A fluid-dispensing circuit with check valves

A technology of one-way valve and circuit, which is applied in the direction of distribution device, liquid distribution, conveying or transfer device, special distribution device, etc. It can solve the problems of product flow pressure reduction, valve can not be sealed, system accuracy reduction, etc., to achieve convenient Effect of complete filling, improved conveying accuracy, and reduced risk of cavitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

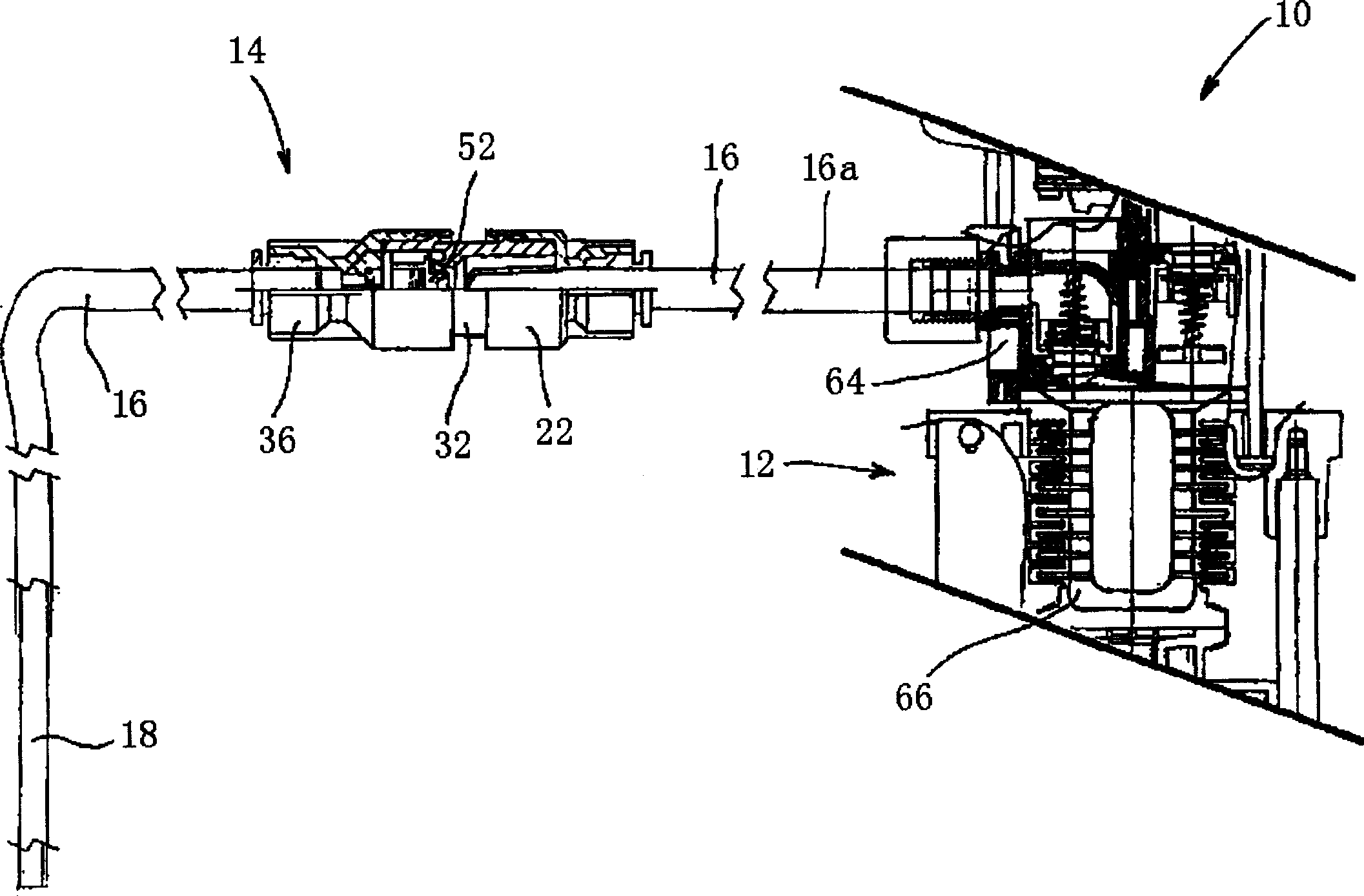

[0020] now refer to figure 1 , the distribution circuit 10 includes: a pump 12 with a variable volume chamber, such as a bellows pump or a diaphragm pump; a one-way delivery valve 14 mounted on the outside of the pump 12 and placed at the nozzle extending from the pump 12 18 in the delivery pipe 16.

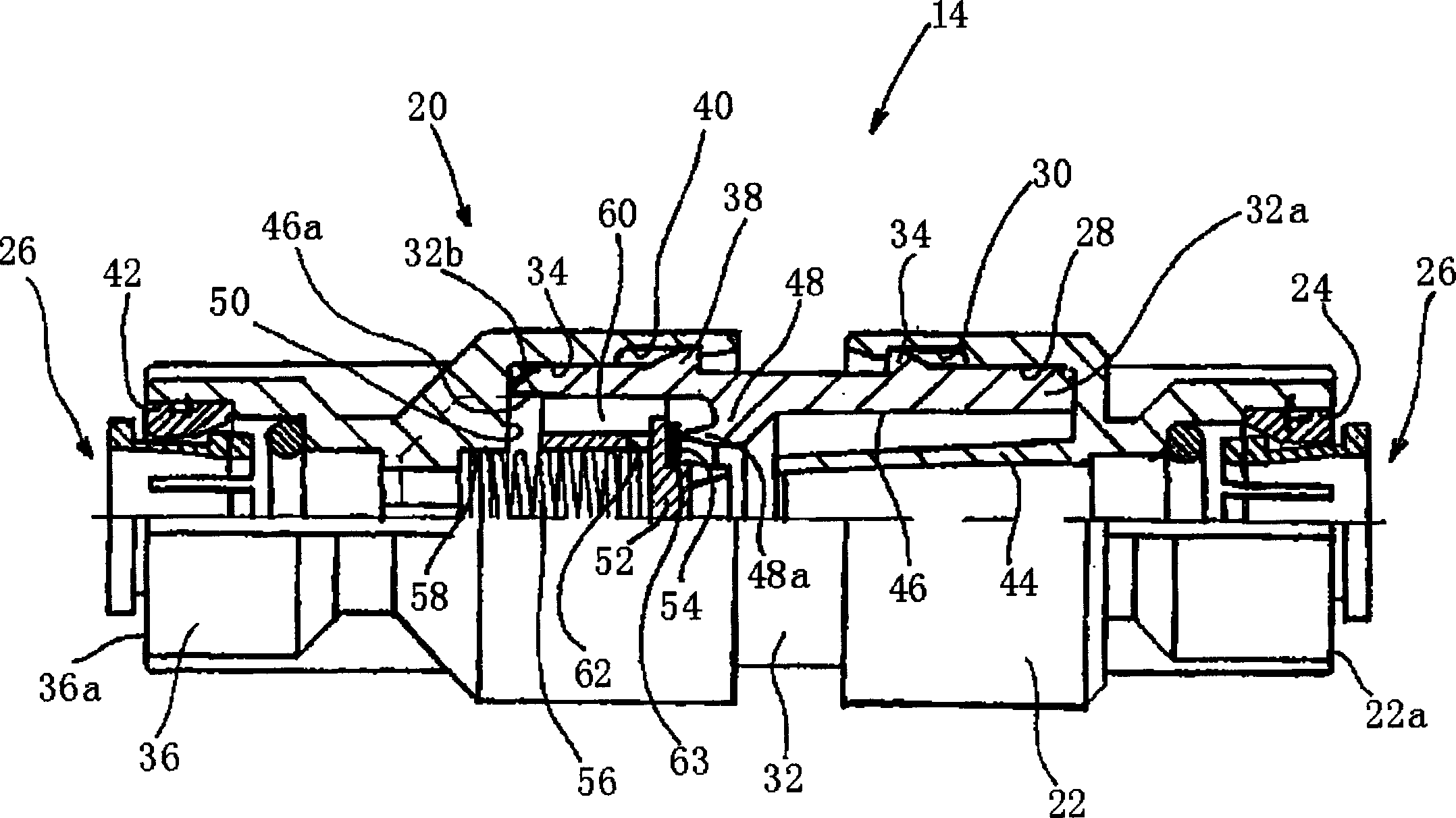

[0021] Transfer valve 14 establishes shell 20 (see figure 2 ), preferably but not limited to, including three hollow parts that can fit into each other. figure 2 In the illustrated embodiment, one end 22a of the inlet member 22 is provided with a sleeve 24 for insertion of a quick-fit tubing connection 26 of known type. The other end of the inlet part 22 has a hole 28 which is, preferably but not limited to, cylindrical and has an annular groove 30 on its side wall. One end 32 a of the guide member 32 is substantially cylindrical so that it can be inserted into the hole 28 , it is preferably but not limited to this shape, and a preferably annular tooth 34 is provided on its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com