Amorphous polystyrene base gas sensitive conductive composite material and preparation method thereof

A conductive composite material, polystyrene-based technology, applied in the field of amorphous polystyrene-based gas-sensitive conductive composite material and its preparation, to achieve the effects of reduced percolation value, high sensitivity, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

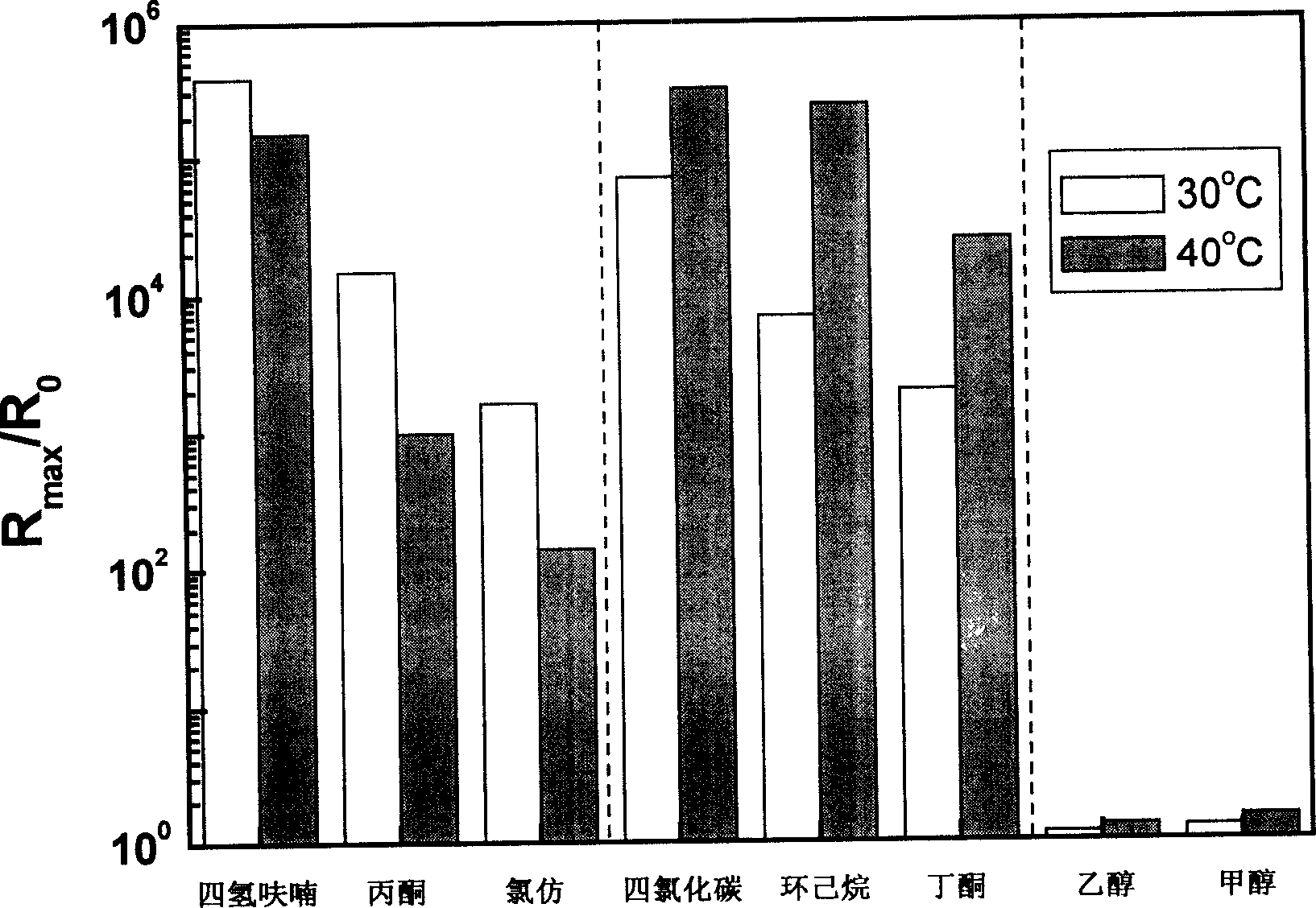

Image

Examples

Embodiment Construction

[0024] The composition ratio of Examples 1-7 is shown in Table 1, and the specific steps of its preparation method are as follows:

[0025] ①Add a certain amount of newly treated styrene monomer and 0.6wt% initiator into the reactor, and stir with nitrogen gas until the initiator is completely dissolved;

[0026] ② Add conductive filler with a mass fraction of 8.5wt% to 21.4wt% according to the calculated amount, stir with nitrogen for 10 minutes, then raise the temperature to 85°C and stir for 4 hours, and react at 150°C for 2 hours;

[0027] ③ Cool down to 80°C, add an appropriate amount of polystyrene good solvent and continue stirring for 1 hour, then cool to room temperature;

[0028] ④ Apply the obtained sticky substance on a self-made glass electrode plate, dry it and vacuum-dry it at room temperature for 48 hours to obtain a composite material electrode.

[0029] Comparative examples 1 to 7 are prepared by blending industrial polystyrene and conductive filler with met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com