Double component nanometer material spray gun

A two-component, spray gun technology, used in spray devices, liquid spray devices, etc., can solve problems such as easy-to-adhesion blocks and blockages, uneven mixing, inconvenient assembly, disassembly, cleaning or replacement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

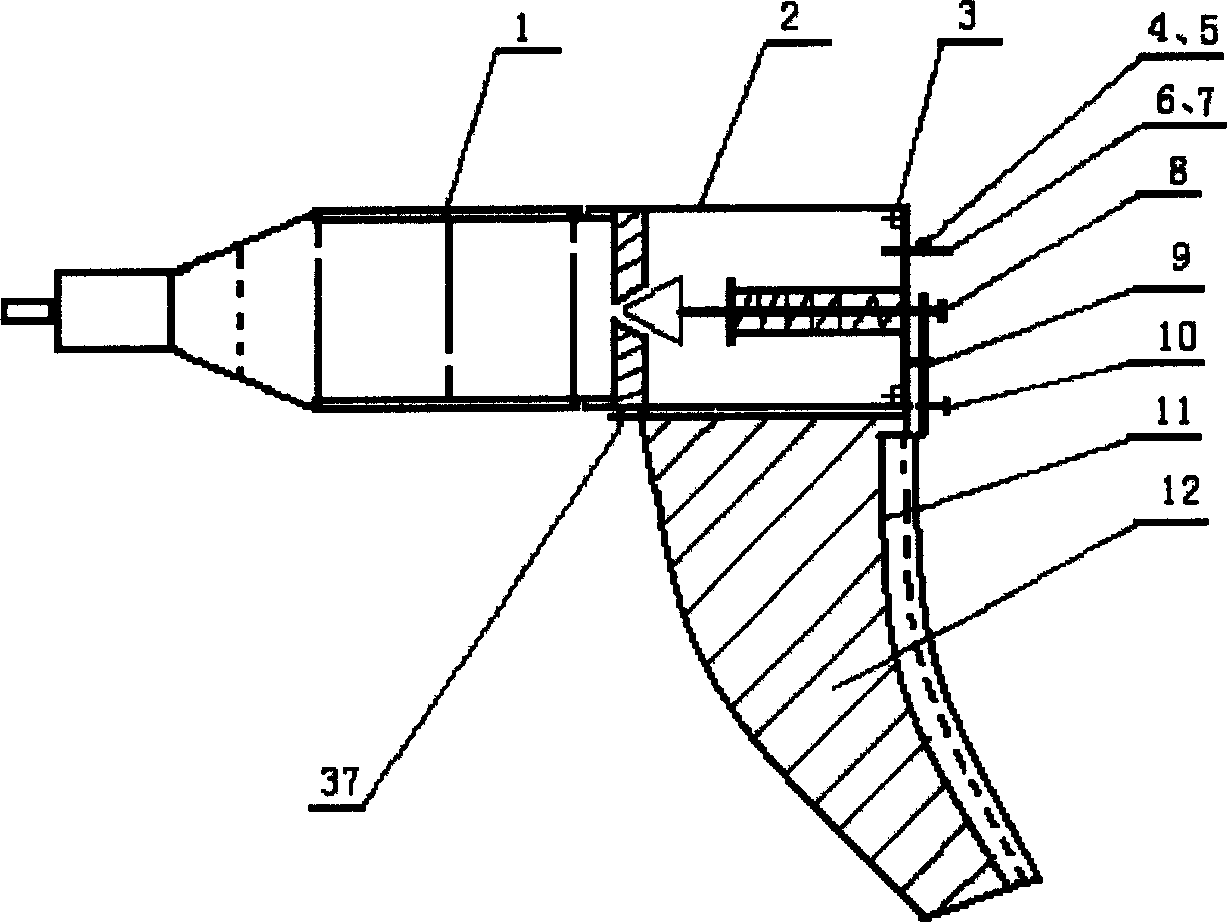

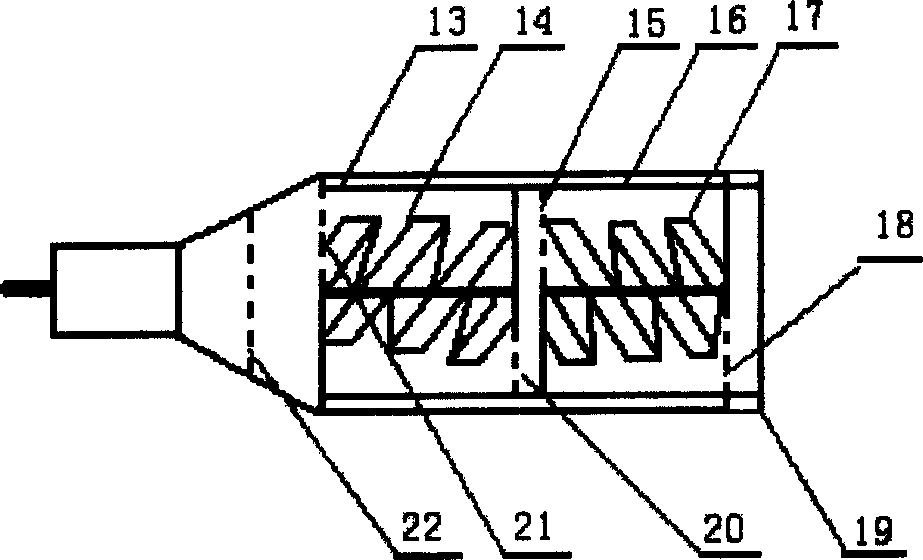

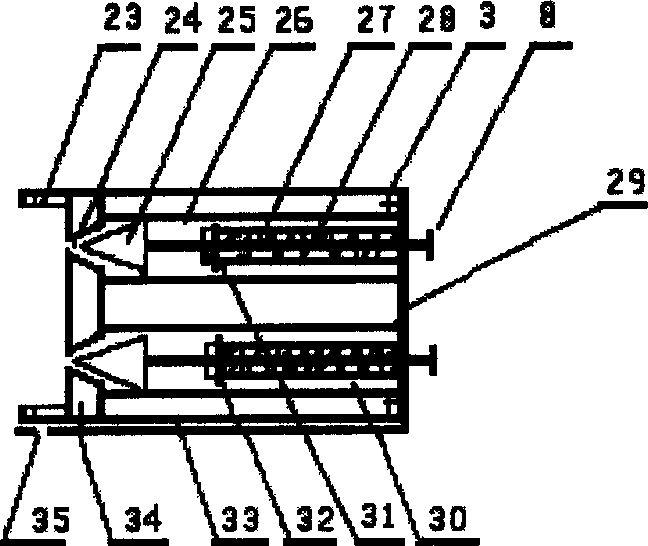

[0021] The present invention is based on the technical scheme and its attachments Figure 1~6 , Using high-quality steel, refined by mechanical manufacturing methods, the connection part of the nozzle and the gun body is connected by a matching thread, but the entire spray gun system should be made according to the pressure system, and the production and installation of the spray gun and parts should be accurately matched. In addition, the spray gun is composed of a pressured two-component nanomaterial storage tank and a guide tube connected to the spray gun.

[0022] in Figure 1~6 The main structure of the entire spray gun is: there is a spray head 1 with a positive rotation mixing reaction chamber 16 and a reverse rotation mixing reaction chamber 13; there is a spray head 1 connected to the spray head 1 with a first gun body silo 26 It is connected with the second gun body silo 30, the first gun body silo introduction channel 6 and the second gun body silo introduction channel 7 ...

Embodiment approach 2

[0028] If the spray gun made according to the first embodiment is used for filling and plugging the gaps in coal mine roadways, mining areas, etc., a nano material storage tank should be made, and a material storage tank should be filled or injected with polyurethane elastic prepolymer 3~ 5Kg and trichloroethylene solvent 0.5~2.5MPa, another material storage tank is filled or injected with diamine or glycol crosslinking agent 0.5~2Kg, the pressure in the material storage tank is 1.5~2.5MPa, in the material storage tank There are valves and guide tubes connected to the spray gun. When spraying, open the valve on the material storage tank, and then introduce the first gun body silo on the spray gun body into the flow channel 6 and the second gun body silo into the flow channel The first gun body silo introduction runner control valve 4 and the second gun body silo introduction runner control valve 5 on 7 are opened and adjusted the material ratio, and then adjust the size of the spr...

Embodiment approach 3

[0030] Using the spray gun made in Embodiment 1, according to the method of use in Embodiment 2, if a temporary insulation tent is set up in the rescue and relief process, the nano material storage tank can be filled or injected with MDI: 5-10kg, aerosol (one Chlorodifluoromethane): 0.5~1.0kg, pressure: 1.5~2.5MPa; another material storage tank (1) is flushed with spraying combination polyether; 4~8kg, aerosol (monochlorodifluoromethane): 2 ~3kg, pressure: 1.5~2.5MPa, spraying on the frame with straw mat, woven belt, canvas, etc. as the base material can quickly build a temporary tent with cold insulation and heat preservation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com