Process and apparatus for multilayer toilet paper forming

A molding process and molding device technology, applied to paper, papermaking, paper machines, etc., can solve problems such as poor anti-lint resistance, complex molding process and equipment, and achieve the effect of meeting environmental protection requirements, simple structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

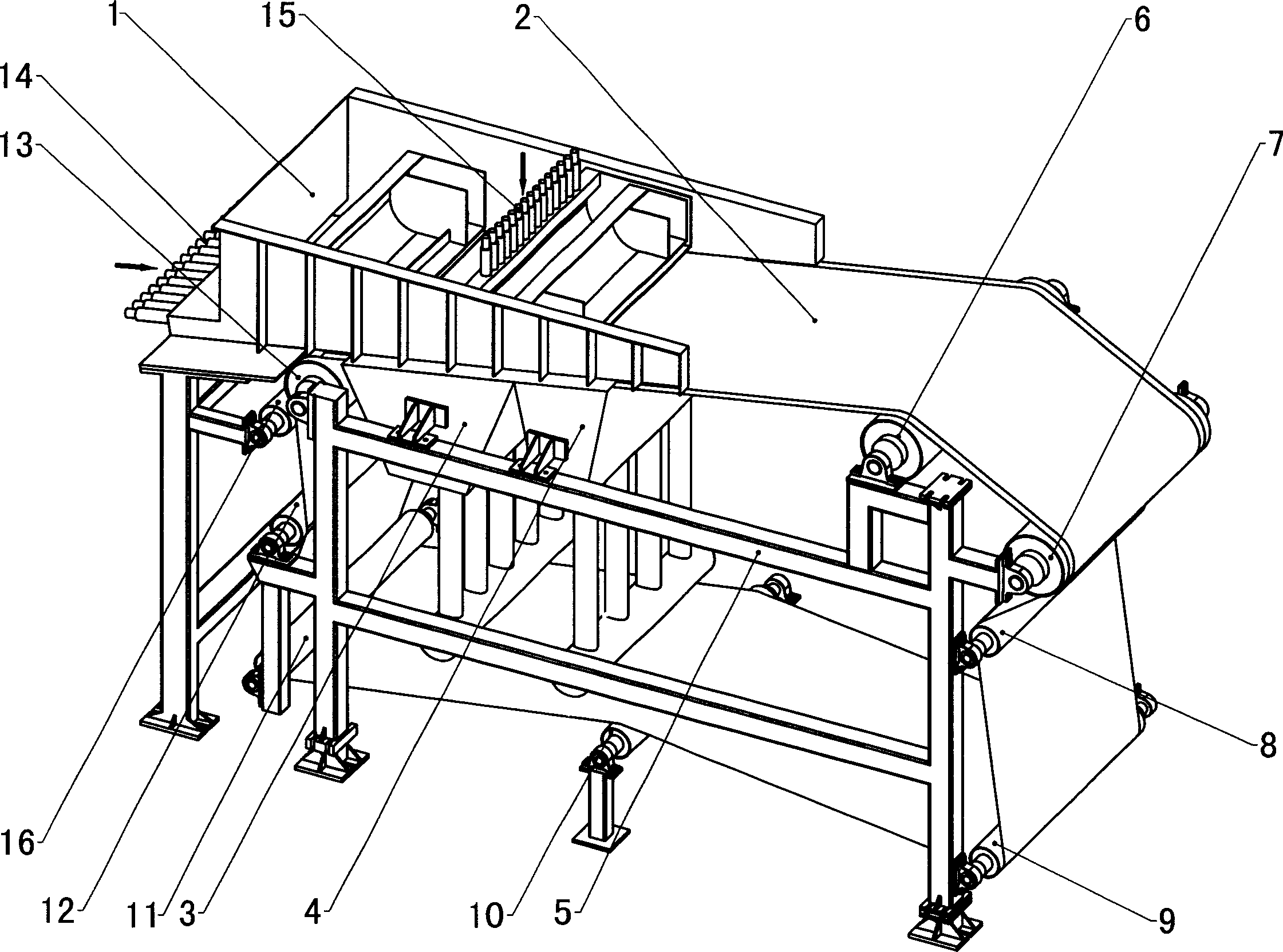

[0018] Example 1: Double-layer toilet paper forming device

[0019] refer to figure 1 , the present embodiment 1 is made up of headbox 1, transfer filter screen 2, wind power dehydration box 3,4, and transfer filter screen 2 is made up of roller 6,7,8,9,10,11, 12, 13, 16 transmission connections, the headbox 1 is connected to the first layer of wood pulp nozzles 14 and the second layer of wood pulp nozzles 15, the bottom of the headbox is at an inclination angle of 5 to 30 degrees from the horizontal, and the transfer filter screen 2 and the headbox The bottom is matched, and the air dewatering boxes 3 and 4 are arranged on the lower end of the transfer screen 2 corresponding to the headbox 1. The first layer of wood pulp nozzles 14 connected to the headbox are arranged upwards in the same direction as the bottom of the headbox, and the second layer of wood pulp nozzles 15 connected to the headbox are arranged vertically downward.

Embodiment 2

[0020] Embodiment 2: double-layer toilet paper molding process

[0021] 1) The bottom of the headbox is arranged at an inclination angle of 5 to 30 degrees;

[0022] 2) On the transmission screen with an inclination angle of 5 to 30 degrees brought by the drive roller, spray the first layer of long-fiber wood pulp that accounts for 20% of the total amount and the second layer of short-fiber wood pulp that accounts for 80% of the total amount. Wood pulp; long-fiber wood pulp is all prepared by adding water to commercially available long-fiber commercial wood pulp, and all short-fiber wood pulp is prepared by adding water to commercially available short-fiber commercial wood pulp; during the spraying process, the second A layer of short-fiber wood pulp is applied on the first layer of long-fiber wood pulp and filled with each other;

[0023] 3) At the lower end of the transfer screen corresponding to the headbox, two air dehydration boxes, the first stage and the second stage, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com