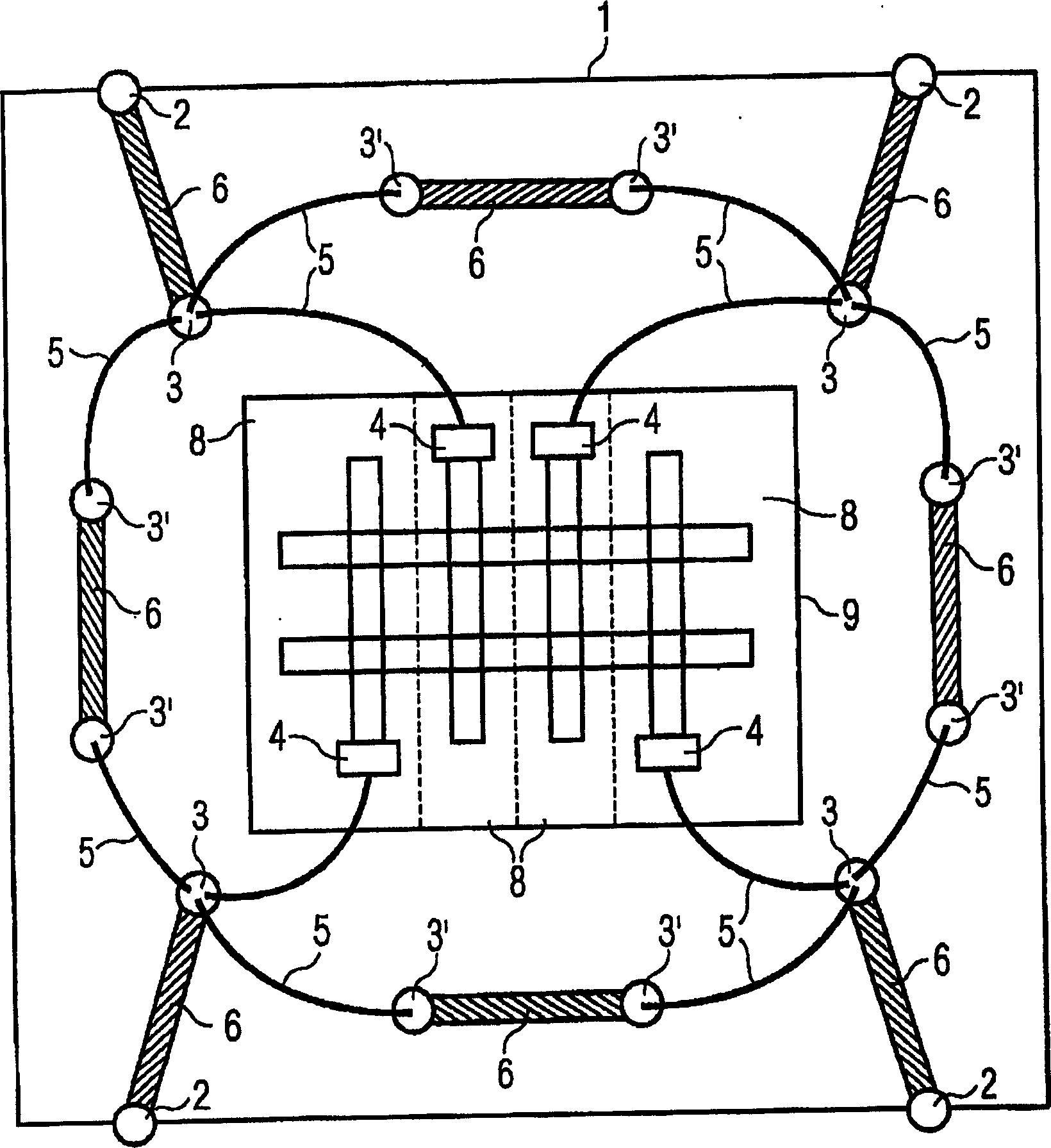

[0025] figure 1 Shown is a microelectronic module 1 comprising a semiconductor circuit 9 with two independent voltage supply domains 8 each having a voltage supply connection pad 4 connected via a connection line 5 to An internal terminal 3, (in another embodiment, the connection between the voltage supply connection pad 4 and the internal terminal 3 can also be realized only by a soldering point instead of the connecting line 5), each The internal terminal 3 is connected to an external terminal 2 of the microelectronic module 1 via an interconnection package 6 and to another internal terminal 3 ′ via a connecting line 5 . The two internal terminals 3' are connected to each other by means of an inducer 7, which can be achieved for example by coils, whereby a low-group resistive connection with a high inductance establishes a voltage supply connection between two independent voltage supply domains 8 between liner 4.

[0026] The ESD protection of the microelectronic module 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com