Catalyst system for synthesis of diphenyl carbonate by ester exchange reaction

A technology of diphenyl carbonate and transesterification, which is applied in the direction of organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, carbonate/haloformate preparation, etc. Stability, low catalyst activity, corrosion equipment and other problems, to achieve good economic and social benefits, high activity, no corrosion equipment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

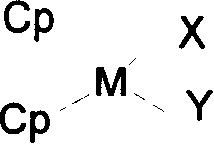

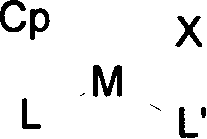

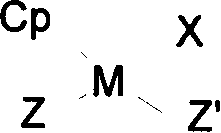

[0020] 1. Fix a 100ml three-neck round bottom flask on a heat-collecting constant temperature heating magnetic stirrer. The three-necked flask is equipped with a thermometer, a nitrogen conduit, a rectification column and an atmospheric pressure dropping funnel. Under normal pressure, replace the air in the reaction device with a nitrogen conduit, add 0.3mol phenol and 0.0015mol titanocene compound as a catalyst under nitrogen protection, stir and raise the temperature, and start to drop dimethyl carbonate when the temperature rises to 150°C. The total amount of dimethyl carbonate added was 0.3 mol. Keep the reaction temperature between 150°C and 180°C. At this time, the reaction system is in a boiling state, and at the same time, collect the azeotrope formed by the distilled methanol and dimethyl carbonate. The reaction time was 10 hours.

[0021] After the reaction, the catalyst was filtered off, and the solution was analyzed by gas chromatography. The conversion rate of ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com