Method for preparing cyclopentanol by hydration of cyclopentene

A technology of cyclopentene water and cyclopentanol, which is applied in hydroxyl addition preparation, organic chemistry and other directions, can solve the problems of low reaction conversion rate and large circulation of raw material cyclopentene, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

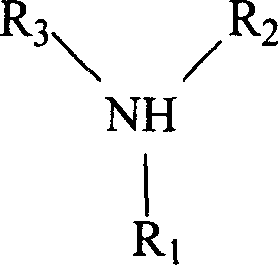

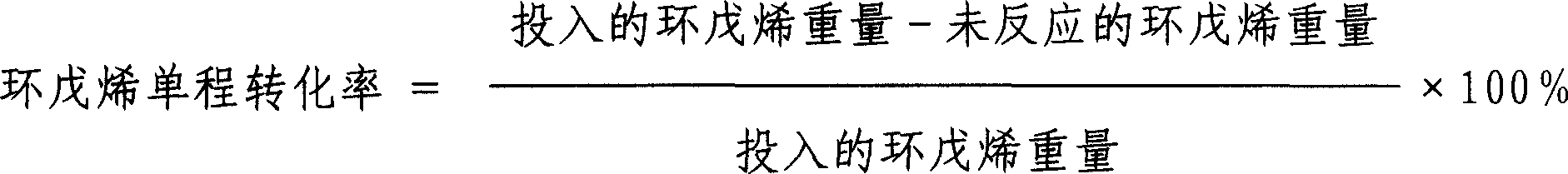

[0017] The hydration reaction was carried out in a stainless steel single-tube reactor of φ25mm×1000mm. A 300-mesh stainless steel mesh was placed at the bottom of the reactor, and then 100ml of main catalyst strong acidic cation exchange resin was loaded, and the air in the single-tube reactor was replaced three times with nitrogen. Cyclopentene, water and co-catalyst trialkylamine are sent into the preheater according to the required ratio by a metering pump, and the materials are heated to 130-180°C. The preheated material enters the single-tube reactor for hydration reaction, the reaction temperature is controlled at 130-180°C, and the reaction pressure is 1.0MPa-3.0MP in absolute pressure. The reaction product was cooled to room temperature, allowed to stand and separated into layers, and the water phase material and the oil phase material were distilled and separated to obtain the product cyclopentanol and unreacted cyclopentene. Water and unreacted cyclopentene are retu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com