Electromagnetic wave absorbing silicon-carbide material coated with barium ferrite film and its preparation process

A barium ferrite, electromagnetic wave absorbing technology, applied in electrical components, other chemical processes, instrument parts, etc., can solve the problems of narrow frequency band, large specific gravity and poor practical effect of ferrite coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

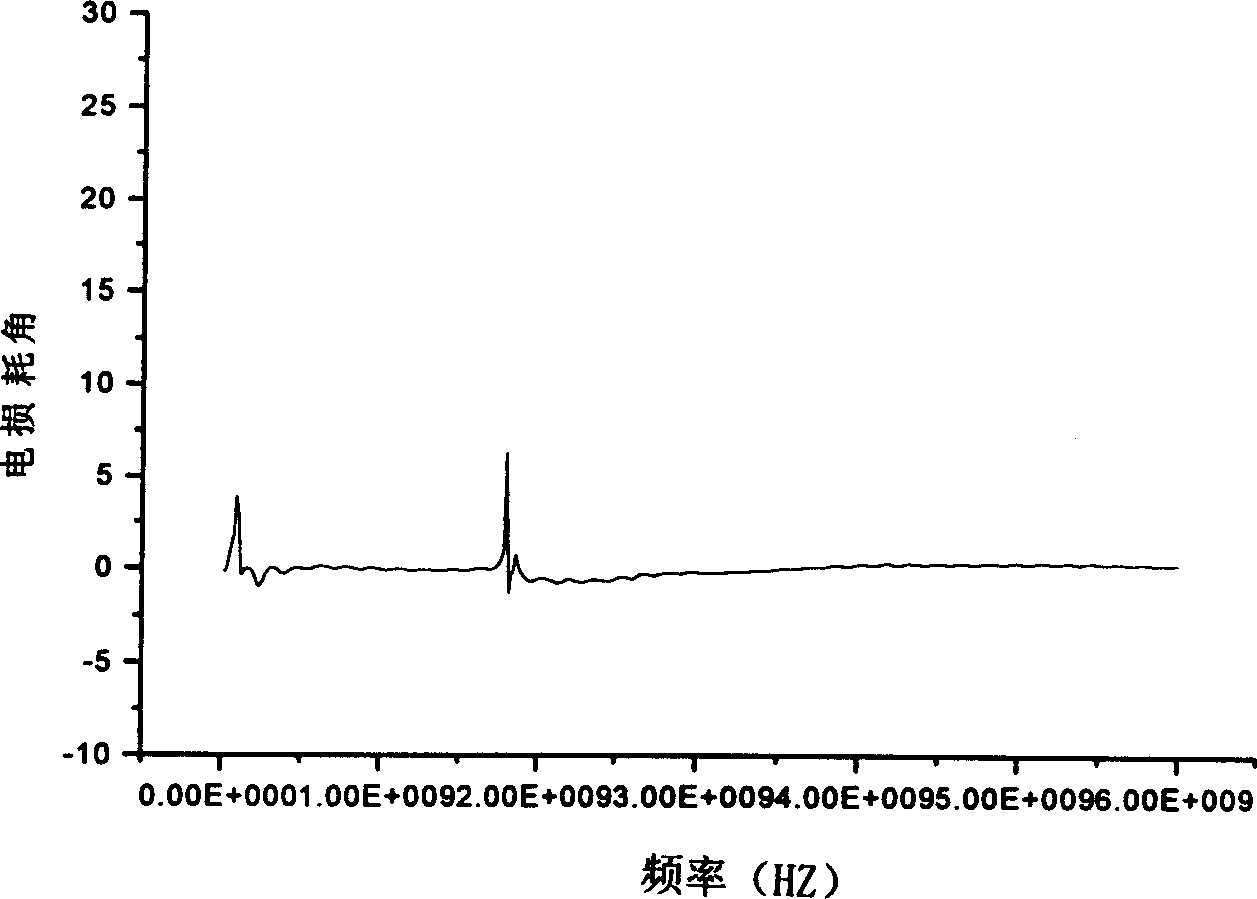

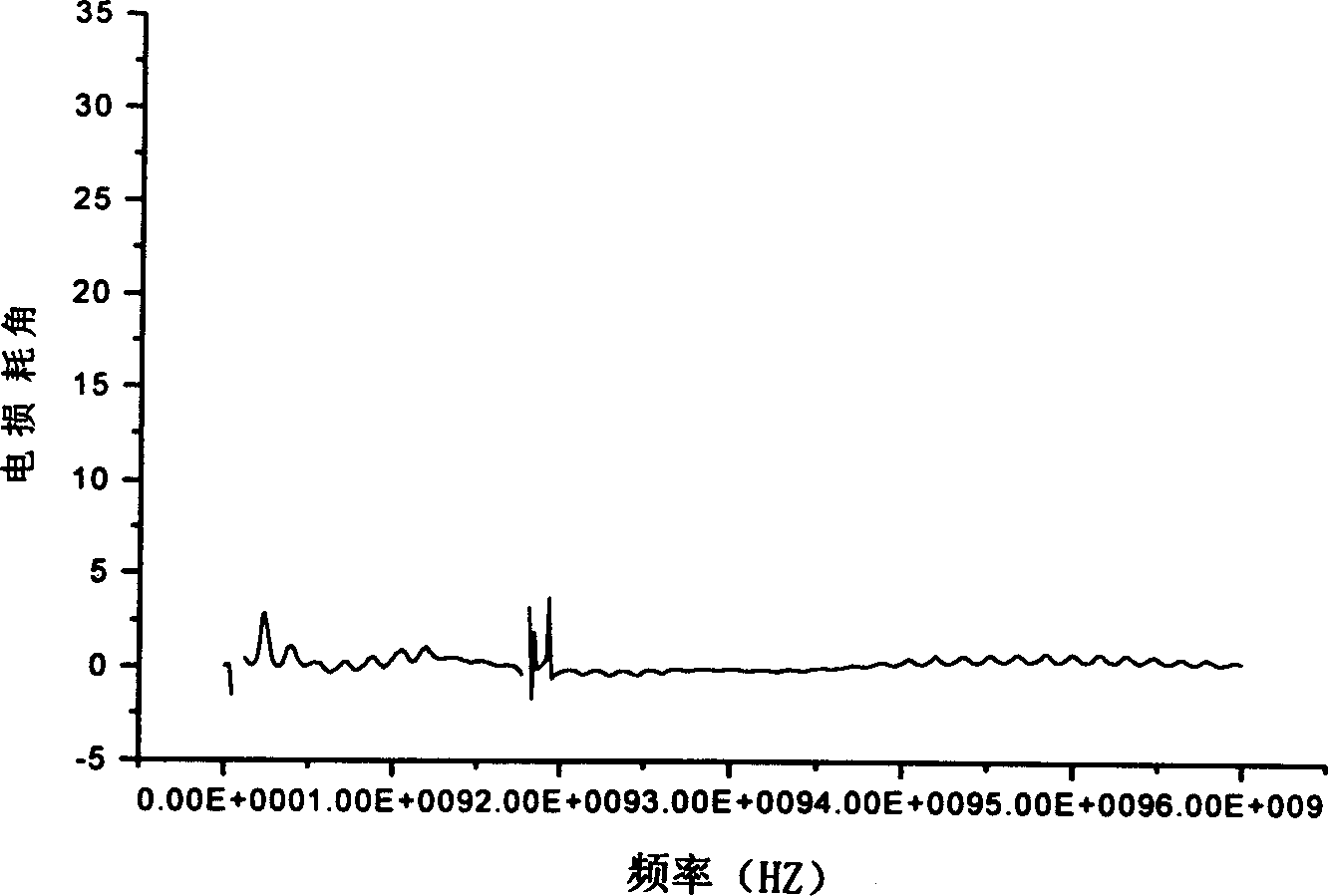

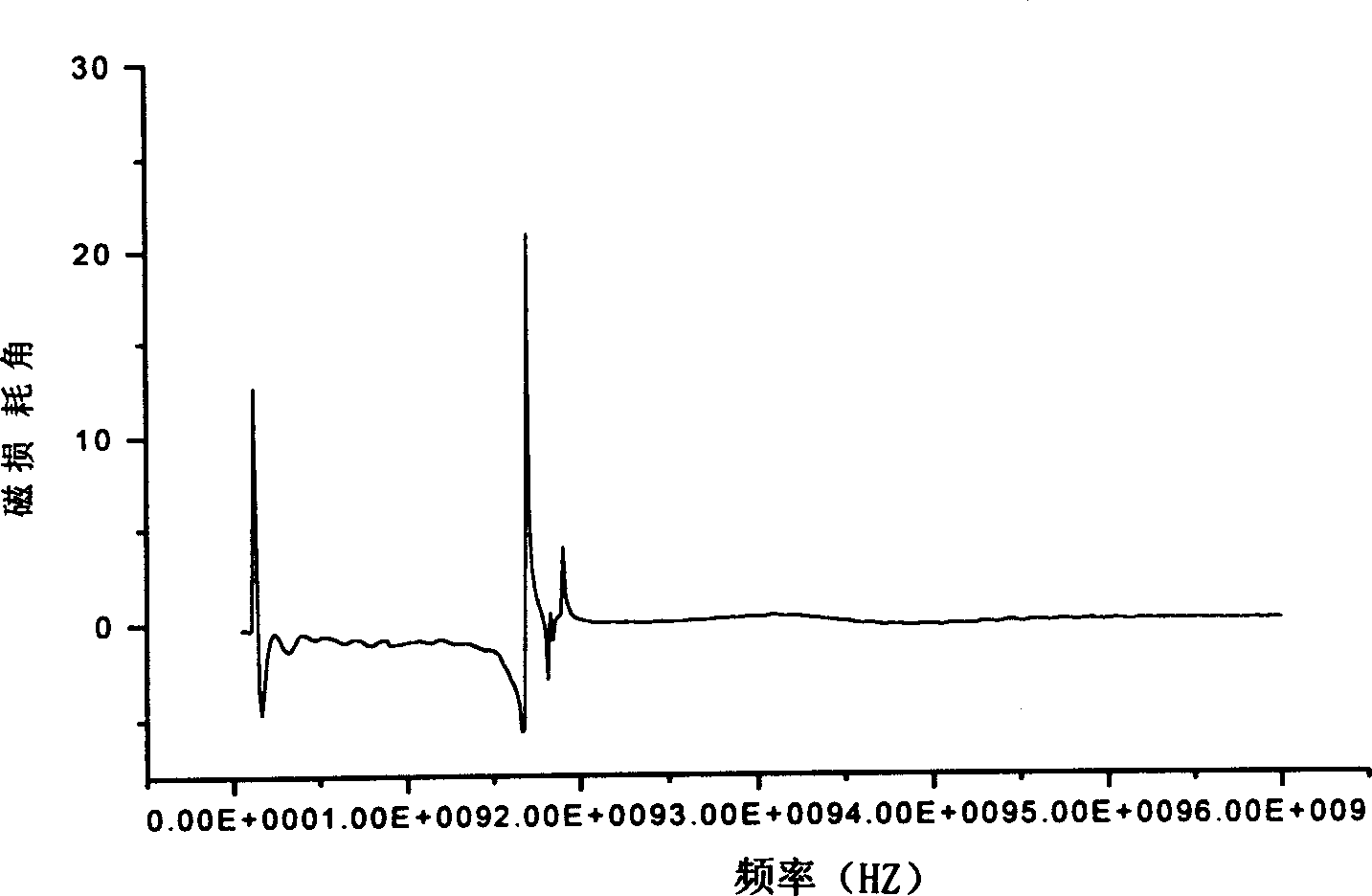

[0025] The precursor was prepared by complexing ferric nitrate and barium nitrate with citric acid. According to the stoichiometric Ba(NO 3 ) 2 : Fe(NO 3 ) 3 : citric acid = 1:12:19 to prepare a solution. Add silicon carbide to the solution. The theoretical product mass ratio of silicon carbide and ferrite is 1:1. Ammonia water was added dropwise to adjust the pH value to 7. The solution was placed in a 90°C water bath and stirred for 4 to 5 hours until the liquid became a viscous colloid. The prepared sol was placed in an oven at 120° C. for 4 h to obtain a dry gel. The resulting gel was heated in a muffle furnace. Heating temperature rise rate: 60°C / h, when the temperature rises to 850°C, keep warm for 1h.

Embodiment 2

[0027] The precursor was prepared by complexing ferric nitrate and barium nitrate with citric acid. According to the stoichiometric Ba(NO 3 ) 2 : Fe(NO 3 ) 3 : citric acid = 1:12:13 to prepare a solution. Add silicon carbide to the solution. The theoretical product mass ratio of silicon carbide and ferrite is 2:1. Ammonia water was added dropwise to adjust the pH value to 7. The solution was placed in a 90°C water bath and stirred for 4 to 5 hours until the liquid became a viscous colloid. The prepared sol was placed in an oven at 120° C. for 5 h to obtain a dry gel. The resulting gel was heated in a muffle furnace. Heating temperature rise rate: 30°C / h, when the temperature rises to 750°C, keep warm for 3h.

Embodiment 3

[0029] The precursor was prepared by complexing ferric nitrate and barium nitrate with citric acid. According to the stoichiometric Ba(NO 3 ) 2 : Fe(NO 3 ) 3 : citric acid = 1:12:15 to prepare a solution. Add silicon carbide to the solution. The theoretical product mass ratio of silicon carbide and ferrite is 1:1.5. Ammonia water was added dropwise to adjust the pH value to 7. The solution was placed in a 90°C water bath and stirred for 4 to 5 hours until the liquid became a viscous colloid. The prepared sol was placed in an oven at 120° C. for 5 h to obtain a dry gel. The resulting gel was heated in a muffle furnace. Heating heating rate: 100°C / h, when the temperature rises to 800°C, keep warm for 2h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com