Starter for a line start electric motor

A technology for starting a motor and a linear motor, applied in the field of a linear starting motor and controlling the above-mentioned starting device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

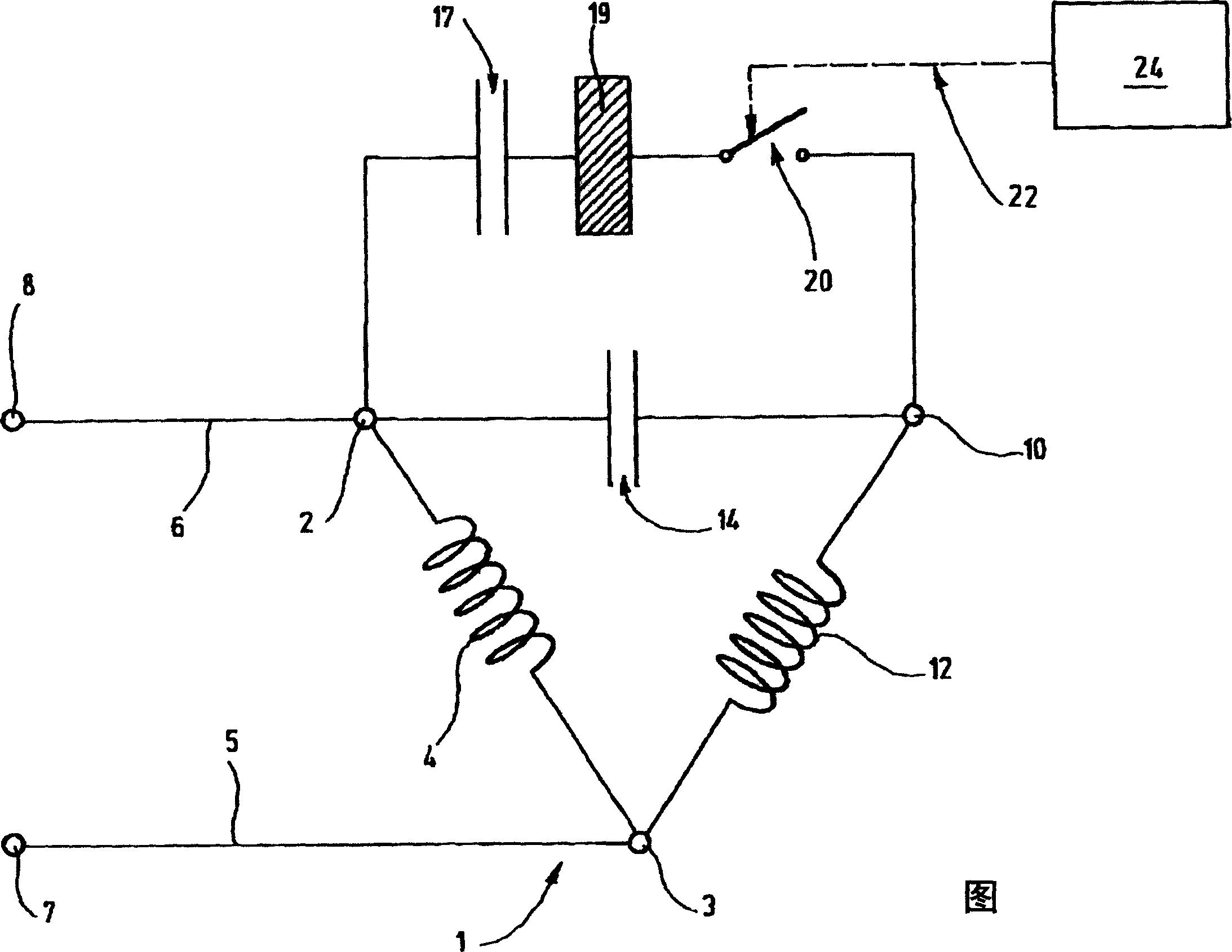

[0022] The drawing shows an electrical circuit of a linear starter motor 1 according to the invention. The linear starter motor 1 comprises two conductor branches 2 and 3 between which a slip coil 4 , also referred to as the main coil, is arranged. The slip coil 4 is supplied with current via connection lines 5 , 6 connected to contacts 7 , 8 of the power supply. A starting coil 12 is arranged between the conductor branch 3 and the further conductor branch 10 . Conductor branches 2, 3 and 10 are arranged at the top of an equilateral triangle. An operating capacitor 14 is arranged between the conductor branches 2 and 10 .

[0023] Starting from line branch 2 , starting capacitor 17 , PTC resistor 19 and switching device 20 are connected in series. The series connection of a starting capacitor 17 , a PTC resistor 19 and a switching device 20 is connected to the conductor branches 2 and 10 and is thus connected in parallel to the operating capacitor 14 . The dashed line 22 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com