Filtration and washing technology in preparing metal or non metal fine granular powder

A non-metallic, fine particle technology, applied in the technical field of filtering and washing by precision microporous filter, it can solve the problems of complex equipment, waste of washing liquid, low production efficiency, etc., reduce the consumption of washing liquid and improve the collection of fine powder Rate, washing efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

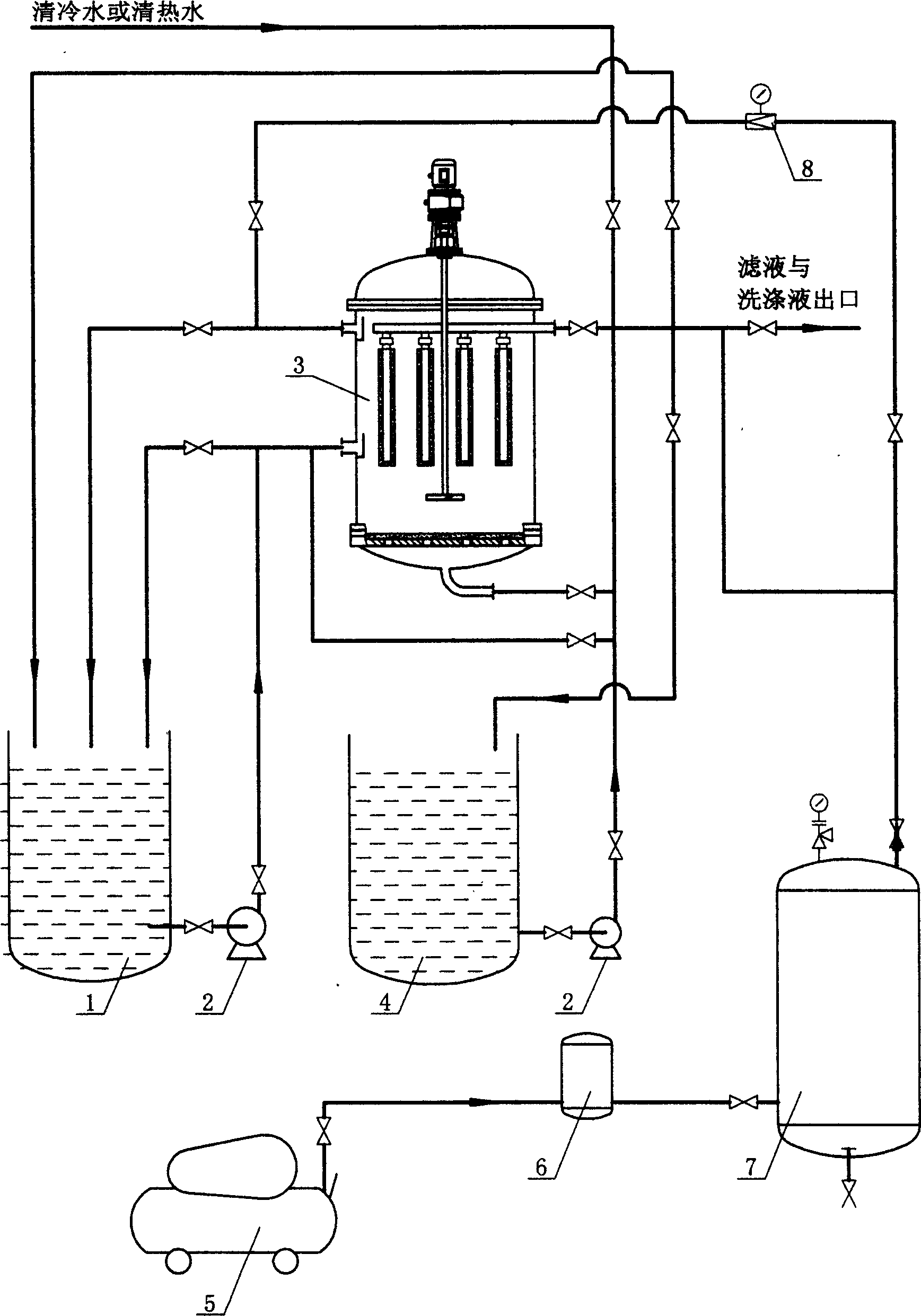

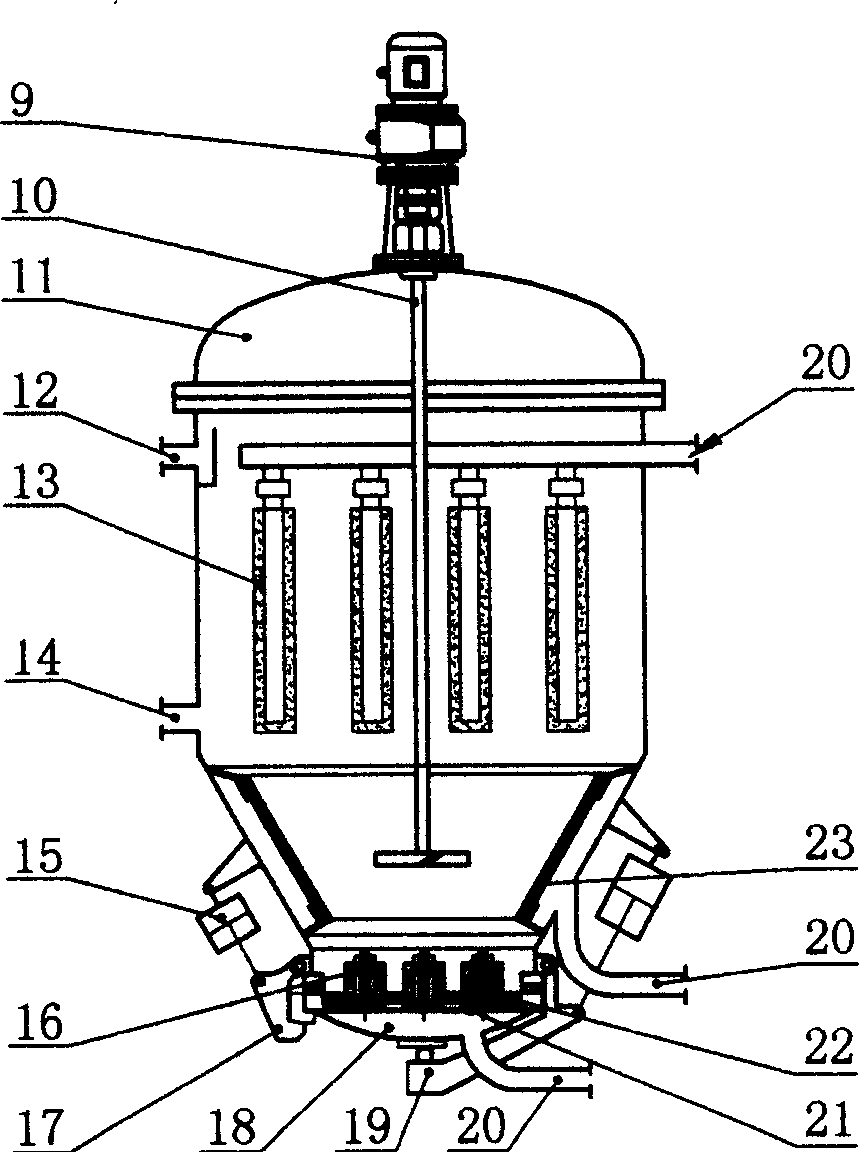

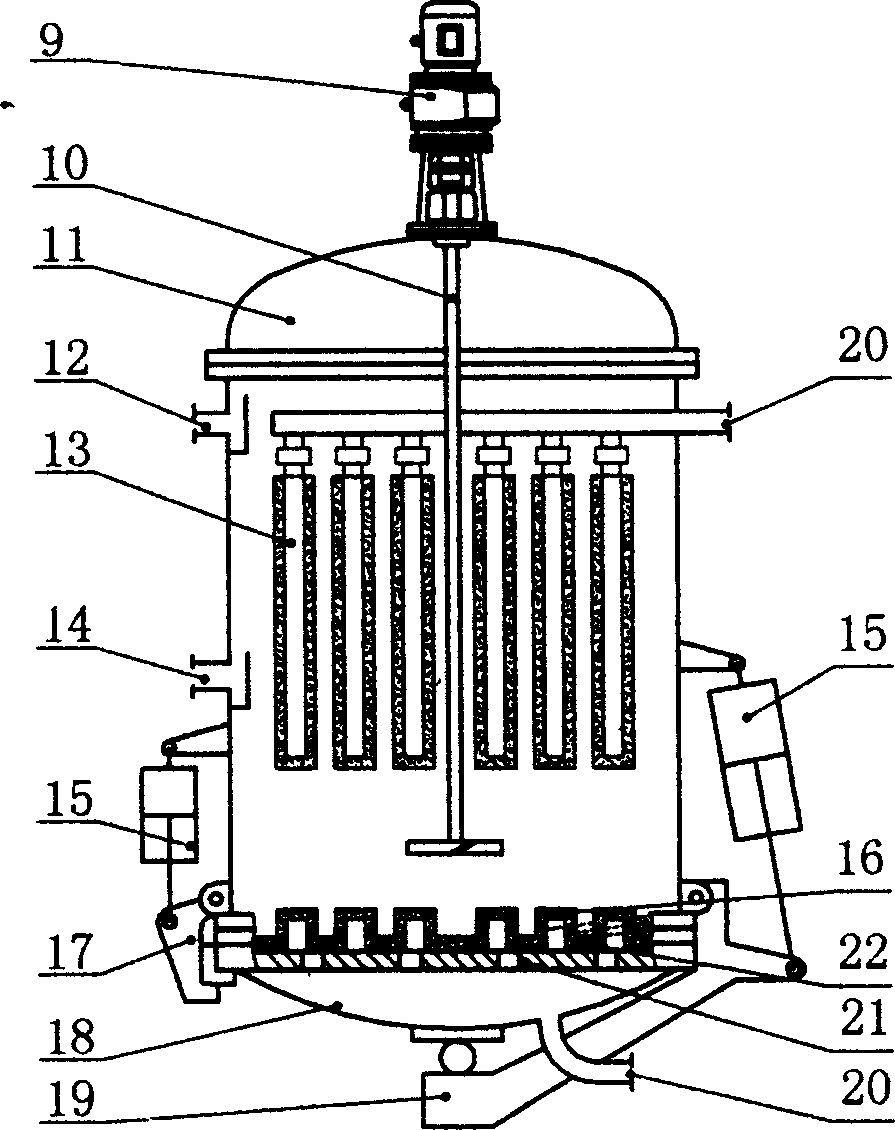

[0020] like figure 1 As shown, the filtration and washing process for preparing metal or non-metal fine particle powder of the present invention comprises the following devices: powder slurry tank 1, pump 2, precision microporous filter 3, washing liquid storage tank 4, air compressor 5. Air purifier 6. Compressed air storage tank 7. Pressure reducing valve 8. Precision microporous filter 3 is the main equipment of this process, such as figure 2 , 3 As shown, it includes speed regulating motor 9, stirring paddle 10, top cover 11, vent 12, rigid microporous filter tubes 13, 16, slurry inlet 14, air cylinder or hydraulic cylinder 15, locking hook 17, bottom cover 18 , Support arm 19, filtrate outlet 20, flower plate 21, rigid microporous filter plate 22, rigid microporous filter cone shell 23. Rigid microporous filter tube 13 forms the first layer of filter area, rigid microporous filter cone shell 23 forms the middle layer of filter area, rigid microporous filter tube 16 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com