Image sensor and method for fabricating the same

An image sensor and partial light technology, applied in solid image signal generators, image communication, image signal generators, etc., can solve the problems of high driving voltage, lack of color images, and high processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Preferred embodiments of the invention will now be described in detail, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

[0029] Hereinafter, an image sensor and a manufacturing method thereof according to the present invention are described as follows.

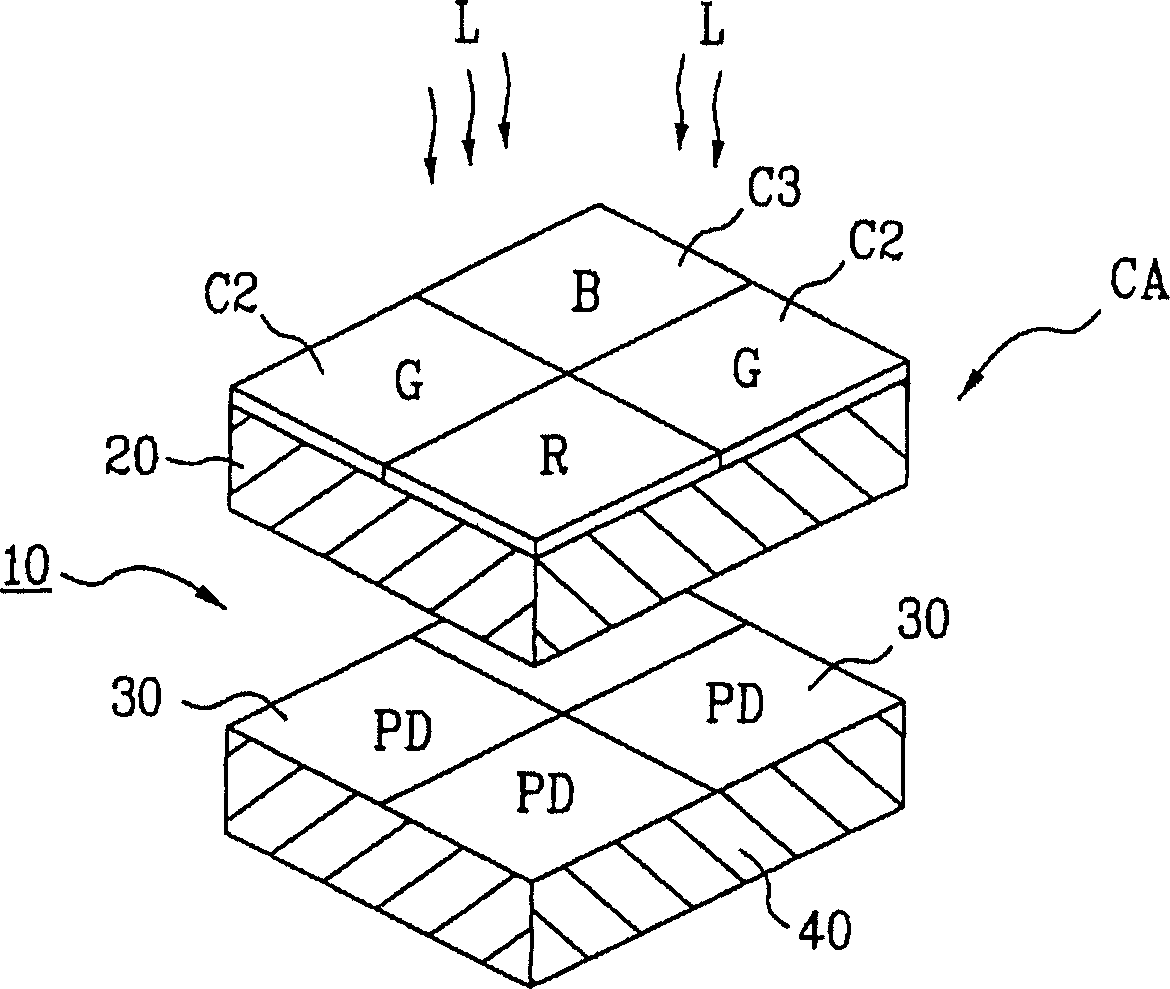

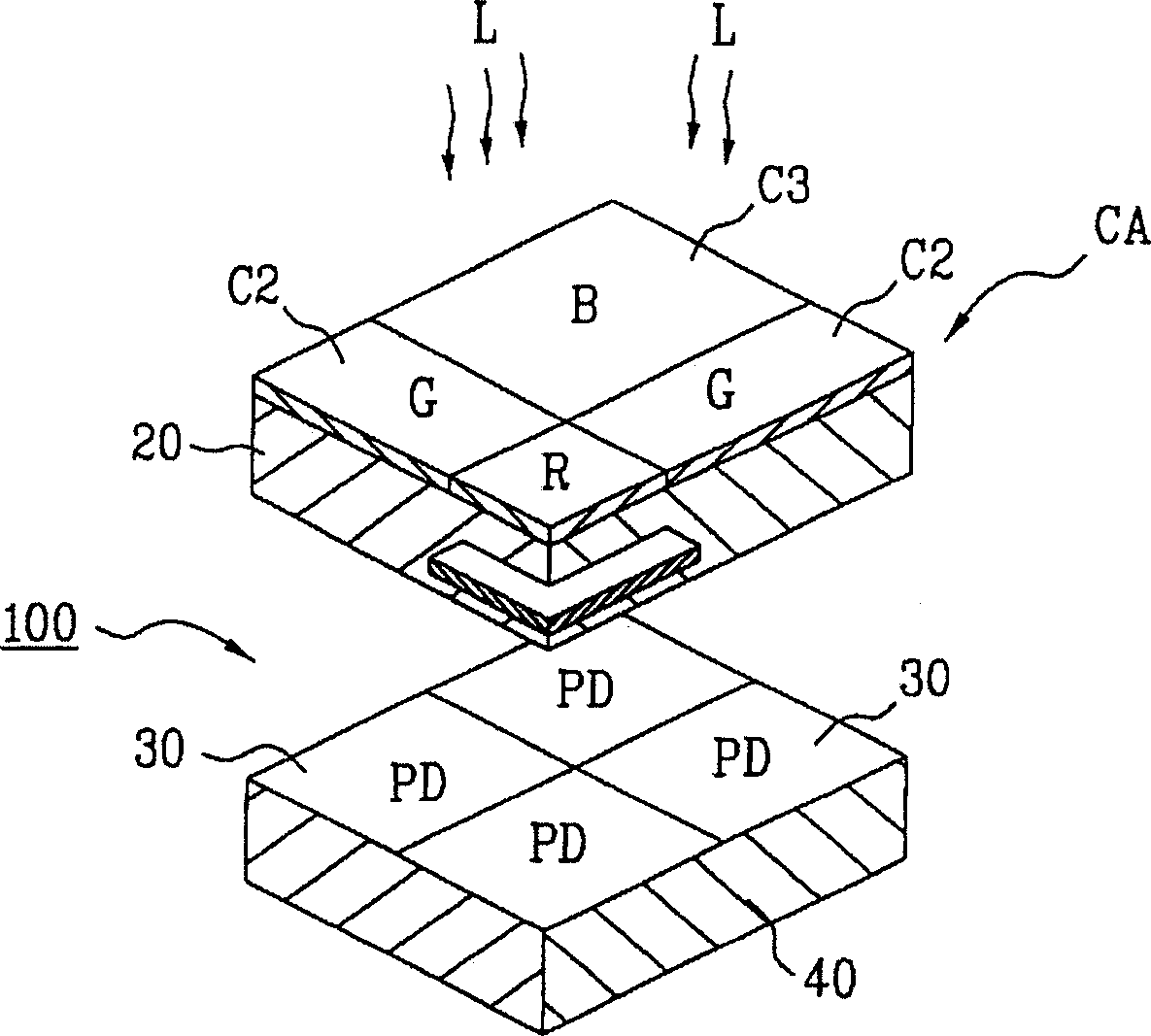

[0030] Such as image 3 As shown, the CMOS image sensor 100 of the present invention, that is, a CMOS image sensor for displaying a color image, includes a photodiode 30 formed on a semiconductor substrate 40 to generate and store a series of photocharges from external input light L, and a color filter array CA that colorizes externally input light and transmits the colored light to the photodiode 30 . In this case, the intermediate layer 20 is interposed between the color filter array CA and the photodiode 30 so as to transmit the light transmitted through the color filter array CA to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com