Desiccant refrigerant dehumidifier systems

A refrigeration system and drying technology, applied in refrigerators, heating and ventilation control systems, refrigeration components, etc., can solve the problem of expensive installation and achieve the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

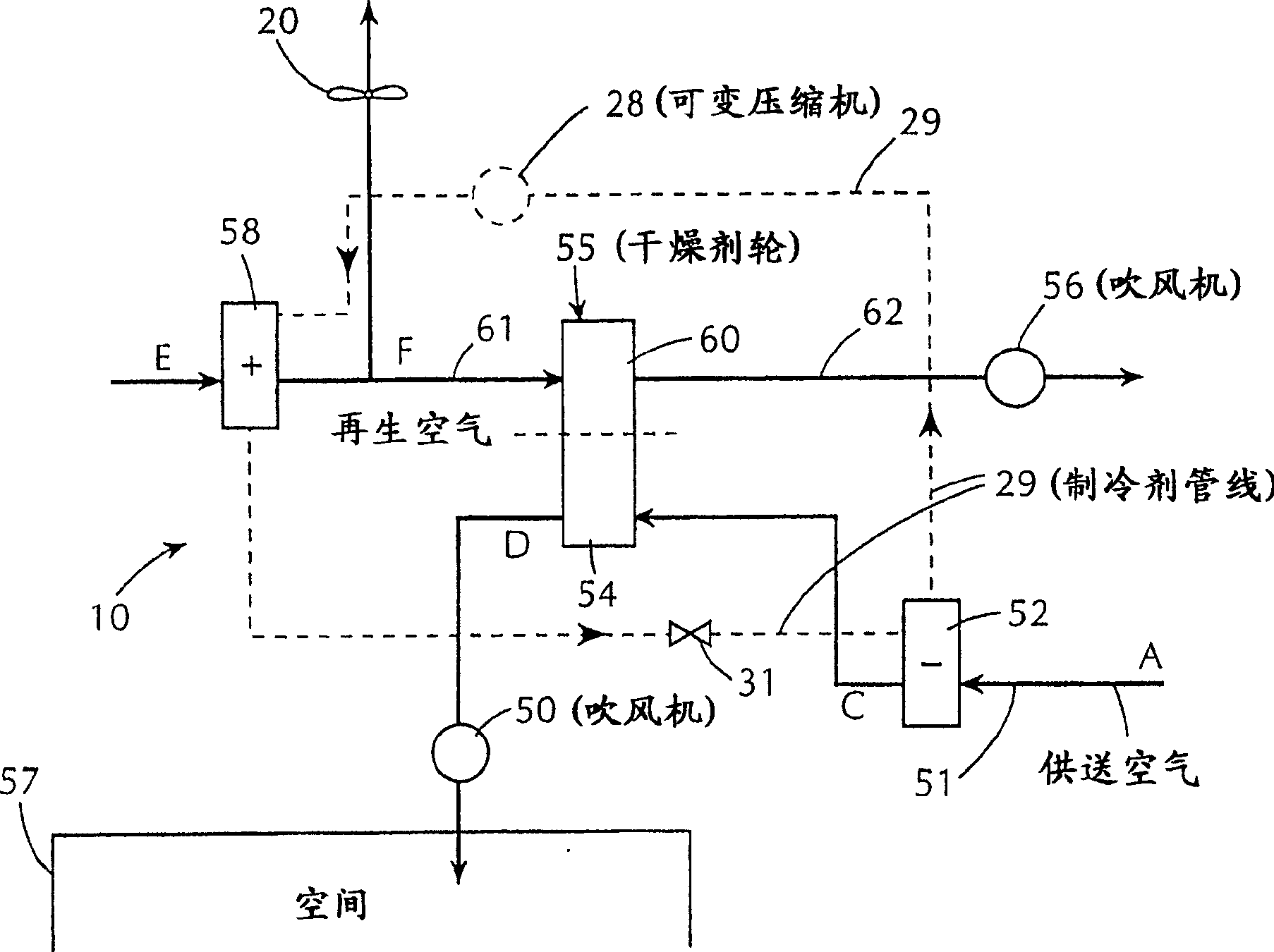

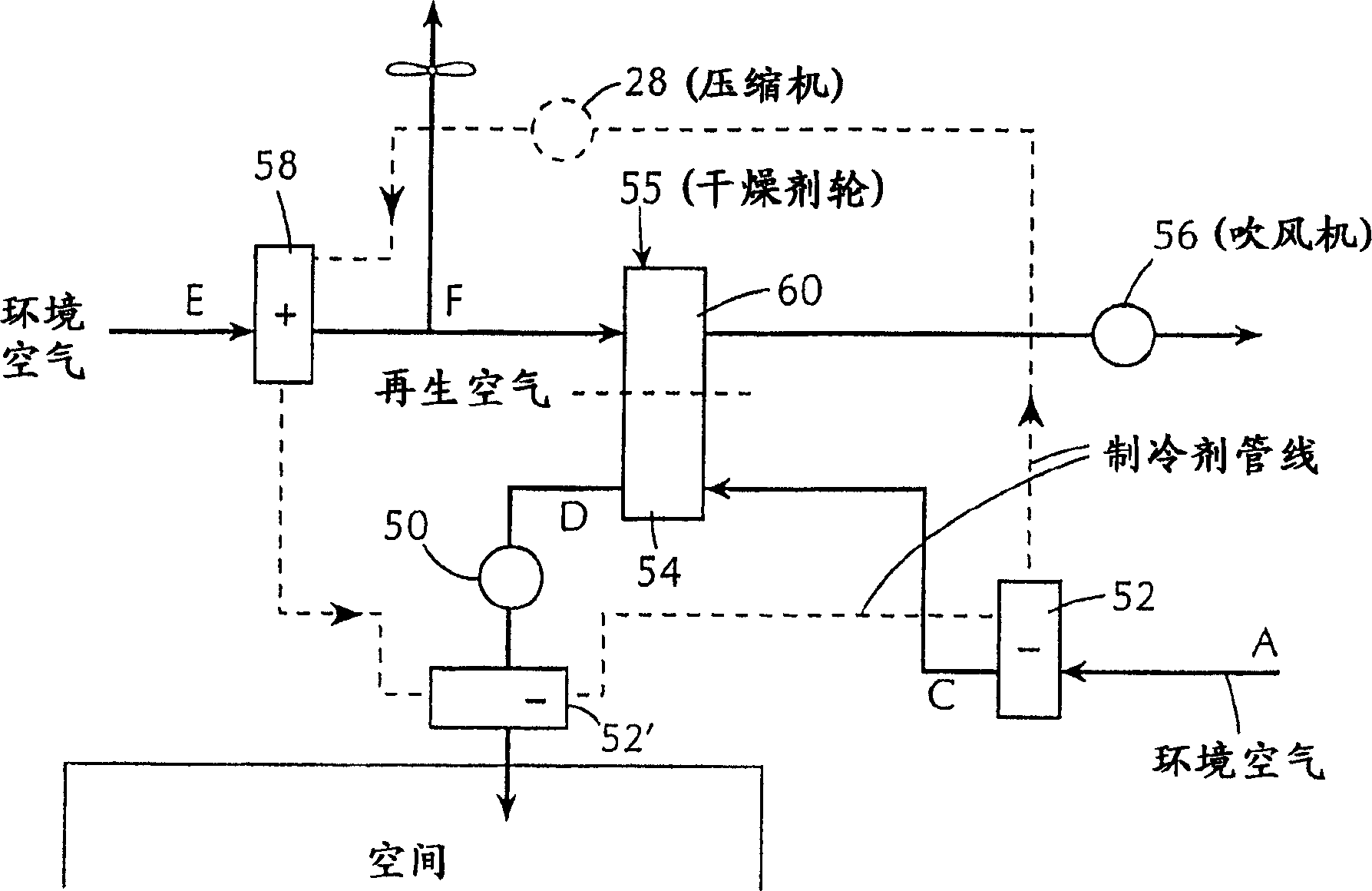

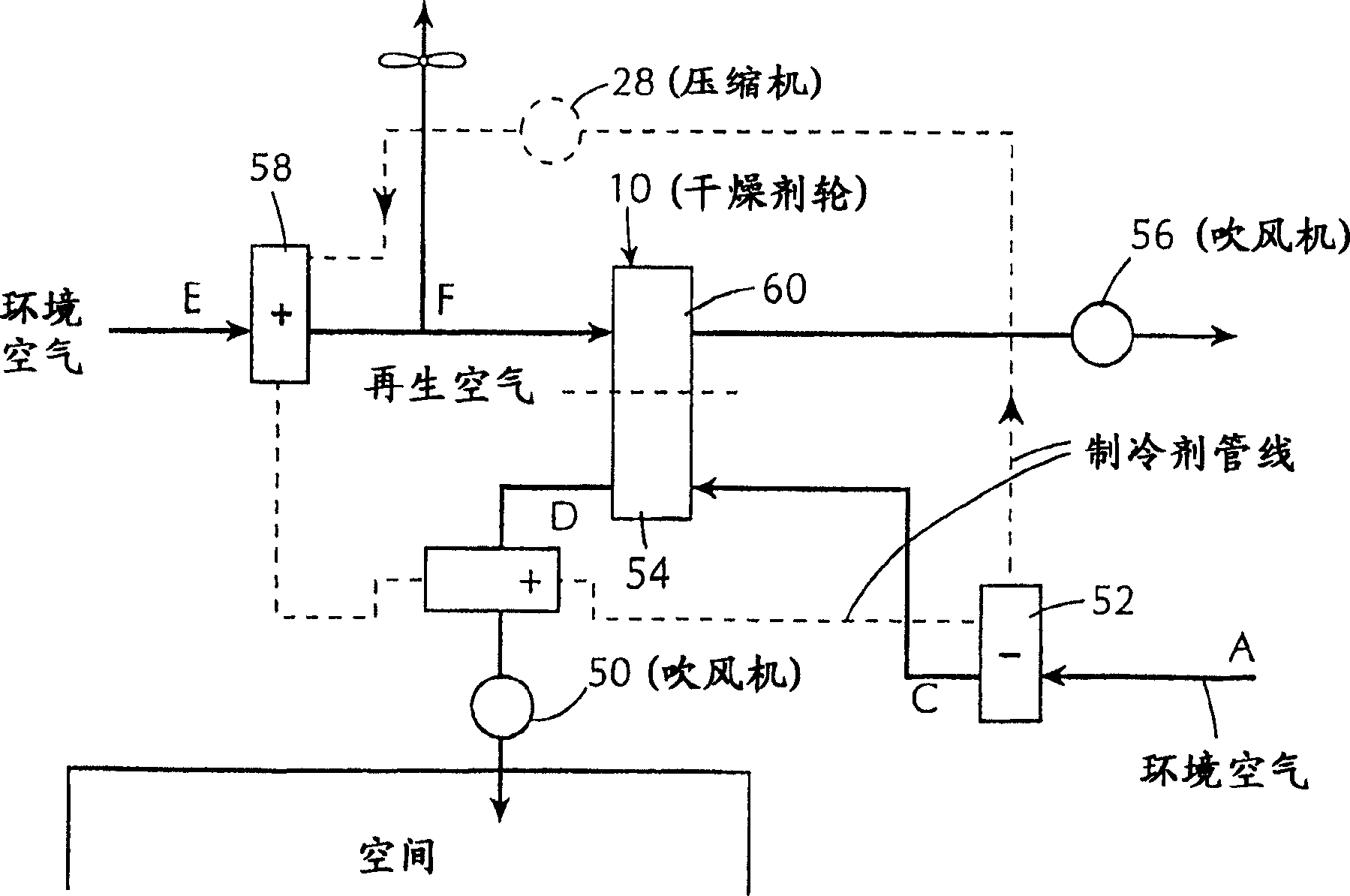

[0030] Referring now to the attached drawings in detail, see first figure 1, which shows a simplified air conditioning dehumidification system 10 according to the present invention, which uses a refrigerant cooling system and a rotating desiccant wheel dehumidification system. This system is a refinement of the system disclosed in our original application. In this case, the system takes air at any ambient state and processes it to virtually any drier, cooler humidity state with low enthalpy.

[0031] In system 10, the refrigerant cooling system comprises a refrigerant cooling circuit comprising at least one cooling or evaporator coil 52, at least one condenser for liquid / gas refrigerant carried in connecting refrigerant line 29 coil 58 and compressor 28 . In use, supply air from the atmosphere is drawn by blower 50 through ductwork 51 etc., through cooling coils 52 of the refrigeration system where it is cooled and slightly dehumidified. From there, the air passes through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com