Polygonal heat bonding composite laser medium and preparation method thereof

A laser medium and thermal bonding technology, which is applied in the optical field, can solve the problems of limiting laser power and beam quality, and achieve the effects of small edge deformation, small temperature rise, and improved beam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

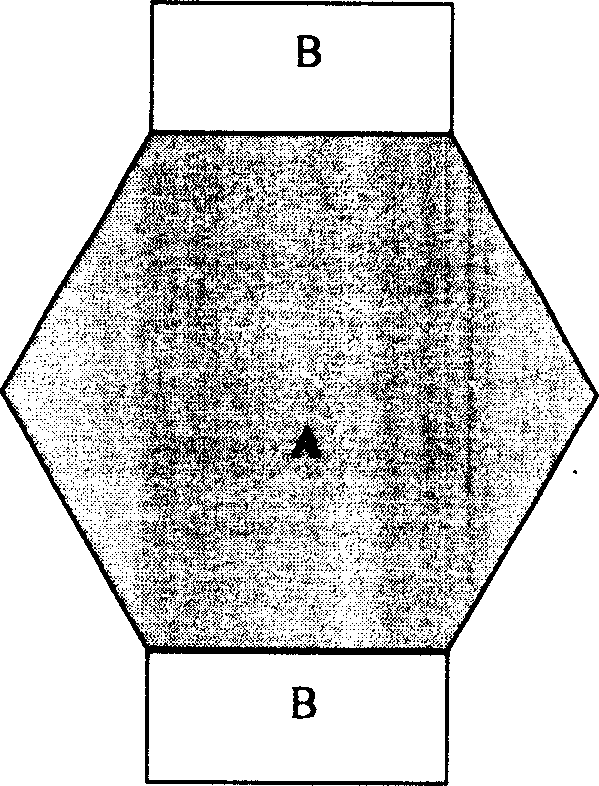

[0027] see figure 1 , figure 2 .

[0028] figure 1 As shown in , there is medium B on the periphery of medium A, and medium A and medium B penetrate into each other through the mutual penetration of molecules to form a seamlessly integrated whole; figure 2 As shown in , three pieces of media B, A, and B form a whole in turn. Described medium A, B are selected from one of following:

[0029] (1) Doped laser crystals, such as Nd:YAG, Cr:YAG, Nd:GGG, Yb:GGG;

[0030] (2), undoped crystals, such as YAG, GGG, GdVO 4 、YVO 4 , KTP;

[0031] (3) Doped laser glass, such as neodymium glass;

[0032] (4) Undoped glass, such as ordinary optical glass.

[0033] Media A and B may be the same or different.

[0034] The preparation method is as follows:

[0035] The bonding planes of media A and B to be bonded are processed flat and smooth, and the smoothness of the bonding planes is above the optical level two, until an ultra-smooth plane; the flatness is zero aperture, that is,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com