Device for varying valve timing in an internal combustion engine

一种控制时间、内燃机的技术,应用在阀装置、传动装置、机械设备等方向,能够解决加速噪音产生、加大等问题,达到紧凑结构形式的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

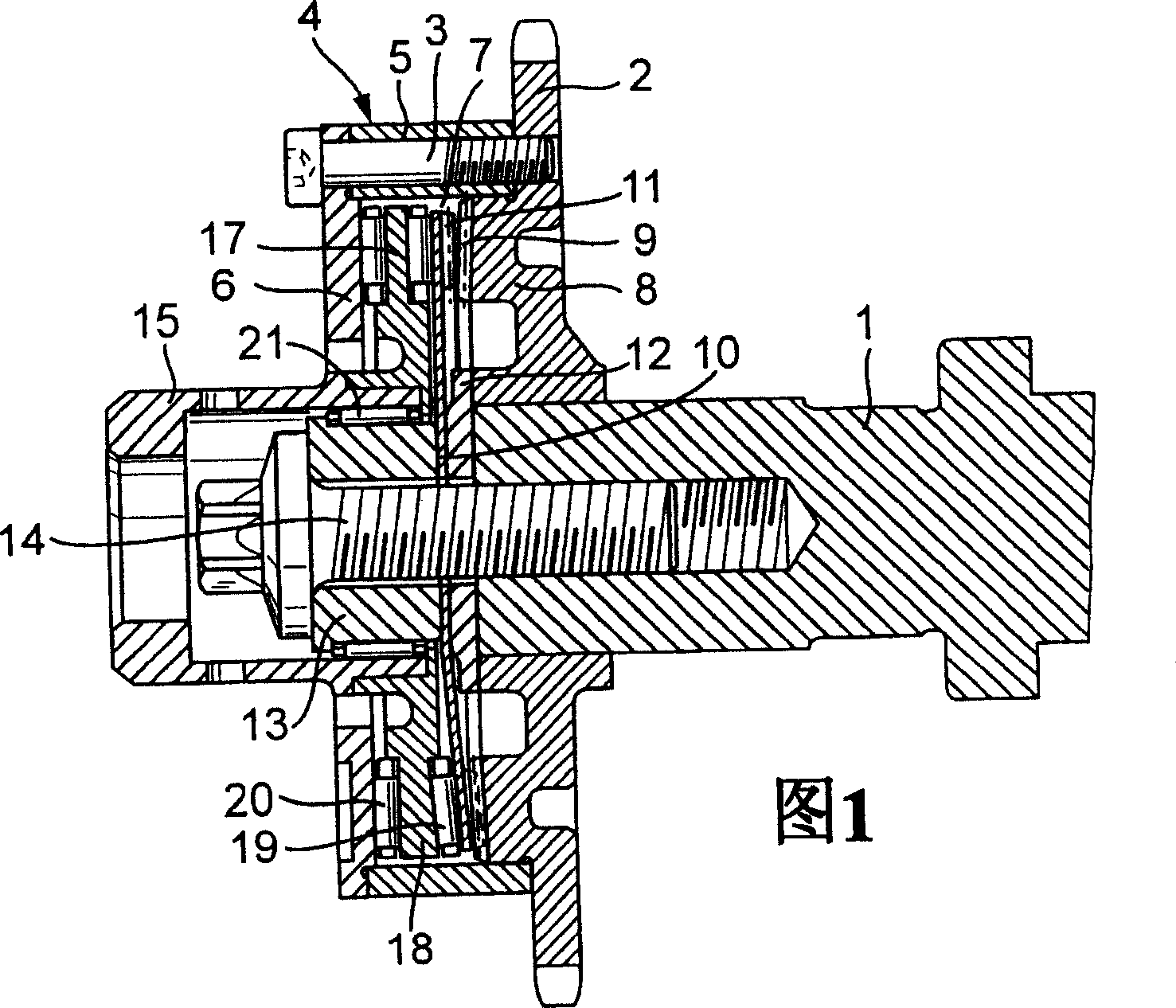

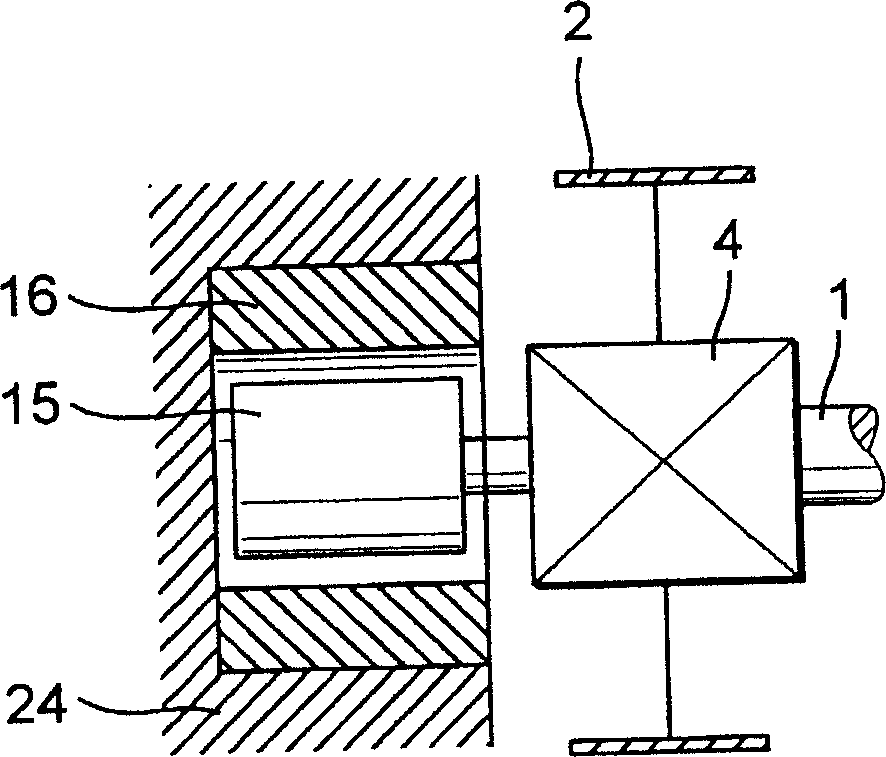

[0019] In FIG. 1 , the end section of the camshaft of the internal combustion engine is denoted by 1 , on which a drive wheel 2 , which is designed as a sprocket, is rotatably mounted. The drive wheel 2 is driven from a not shown driven wheel of a camshaft of the internal combustion engine via a chain, also not shown. It goes without saying that instead of a chain a toothed belt drive or a toothed drive can also be provided, wherein then there are corresponding drive wheels which match the pitch of the toothed belt. The housing 4 is clamped by means of the driving wheel 2 via the fastening screws 3 and consists of an annular housing part 5 and a disk-shaped housing wall 6 . The driving wheel 2 , the annular housing part 5 and the disk-shaped housing wall 6 together form the inner chamber 7 of the housing 4 .

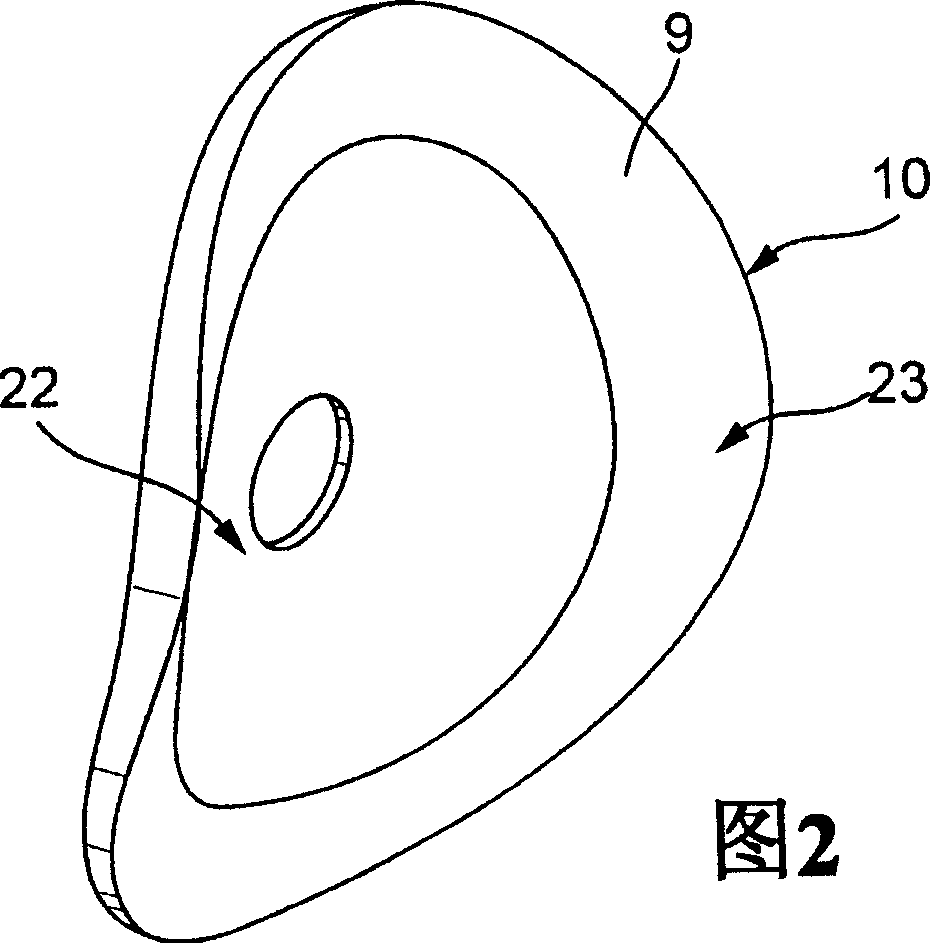

[0020] Drive wheel 2 has, on its end face close to interior space 7 , a section serving as adjustment element 8 , which has a first end face engagement 9 . A disc 10 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com