Backlight module and light conducting plate therefor

A technology of backlight module and light guide plate, which is applied in optics, nonlinear optics, instruments, etc., can solve the problems of high manufacturing cost and complex manufacturing process of backlight module, so as to reduce manufacturing difficulty and manufacturing cost, and improve light guiding ability. , to avoid the effect of shape distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

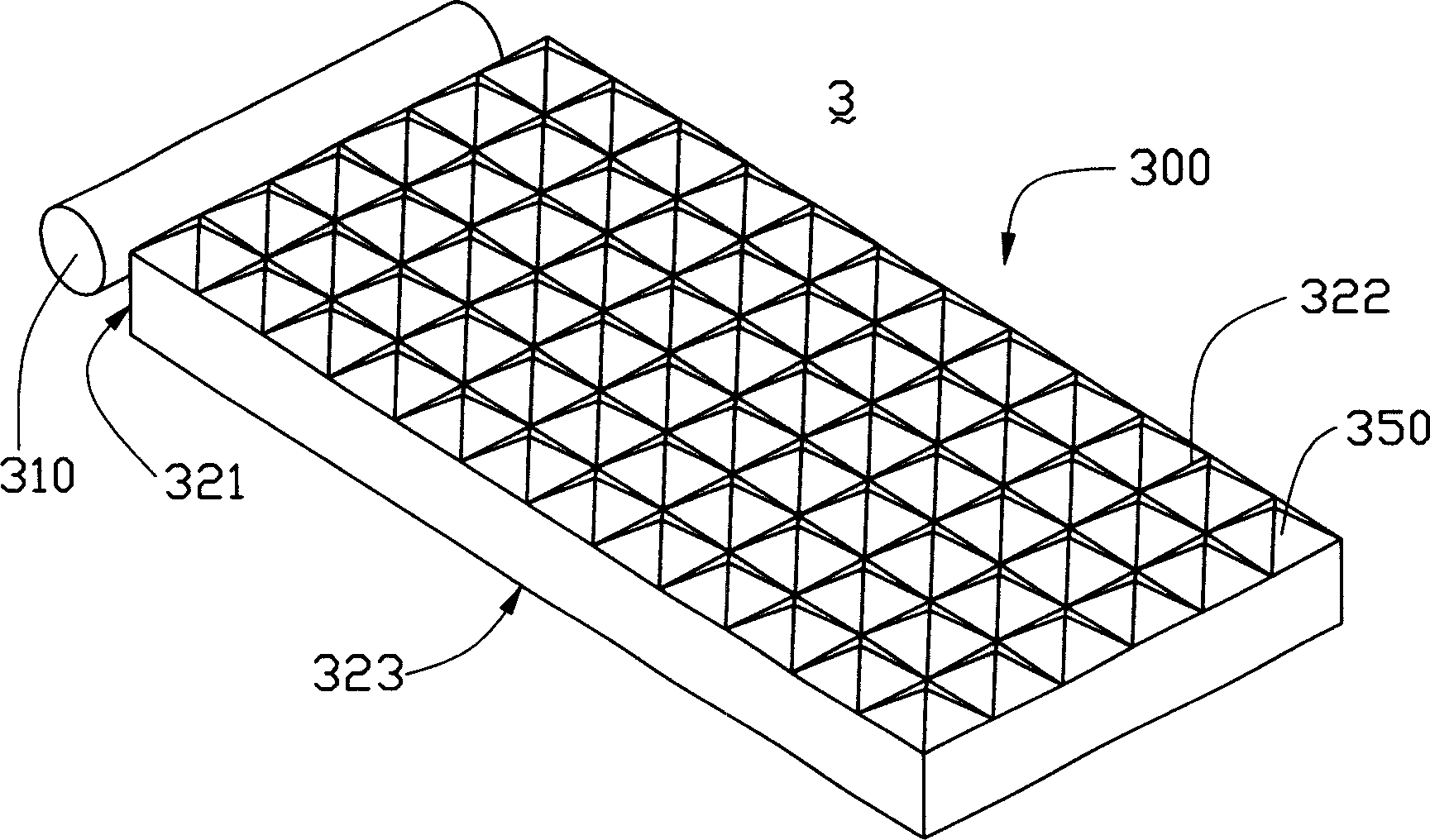

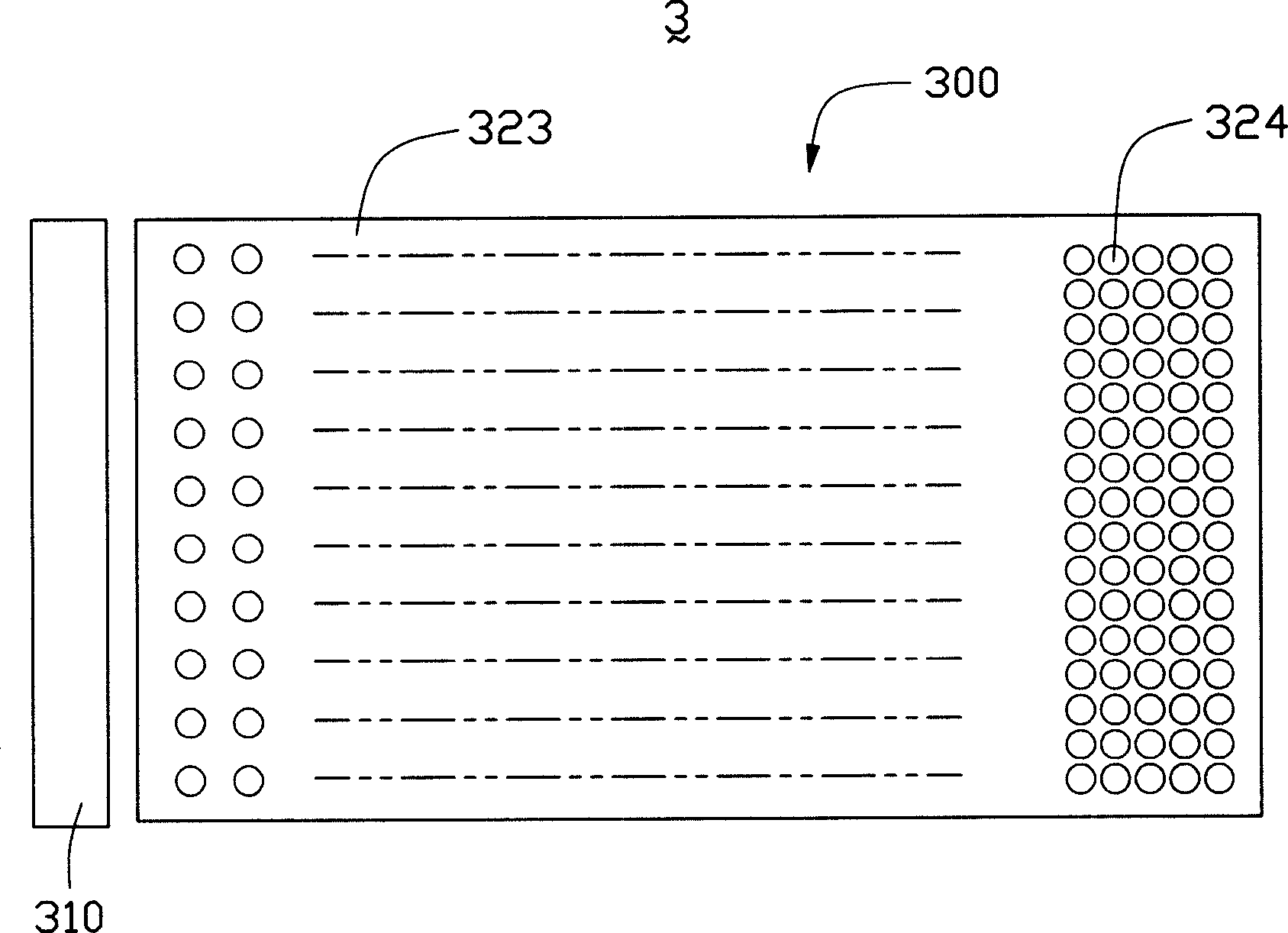

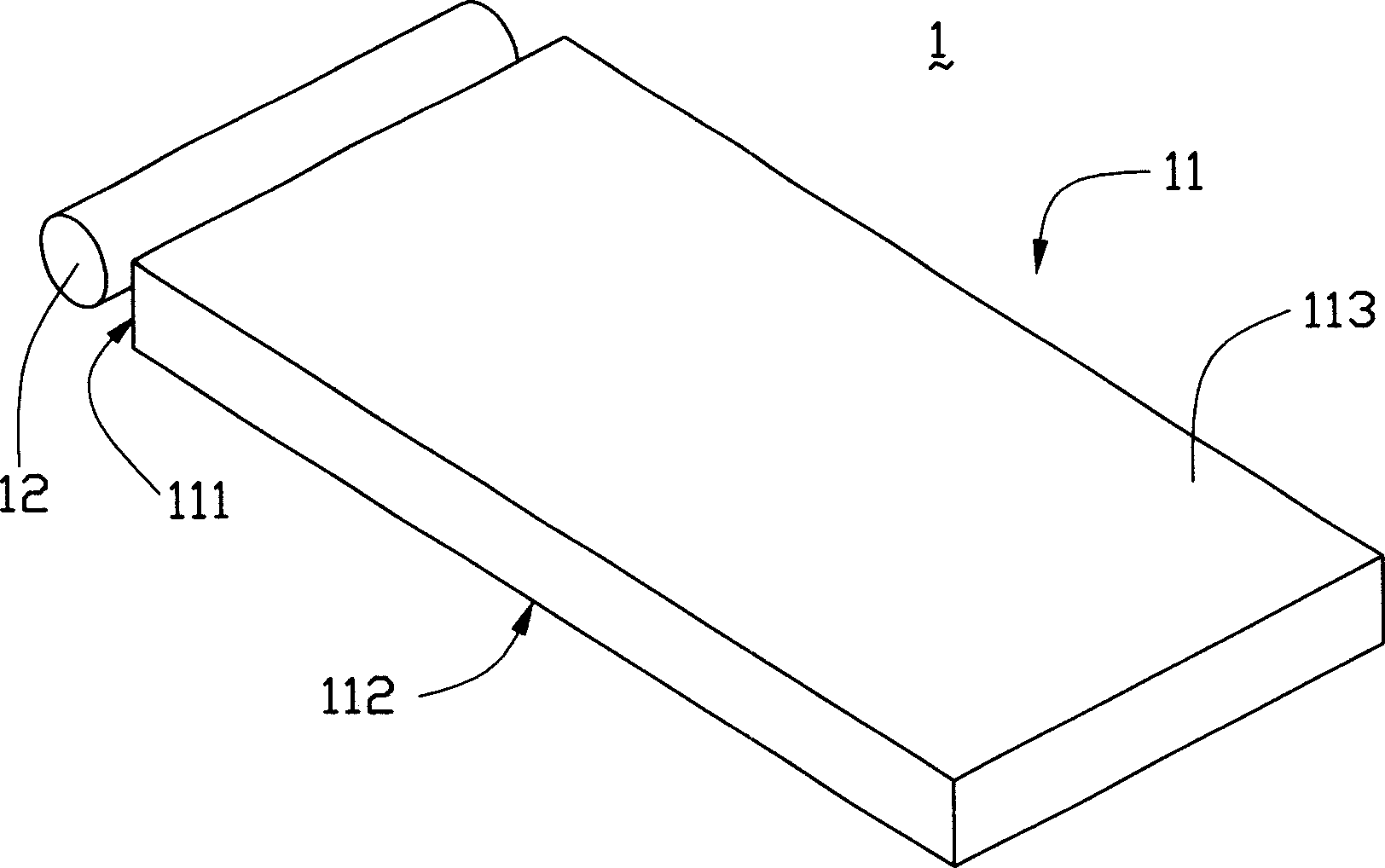

[0015] see image 3 and FIG. 4 are respectively an exploded perspective view of the backlight module of the present invention and a bottom view of the bottom surface of the backlight module. The backlight module 1 of the present invention includes a light guide plate 11 and a light source 12 , and the light guide plate 11 includes a light incident surface 111 , a bottom surface 112 and a light output surface 113 . The light incident surface 111 is used to receive the light beam emitted by the light source 12, and the bottom surface 112 is connected to the light incident surface 111. In order to improve the utilization rate of the light beam, the bottom surface 112 is coated with a reflective film (not shown), and the light exit surface 113 and the bottom surface 112 is opposite and guides the light beam in the light guide plate 11; the light source 12 is arranged opposite to the light incident surface 111 to provide light beams for the light guide plate 11; the bottom surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com