Automatic shaping method and equipment for load-bearing hollow brick

A technology for automatic forming and load-bearing bricks, applied in the direction of forming indenters, ceramic forming cores, ceramic forming machines, etc., can solve the problems of density and strength, bending resistance not reaching the national standard, unstable brick quality, unreasonable process and other problems , to achieve the effect of liberating labor intensity, simple structure and uniform flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

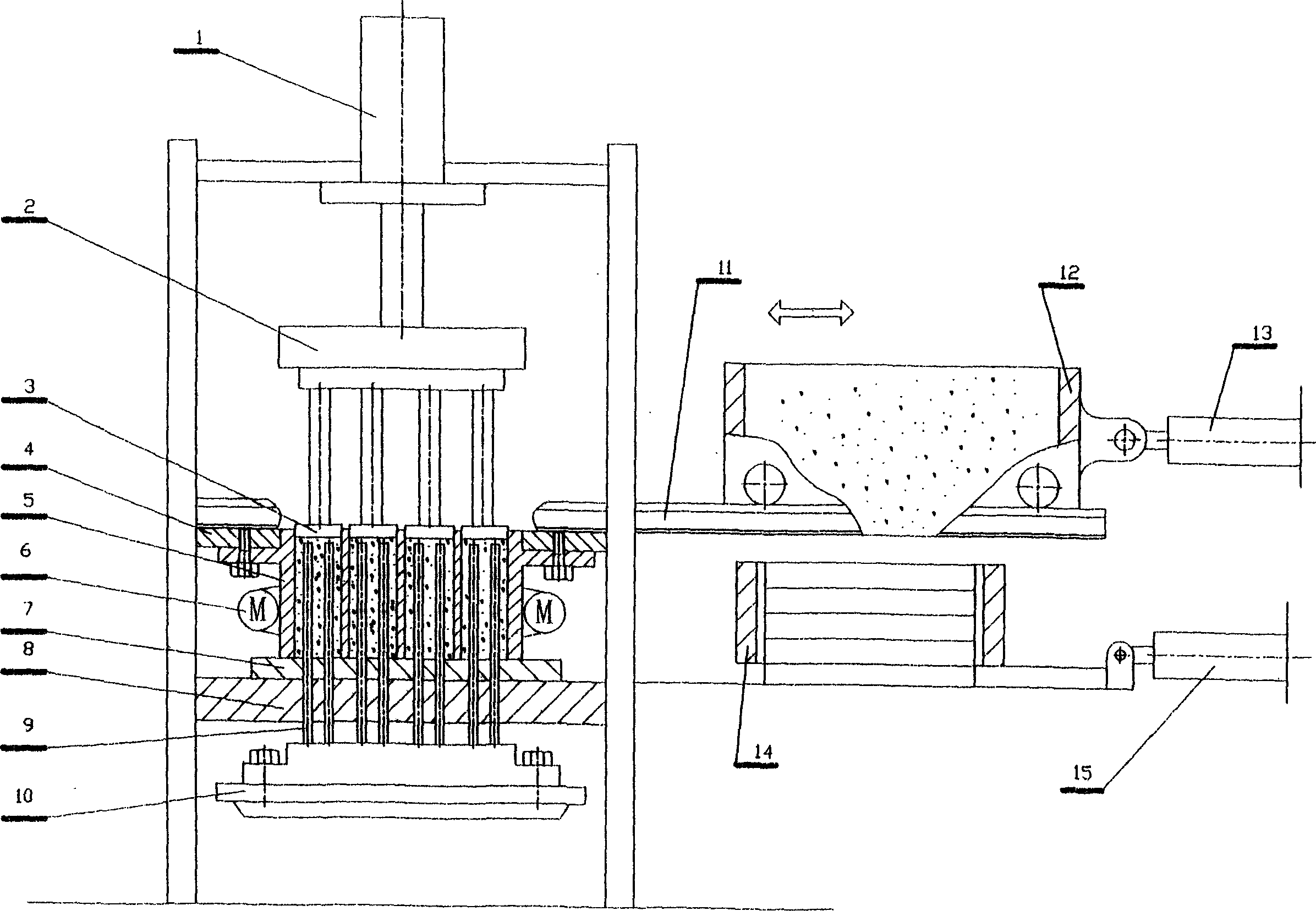

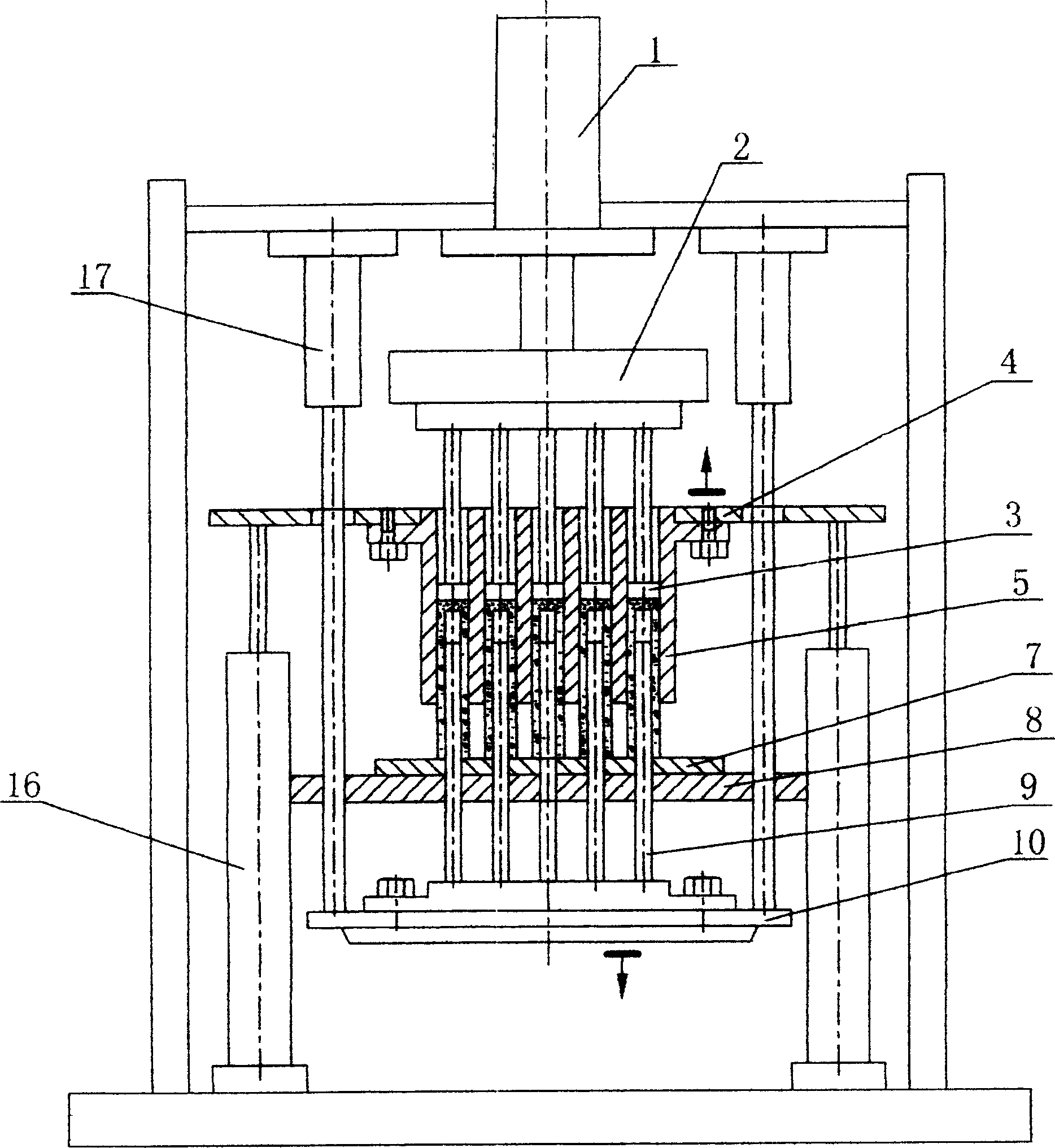

[0021] Such as figure 1 with figure 2 As shown, the hollow load-bearing brick automatic forming equipment includes a forming system and a feeding mechanism. Among them, the forming system consists of 1. Die hydraulic components, 2. Pressure plate, 3. Pressure head, 4. Mold box frame, 5. Mold box, 6. Vibrator, 9. Mold core, 10. Mold core frame, 16. It is composed of hydraulic components for entering (detaching) the mold; the transmission system is mainly composed of 7. Pallet, 8. Workbench, 11. Track, 12. Feeding hopper, 13. Feeding hydraulic component, 14. Pallet box, 15. Push plate hydraulic component Components, 16. Advance (extract) mold hydraulic components, 17. Core advance and retreat hydraulic components and other components.

[0022] It can be seen from the drawings that the forming system and the feeding mechanism are realized by the control of the hydraulic system. The forming system is mainly the whole process of forming the slurry from the pouring box to the bri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com