Metal-graphite brush and motor including a metal-graphite brush

A metal graphite and electric motor technology, applied in the field of electric motors, can solve the problems of influence and unfavorable service life of the electric motor, and achieve the effect of reducing the degree of wear and the coefficient of sliding friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

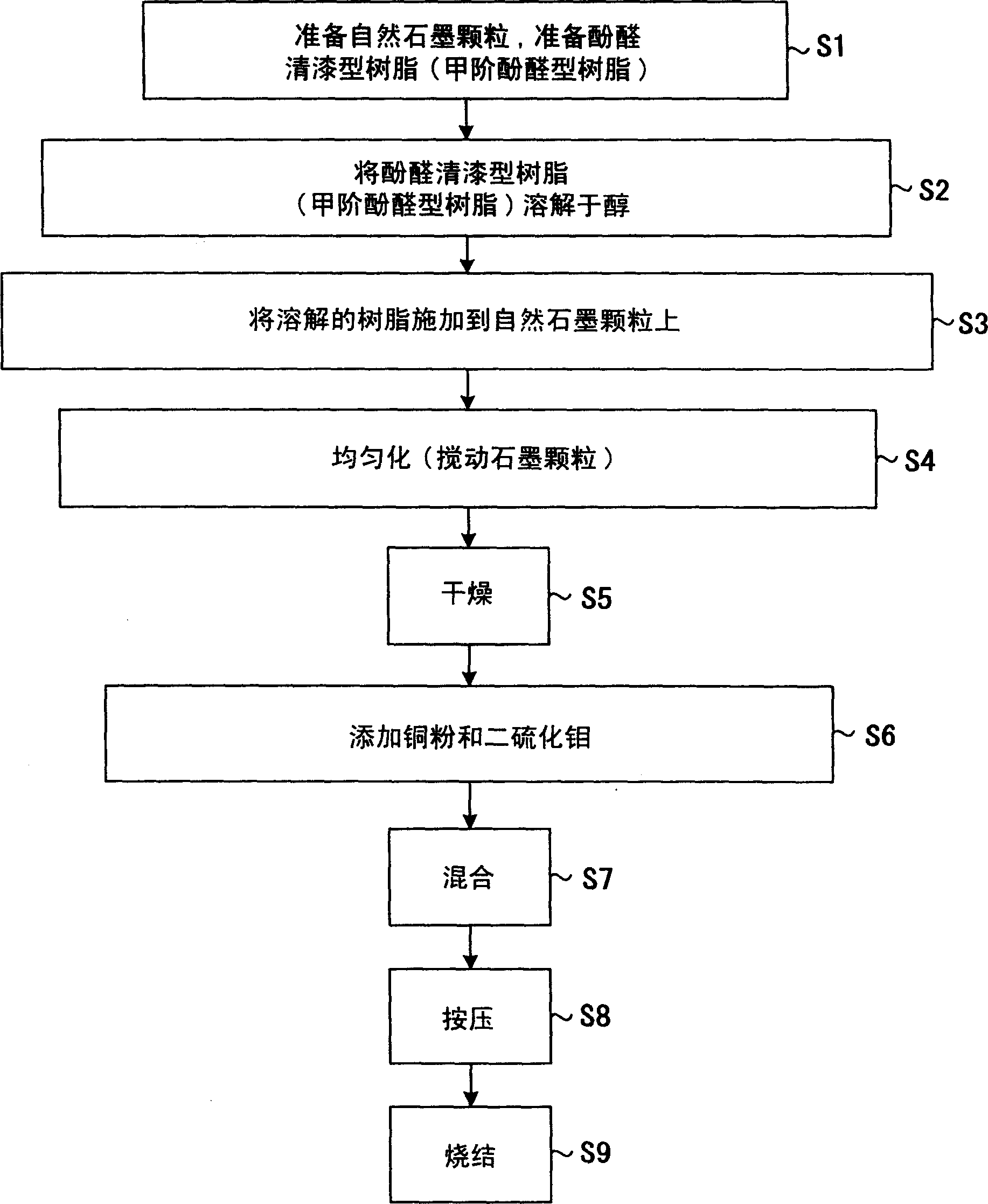

Method used

Image

Examples

example 1

[0074] The continuous operation of the slip ring with the metal grinding brush 1 was investigated, in which a polyethylene glycol monomethyl ether liquid 21 was penetrated as the liquid 21 . According to the research results, as attached Figure 13 As shown, when the operating temperature of the slip ring is in the range of about 120°C to 200°C, the amount of wear is limited to a low level; but when the operating temperature of the slip ring is higher than about 200°C, as long as the slip ring continues for a long time Running, the amount of wear will increase. In addition, in the temperature range of about 80-150°C, the amount of wear does not increase with the increase of the temperature of the slip ring in continuous operation. In other words, when the brush 1 operates in the temperature range of 80°C to 150°C, the amount of steam of polyethylene glycol monomethyl ether between the brush 1 and the sliding contact surface of the slip ring increases with the temperature of t...

example 2

[0076] The continuous operation of the slip ring with metal stone grinding brushes 1 was investigated, in which polyethylene glycol polypropylene glycol monomethyl ether was impregnated as liquid 21 . According to the research results, as attached Figure 14 As shown, when the operating temperature of the slip ring is in the range of about 120°C to 220°C, the amount of wear is limited to a low level; but when the operating temperature of the slip ring is higher than about 200°C, if the slip ring With continuous operation, the amount of wear will increase. In addition, when operating continuously in the temperature range of about 80-180°C, the amount of wear will not increase with the increase of the temperature of the slip ring. That is to say, when the brush 1 operates in the temperature range of 80°C to 180°C, the amount of steam of polyethylene glycol polypropylene glycol monomethyl ether between the brush 1 and the sliding contact surface of the slip ring increases with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com