Process for prepareing SAPO-34 molecular siever

A technology of SAPO-34 and molecular sieve, applied in the field of preparation of SAPO-34 molecular sieve, can solve the problems of low crystallinity, small synthesis range, complex molecular sieve process, etc., and achieves improved catalytic activity, reduced synthesis cost, and simplified synthesis of molecular sieve by gas phase method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add 5.0g of aluminum isopropoxide to 13.95g of deionized water, stir vigorously, add 2.82g of phosphoric acid with a mass percentage of 85%, continue stirring for a period of time, and then add 3.06g of 30% by mass to it while stirring Silica sol (Jiangyin Guolian Chemical Industry), finally add 1.54g triethylamine. The ratio of each component is:

[0025] 1.25SiO2 2 : Al 2 o 3 : 1.0P 2 o 5 : 75H 2 O: 1.25Nt 3 N (triethylamine) After the synthesis solution is completely mixed, move it into a 40°C oven to evaporate the water to form dry glue, then grind the dry glue into powder, and place it on the upper part of the reaction kettle lined with polytetrafluoroethylene. At the same time, a mixture of water and morpholine (50:1.0 in molar ratio) was added to the bottom of the reaction kettle. After sealing, put it in a 170°C oven for gas phase reaction for 48 hours, and cool it in a natural state after the reaction. Finally, the sample is taken out, washed, dried an...

Embodiment 2

[0028] Add 3.06g of silica sol with a mass percentage of 30% to 5.0g of aluminum isopropoxide, stir it mechanically to make it evenly mixed, then add 1.76g of phosphoric acid with a mass percentage of 85%, and after fully mixing evenly, finally add 1.54g of three Ethylamine. The ratio of each component is:

[0029] 1.25SiO2 2 : Al 2 o 3 : 1.0P 2 o 5 : 1.25Et 3 The molecular sieve synthesis precursor obtained by N (triethylamine) does not need to be heated and evaporated to dryness, and is directly placed on the upper part of the reactor lined with polytetrafluoroethylene. )mixture. After sealing, place it in an oven at 170°C for 48 hours, and cool it in a natural state after the reaction. Finally, the sample is taken out, washed, dried and calcined to obtain the molecular sieve.

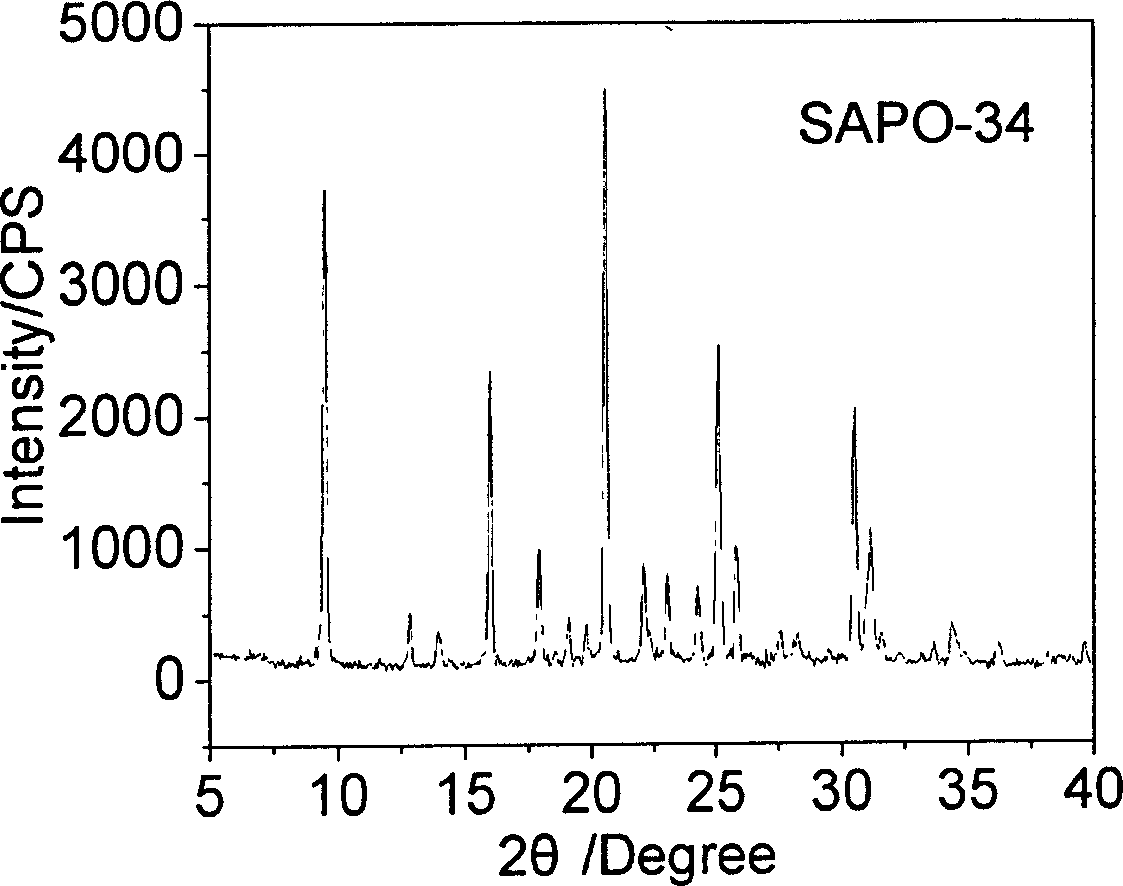

[0030] The samples were characterized by XRD, with and figure 1 The same crystal form has a crystallinity of 121%.

Embodiment 3

[0032] According to the preparation method and steps of Example 1, but change the organic amine species of the liquid phase part during the gas phase reaction, the liquid phase part is a mixture of water and triethylamine (the molar ratio is 10: 1.0), and the SAPO-34 molecular sieve crystallinity obtained at last 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com