Prefabricated dry-type capacity type cable terminal

A cable termination, capacitive technology, applied in cable accessories, cable installation, electrical components, etc., can solve the problems of poor bending resistance of cable terminations, difficult detection, inability to use transformer oil, etc. Reasonable electric field distribution and the effect of improving bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the embodiments according to the accompanying drawings.

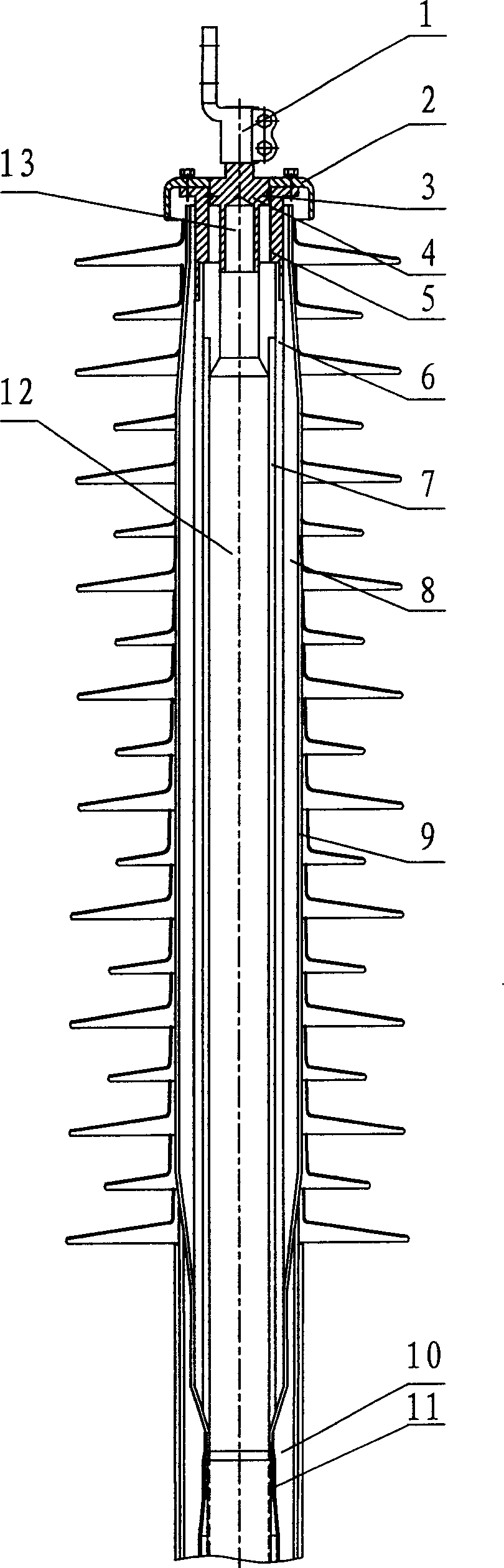

[0013] The synthetic rubber tube 7 is covered with a rigid insulating cylinder 6, and the rigid insulating cylinder 6 is covered with capacitive insulation 8 made of plastic insulating tape, the transition flange 5 is fixed on the rigid insulation cylinder 6, the pressure equalizing cover 2 and the transition flange 5 connection, the pressure equalizing cover 2 is installed on the conductive rod 4, the upper end seal 3 is placed between the conductive rod 4 and the transition flange 5, the terminal 1 is fixed on the conductive rod 4, and the innermost screen of the capacitive insulation 8 is connected to the voltage equalization The cover 2, the conductive rod 4, and the transition flange 5 are equipotentially connected, and the capacitive insulation 8 has an insulating sheath 9 outside. When in use, the conductive rod 4 and the cable core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com