Fluorine containing optical plastic perform-rod with gradient refractive index, preparing process and usage thereof

A gradient refractive index and preform technology, which is applied in the field of fluorine-containing gradient refractive index optical plastic preforms, can solve the problems of low working temperature, high cost, and reduced polymer stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

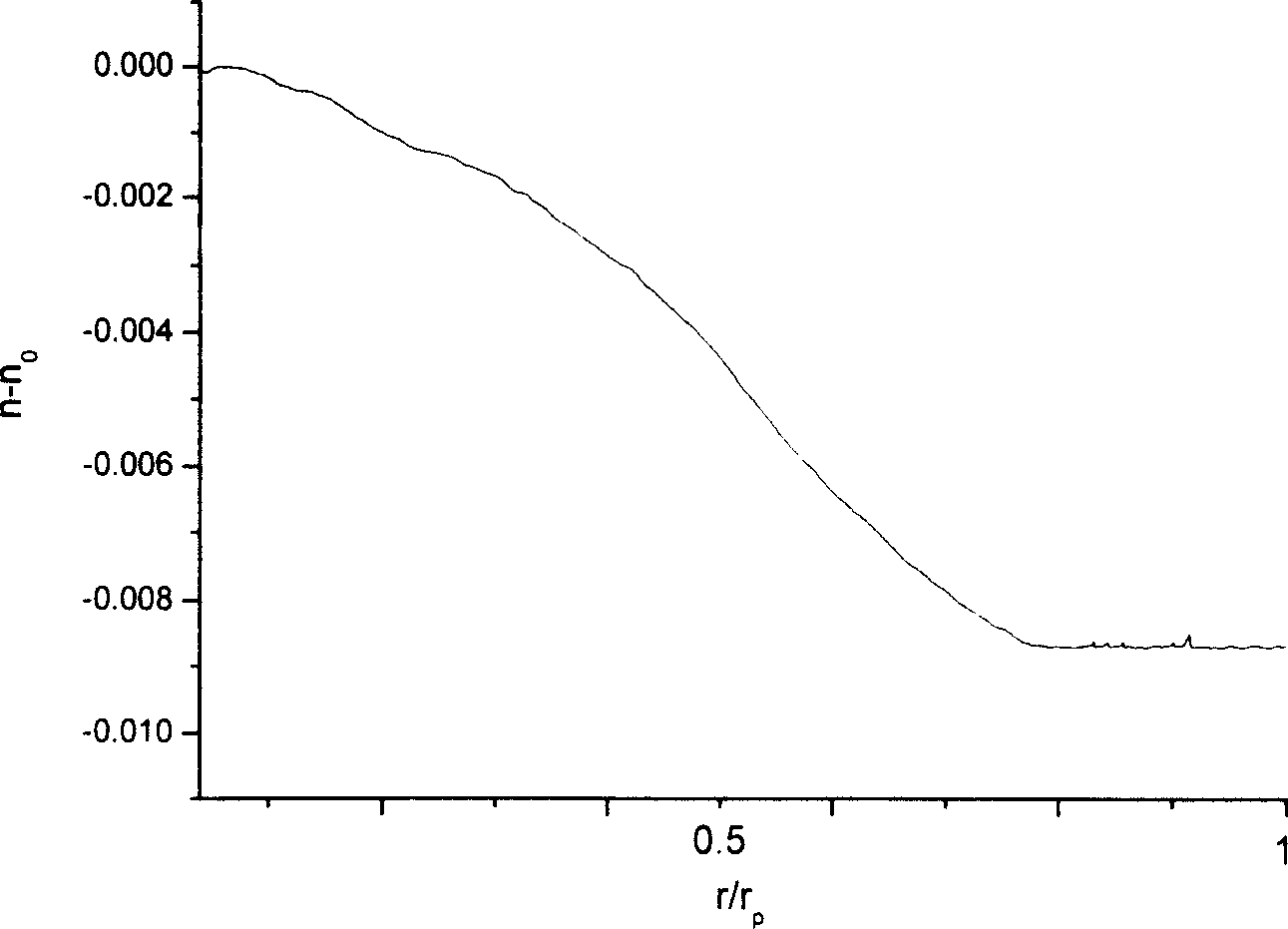

[0029] Add 4 grams of hexafluorobutyl methacrylate containing 0.3% AIBN into a sealed tube with a length of about 15 cm and a diameter of 14 mm. Freeze-drying, evacuation, and nitrogen filling were repeated three times to seal the sealed tube. The sealed tube was placed horizontally and rotated, and reacted at 60°C for 72 hours. A polymerized hollow tube is obtained. The spout was cut and 12 grams of a solution of 0.3% BPO and 5% benzyl benzoate in hexafluorobutyl methacrylate was added. Stand vertically for 2 hours, heat up to 60°C, cool to room temperature after 1 hour, then react at 60°C for 72 hours, and continue to react at 80°C and 100°C for 24 hours each. After the reaction is finished, it is cooled in a refrigerator, and the outer glass is removed to obtain a transparent preform. The refractive index of the fluorine-containing gradient index optical plastic preform of the preform is as follows figure 1 As shown,.

Embodiment 2

[0031] Add 8 g of tetrafluoropropyl methacrylate containing 0.3% AIBN to a sealed tube with a length of 15 cm and a diameter of 14 mm to freeze-dry, vacuumize and fill with nitrogen three times to seal the tube. The sealed tube was placed horizontally and centrifuged, and reacted at 67°C for 48 hours. A polymerized hollow tube is obtained. The nozzle of the tube was cut and 8 g of tetrafluoropropyl methacrylate solution containing 0.3% BPO and 8% bromobenzene was added. Stand vertically for 1 hour, heat up to 60°C, cool to room temperature after 1 hour, then continue to react at 67°C for 72 hours, and continue to react at 80°C and 100°C for 48 hours respectively. After the reaction is finished, it is cooled in a refrigerator, and the outer glass is removed to obtain a transparent preform.

Embodiment 3

[0033] Add 96 grams of trifluoroethyl methacrylate containing 0.3% BPO into a sealed tube with a length of 60 cm and a diameter of 28 mm to freeze-dry, vacuumize and fill with nitrogen three times to seal the tube. The sealed tube was placed horizontally in a high-speed centrifuge, and reacted at 65°C for 72 hours. A polymerized hollow tube is obtained. The nozzle was cut open and 36 grams of a solution of 0.3% BPO and 10% biphenyl in tetrafluoropropyl methacrylate was added. Stand vertically for 0.5 hours, raise the temperature to 60°C, cool to room temperature after 1 hour, then continue to react at 67°C for 55 hours, and continue to react at 80°C and 100°C for 24 hours each. After the reaction is finished, it is cooled in a refrigerator, and the outer glass is removed to obtain a transparent preform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com