Non-reversible circuit element and method of manufacture

A technology for circuit components and manufacturing methods, which is applied in the direction of electrical components, circuits, waveguide devices, etc., can solve the problems of poor processability, thickening of the ground terminal 55, poor grounding performance of the second yoke 54, etc., to improve processability, The effect of firm installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

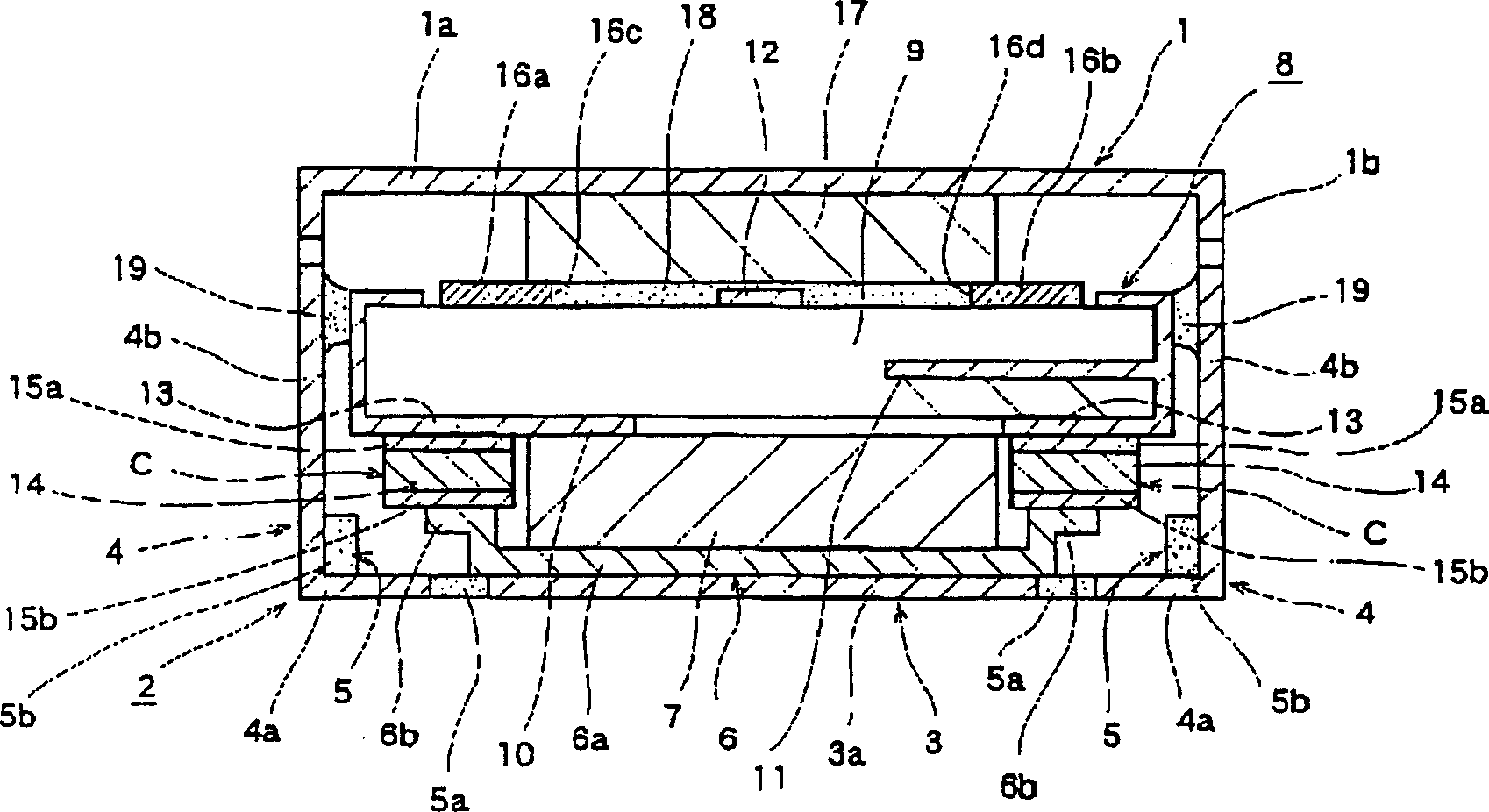

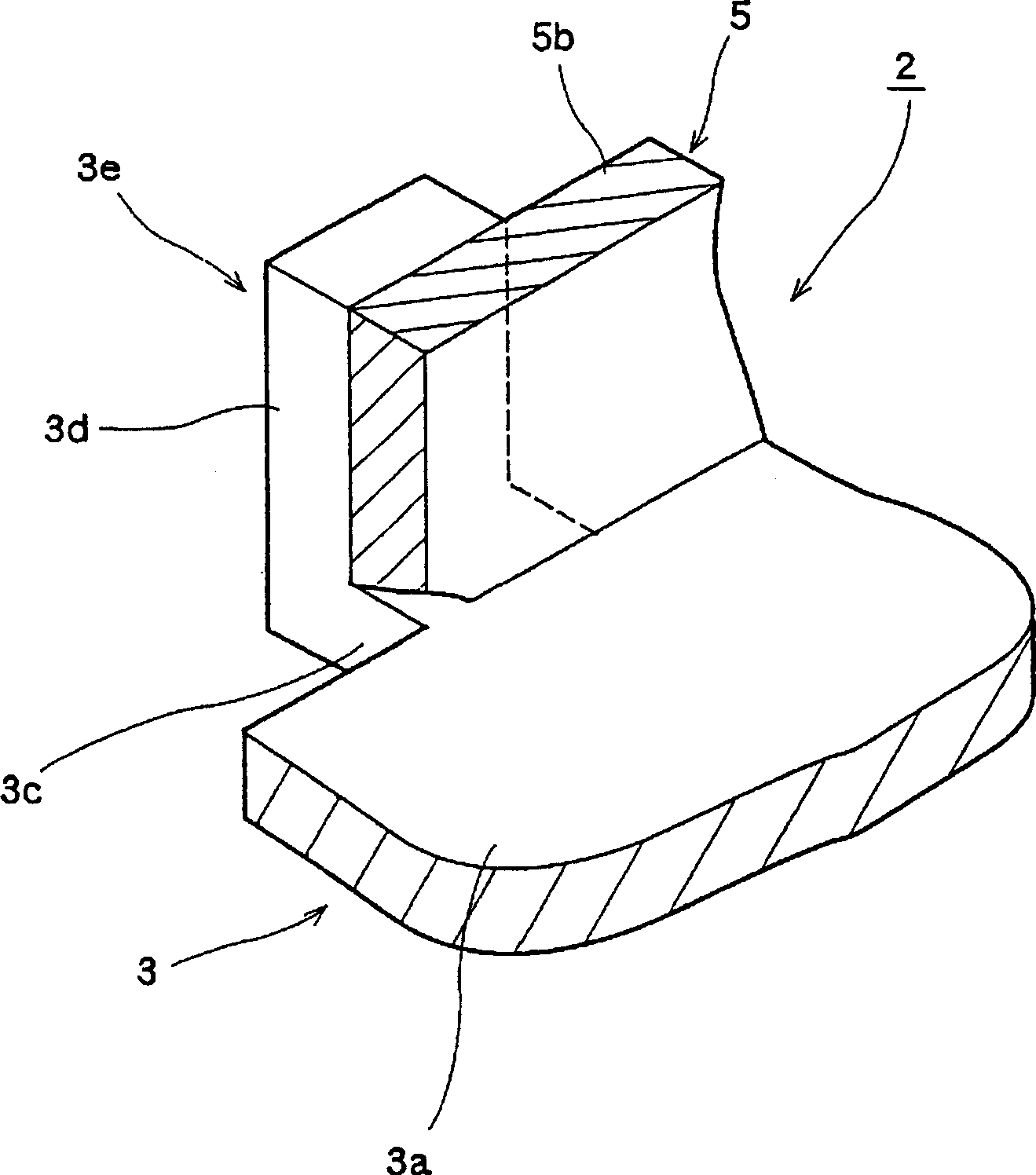

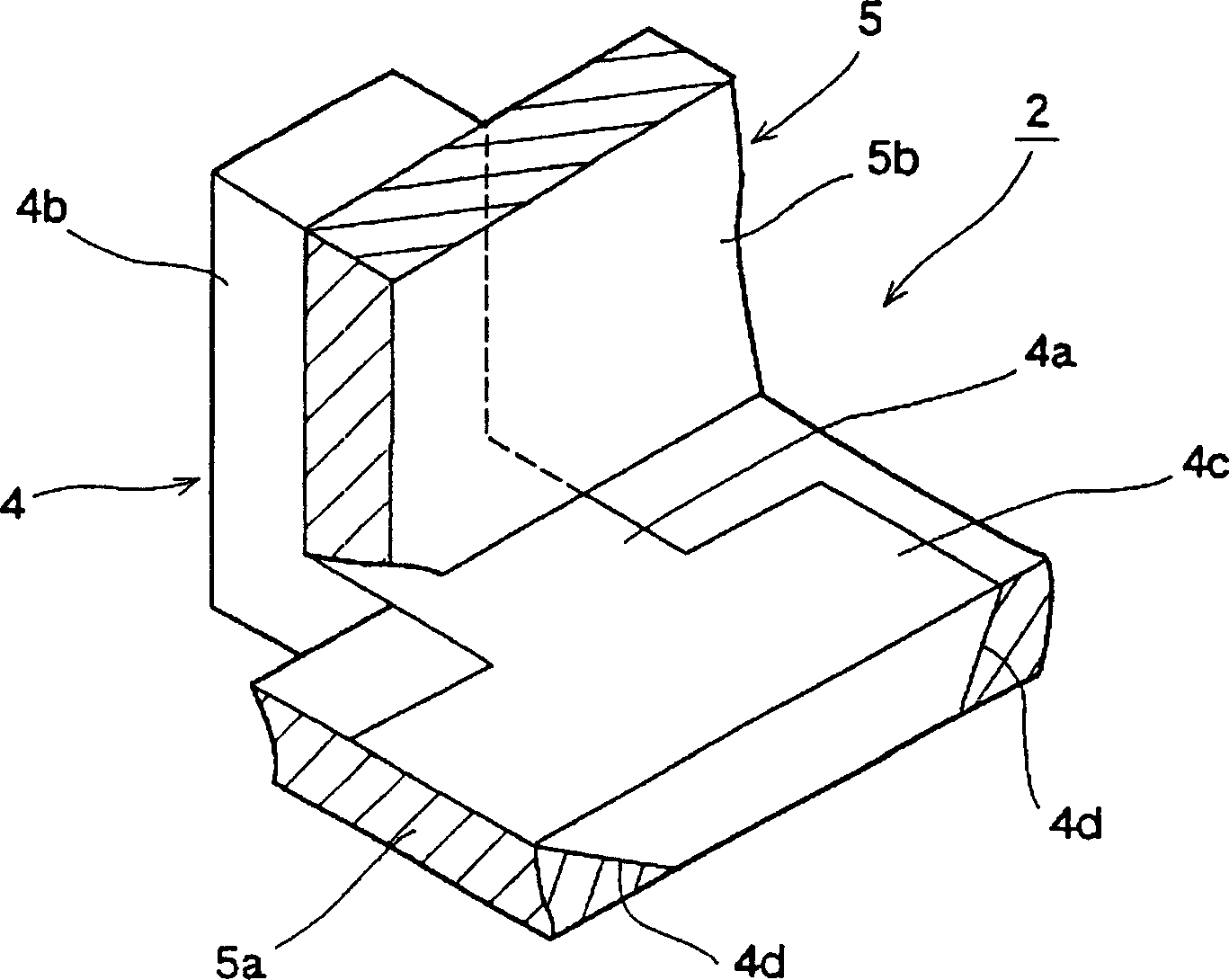

[0053] First explain the non-reciprocal circuit element of the present invention and its manufacturing method, figure 1 It is a sectional view of main parts of the non-reciprocal circuit element of the present invention, figure 2 It is an enlarged sectional view of main parts of the ground terminal of the non-reciprocal circuit element of the present invention, image 3 It is an enlarged sectional view of main parts of the input and output terminals of the non-reciprocal circuit element of the present invention, Figure 4 is a top view of the module body of the non-reciprocal circuit element of the present invention, Figure 5 It is an exploded perspective view of a magnet and a module body of a non-reciprocal circuit element of the present invention, Figure 6 It is an explanatory diagram showing the first step of the manufacturing method of the nonreciprocal circuit element of the present invention, Figure 7 It is an explanatory drawing which shows the 2nd process of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com