A homogeneous mixed co-precipitation device for rare earth ore precipitation

A technology of uniform mixing and precipitation device, which is applied in the direction of improving process efficiency, etc., can solve the problems of uneven mixing of material and liquid, single mixing method of mixed liquid, etc., and achieve the effect of good mixing effect, large stirring range and sufficient mixing reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

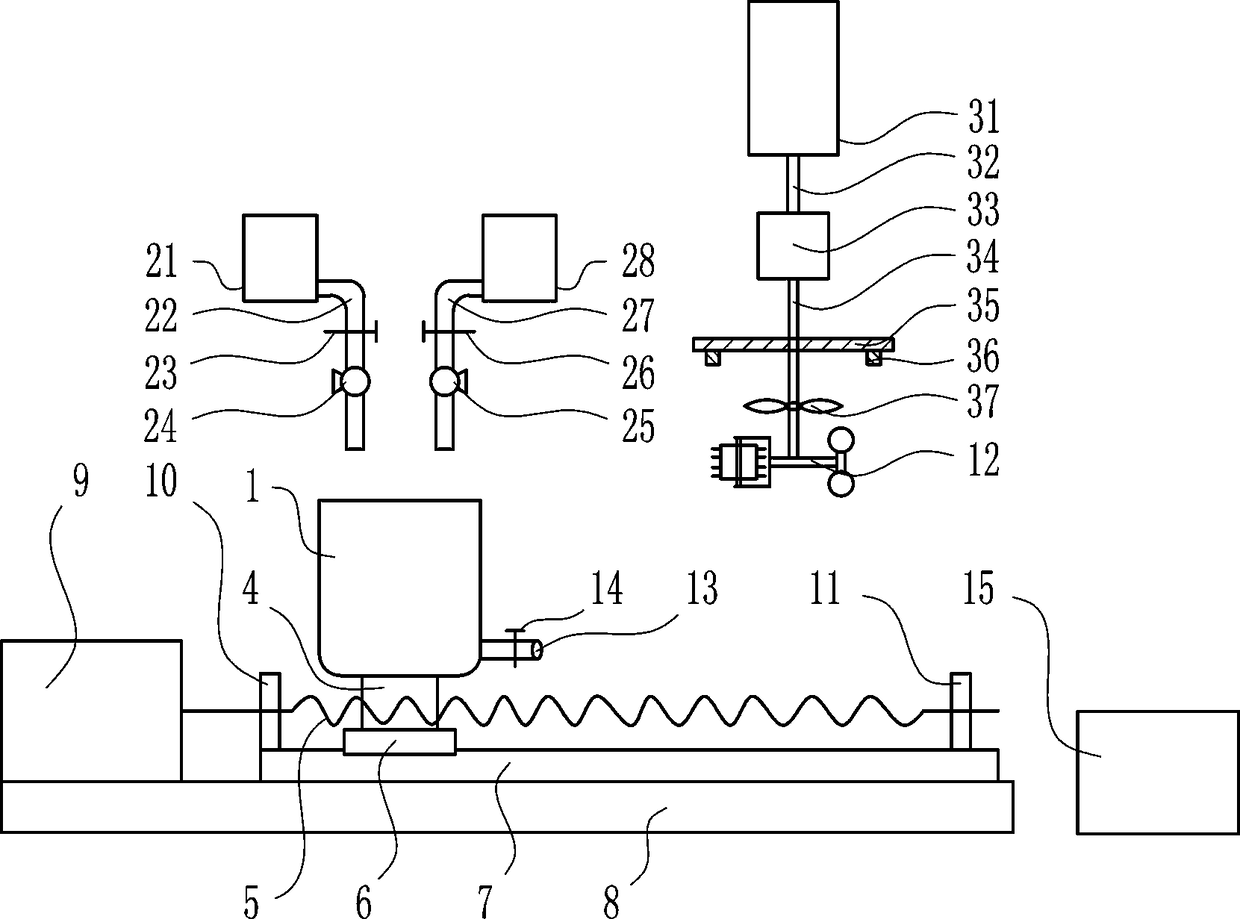

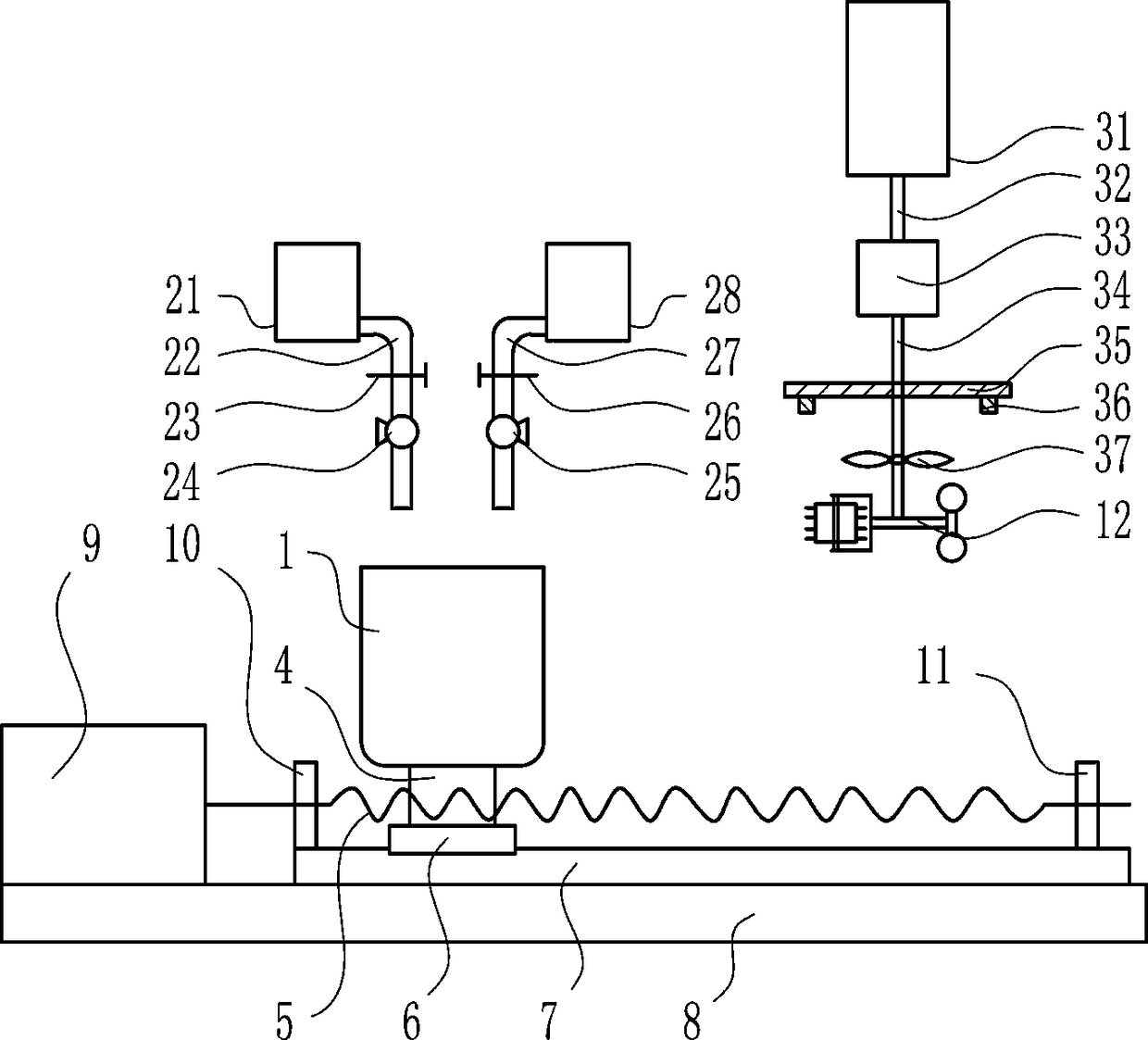

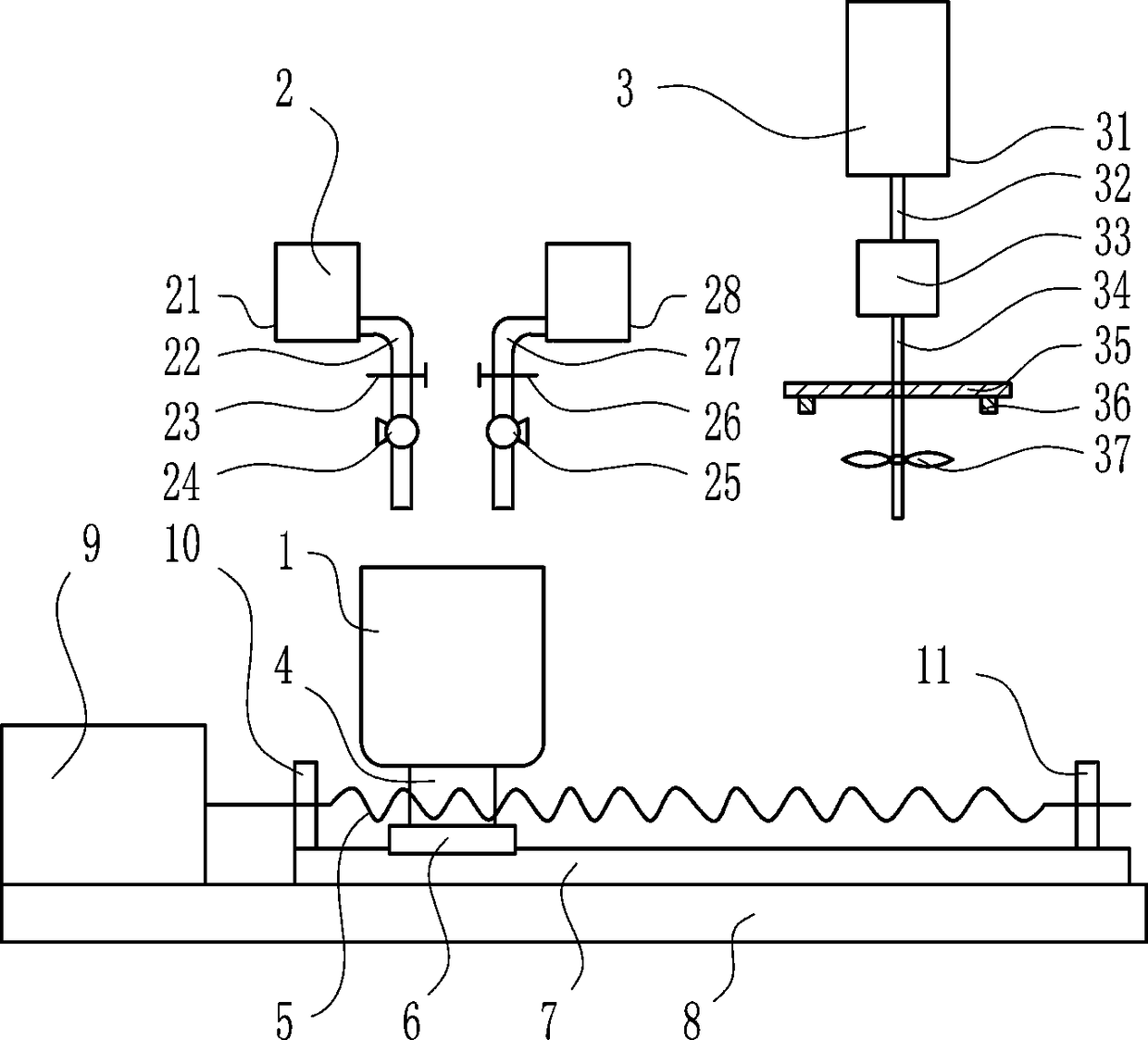

[0028] A mixed homogeneous co-precipitation device for rare earth ore precipitation, such as Figure 1-4 As shown, it includes a sedimentation tank 1, a material-liquid conveying device 2, a mixing and stirring device 3, a nut 4, a screw rod 5, a slider 6, a slide rail 7, a base 8, a motor I 9, a left bearing 10 and a right bearing 11; A material-liquid conveying device 2 is provided above the sedimentation tank 1, and a mixing and stirring device 3 is provided on the right side of the material-liquid conveying device 2. The mixing and agitating device 3 is provided above the sedimentation tank 1, and a nut is provided below the sedimentation tank 1. 4. The nut 4 is fixedly connected with the sedimentation tank 1, the nut 4 is arranged on the screw rod 5, the nut 4 is matched with the screw rod 5, the nut 4 and the screw rod 5 are arranged in a movable connection, and a sliding plate is arranged under the nut 4 Block 6, the sliding block 6 and the nut 4 are arranged in a fixed ...

Embodiment 2

[0030] A mixed homogeneous co-precipitation device for rare earth ore precipitation, such as Figure 1-4 As shown, it includes a sedimentation tank 1, a material-liquid conveying device 2, a mixing and stirring device 3, a nut 4, a screw rod 5, a slider 6, a slide rail 7, a base 8, a motor I 9, a left bearing 10 and a right bearing 11; A material-liquid conveying device 2 is provided above the sedimentation tank 1, and a mixing and stirring device 3 is provided on the right side of the material-liquid conveying device 2. The mixing and agitating device 3 is provided above the sedimentation tank 1, and a nut is provided below the sedimentation tank 1. 4. The nut 4 is fixedly connected with the sedimentation tank 1, the nut 4 is arranged on the screw rod 5, the nut 4 is matched with the screw rod 5, the nut 4 and the screw rod 5 are arranged in a movable connection, and a sliding plate is arranged under the nut 4 Block 6, the sliding block 6 and the nut 4 are arranged in a fixed ...

Embodiment 3

[0033] A mixed homogeneous co-precipitation device for rare earth ore precipitation, such as Figure 1-4 As shown, it includes a sedimentation tank 1, a material-liquid conveying device 2, a mixing and stirring device 3, a nut 4, a screw rod 5, a slider 6, a slide rail 7, a base 8, a motor I 9, a left bearing 10 and a right bearing 11; A material-liquid conveying device 2 is provided above the sedimentation tank 1, and a mixing and stirring device 3 is provided on the right side of the material-liquid conveying device 2. The mixing and agitating device 3 is provided above the sedimentation tank 1, and a nut is provided below the sedimentation tank 1. 4. The nut 4 is fixedly connected with the sedimentation tank 1, the nut 4 is arranged on the screw rod 5, the nut 4 is matched with the screw rod 5, the nut 4 and the screw rod 5 are arranged in a movable connection, and a sliding plate is arranged under the nut 4 Block 6, the sliding block 6 and the nut 4 are arranged in a fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com