ZnS infrared window transparent increasing protective film and its preparing method

A technology of infrared window and protective film, which is applied in the direction of optical components, optics, instruments, etc., can solve the problems of thin film refractive index and thickness error, easy design and difficult preparation, etc., and achieves simple preparation method, ideal anti-reflection effect and good application prospect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The structure of embodiment 1 double-layer anti-reflection protective film system

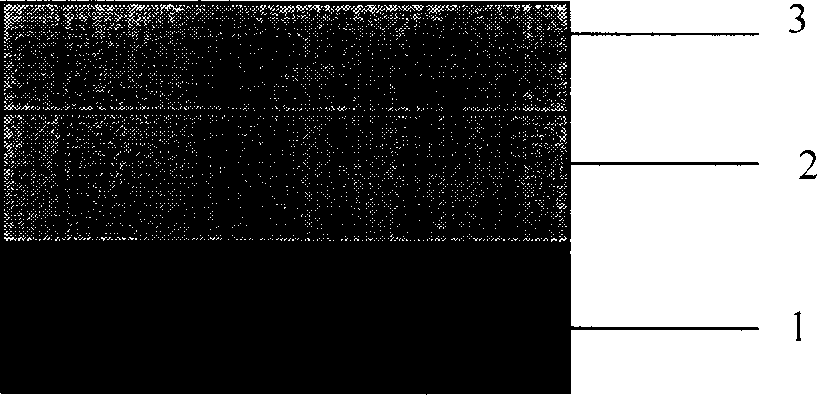

[0022] Lambda of the present invention 0 / 4-λ 0 / 4 The structure of the double-layer antireflection protective film system is as follows: figure 1 shown. The entire double-layer anti-reflection protective film system is composed of a ZnS substrate 1, a high-refractive-index film 2 in the first layer, and a low-refractive-index film 3 in the second layer. The optical thicknesses of high refractive index film 2 and low refractive index film 3 are both λ 0 / 4=2~3μm.

[0023] The high refractive index film 2 and the low refractive index film 3 are Ge 1-x C x Material, wherein x=0.2~0.6.

[0024] Due to the refractive index of ZnS (n 1 =2.2) is small, and the Ge that can be obtained in the current experiment 1-x C x The refractive index of the film is relatively large, so a layer of optical thickness λ can be coated on the ZnS substrate first. 0 / 4, the refractive index is n 2 thi...

Embodiment 2

[0025] Embodiment 2 The preparation method of the ZnS infrared window anti-reflection protective film of the present invention

[0026] Experimentally, using radio frequency magnetron sputtering method to CH 4 / Ar as the discharge gas to synthesize Ge on the ZnS substrate 1-x C x Double-layer film, the deposition system is the FJL-450B type magnetron sputtering and ion beam composite sputtering equipment produced by the Shenyang Scientific Instrument Company of the Chinese Academy of Sciences, and the RF power frequency is 13.56MHz. Discharge gas CH 4 , Ar is sent from the bottom of the vacuum chamber, and the two gases are respectively passed through the gas regulating valve and flow meter, and then mixed into the vacuum reaction chamber at a certain ratio, and a vacuum pump is connected under the reaction chamber system to control the pressure of the reaction chamber at 0.5 ~2.0 Pa. After glow discharge, CH 4 , The positive ions generated by Ar ionization bombard the Ge...

Embodiment 3

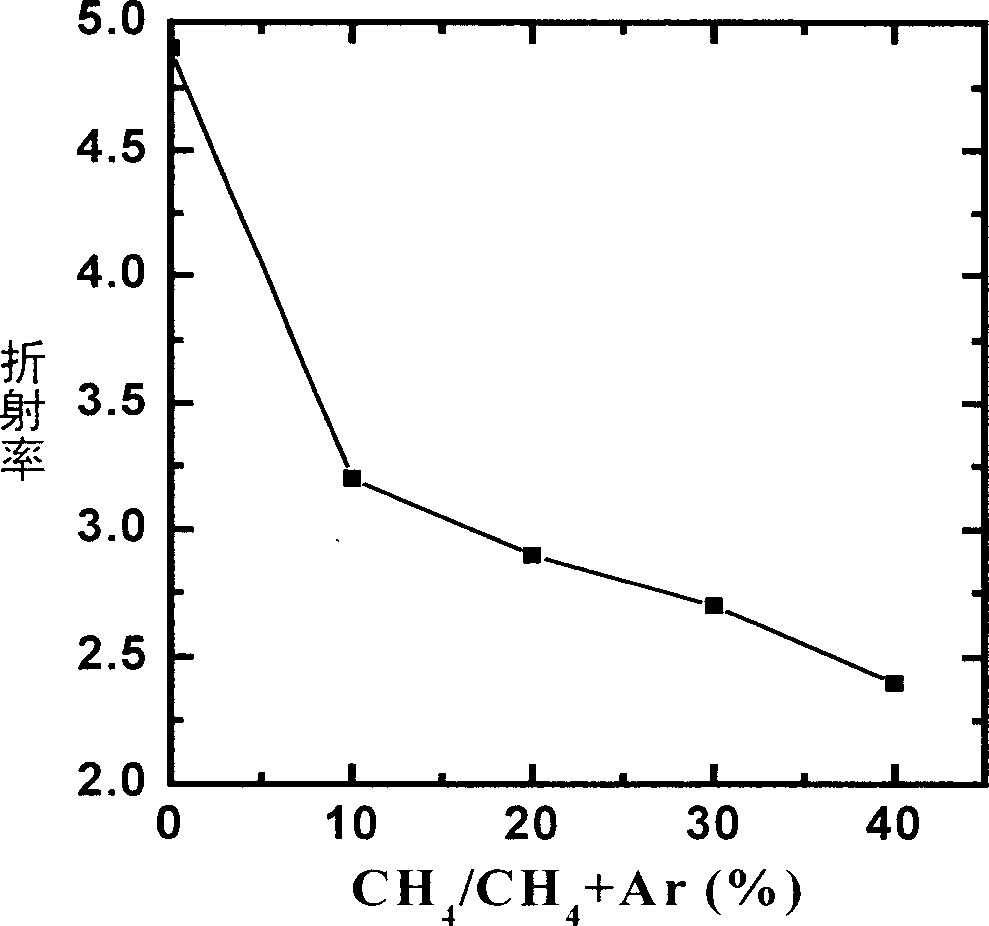

[0028] Example 3Ge 1-x C x Refractive index n and CH of material film 4 / (CH 4 +Ar) The experimental curve of the flow ratio relationship

[0029] After many experiments, the refractive index n~CH 4 / (CH 4 +Ar) curve such as figure 2 shown. With CH 4 / (CH 4 +Ar) flow ratio increases, Ge 1-x C x The refractive index n of the film becomes smaller accordingly. in CH 4 / (CH 4 +Ar)=5-40%, the refractive index n of the film is in the range of 2.4-4.0. According to the experimental curve, the n of the high refractive index film 2 and the low refractive index film 3 can be selected respectively 2 and n 3 After that, the corresponding CH 4 / (CH 4 +Ar) ratio, which determines the experimental parameters.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Optical thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com