Structure of active carbon fibrous adsorptive bed with static charge reinforcing control

A technology of activated carbon fiber and activated carbon fiber cloth, which is applied in the field of high power density adsorption bed and can solve problems such as rising

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

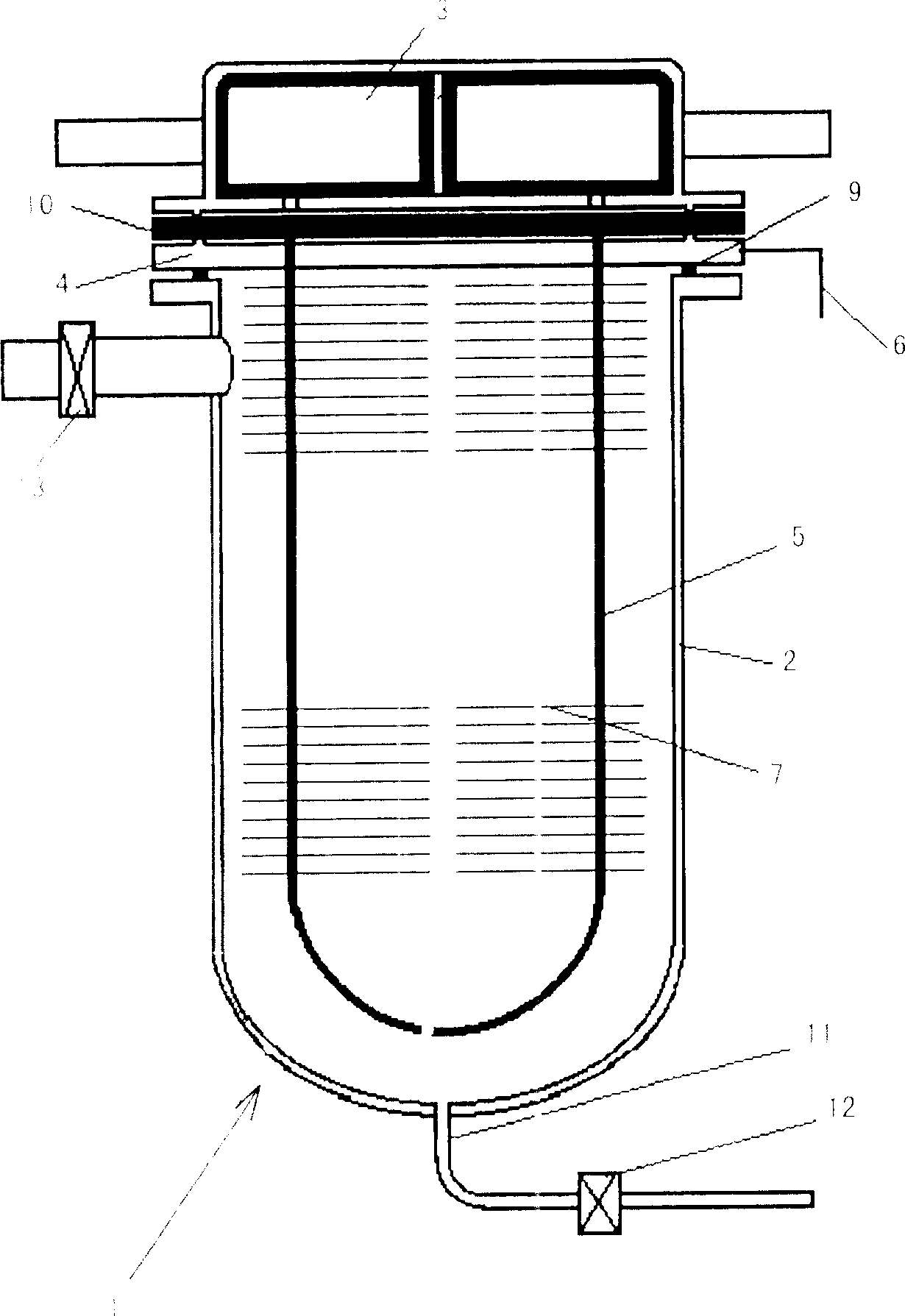

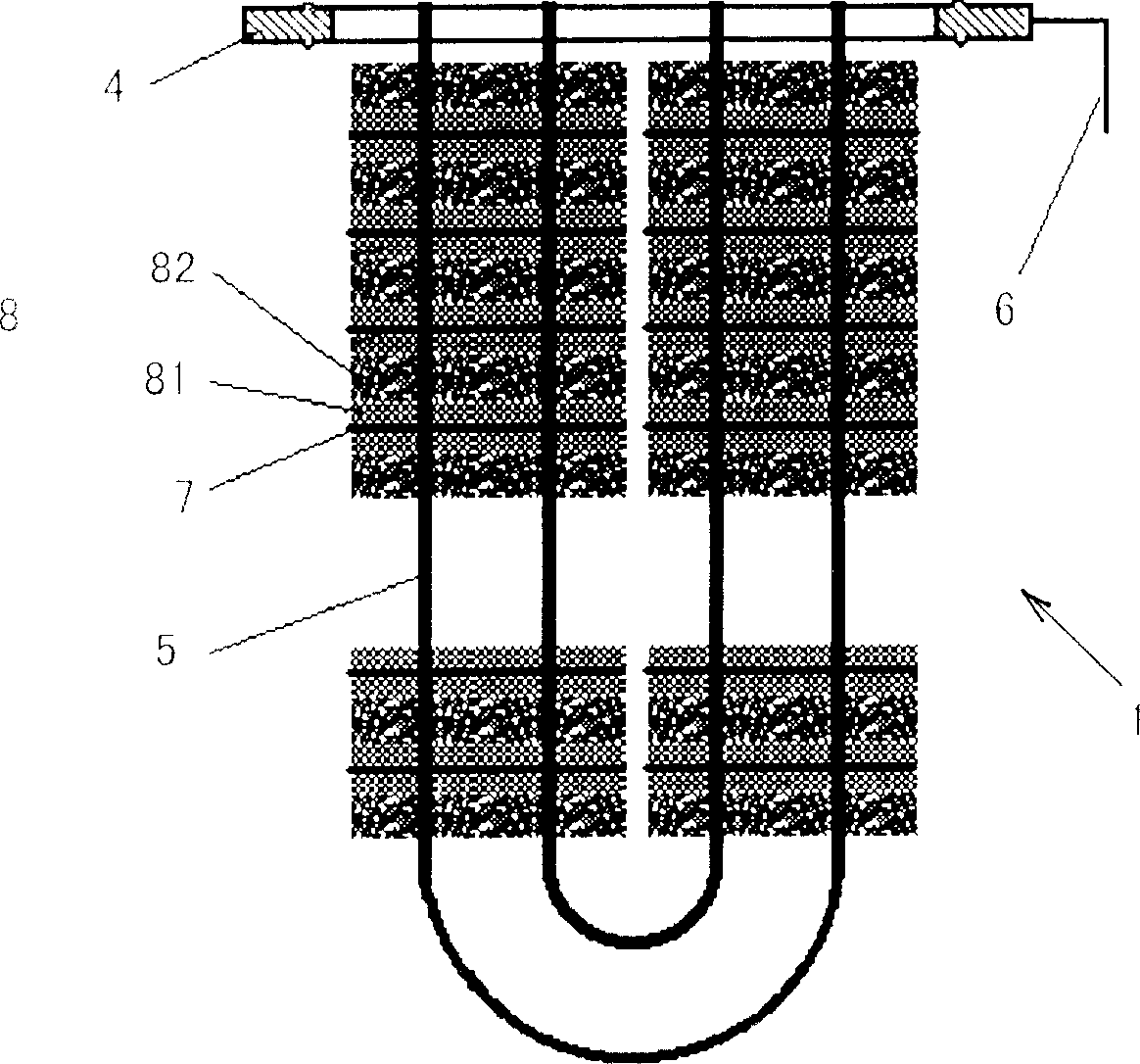

[0019] For further describing structural feature and function of the present invention, below in conjunction with accompanying drawing explanation is as follows:

[0020] see figure 1 , the core end plate 4, the metal U-shaped tube 5, the electrostatic input terminal 6, the aluminum fin 7 and the attachment 8 on the fin constitute the adsorption bed core 1, and the core 1 is connected with the shell by polytetrafluoroethylene or fluororubber material The body 2 and the head 3 are electrostatically insulated, and the input or release of electrostatic charges to the core body 1 can only be performed through the electrostatic input terminal 6 . The polytetrafluoroethylene or fluororubber material includes an electrostatic insulating sealing ring 9 and an electrostatic insulating plate 10. The electrostatic insulating sealing ring 9 is placed between the shell 2 and the core end plate 4, located on the lower surface of the core end plate 4, and is connected to the shell The open ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com