Valve

A technology of valves and discs, applied in the field of switching valves, which can solve the problems of high working pressure thrust, large resistance, and increased difficulty in valve opening and closing, and achieve the effects of small operating torque, reduced rotational torque, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

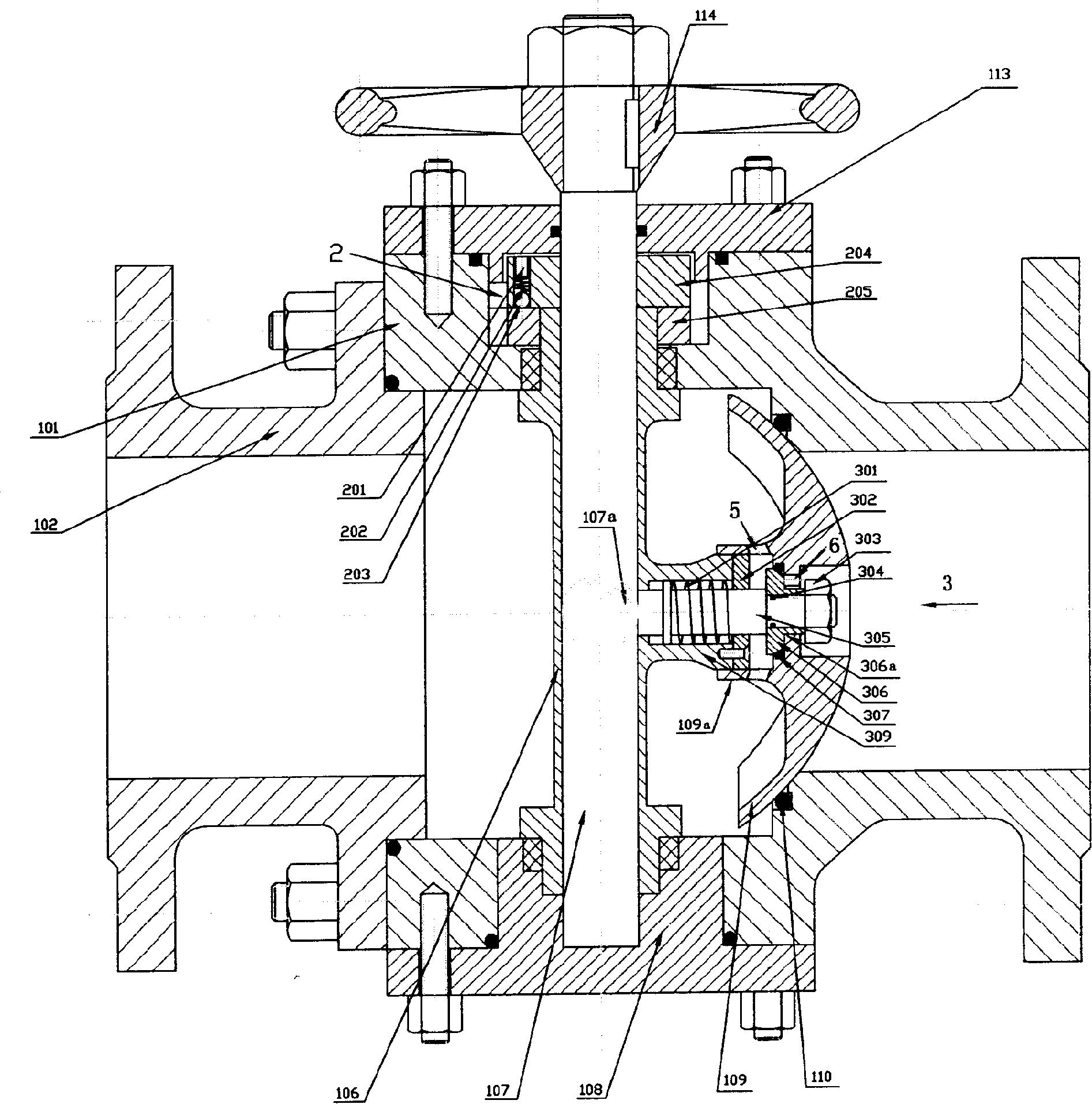

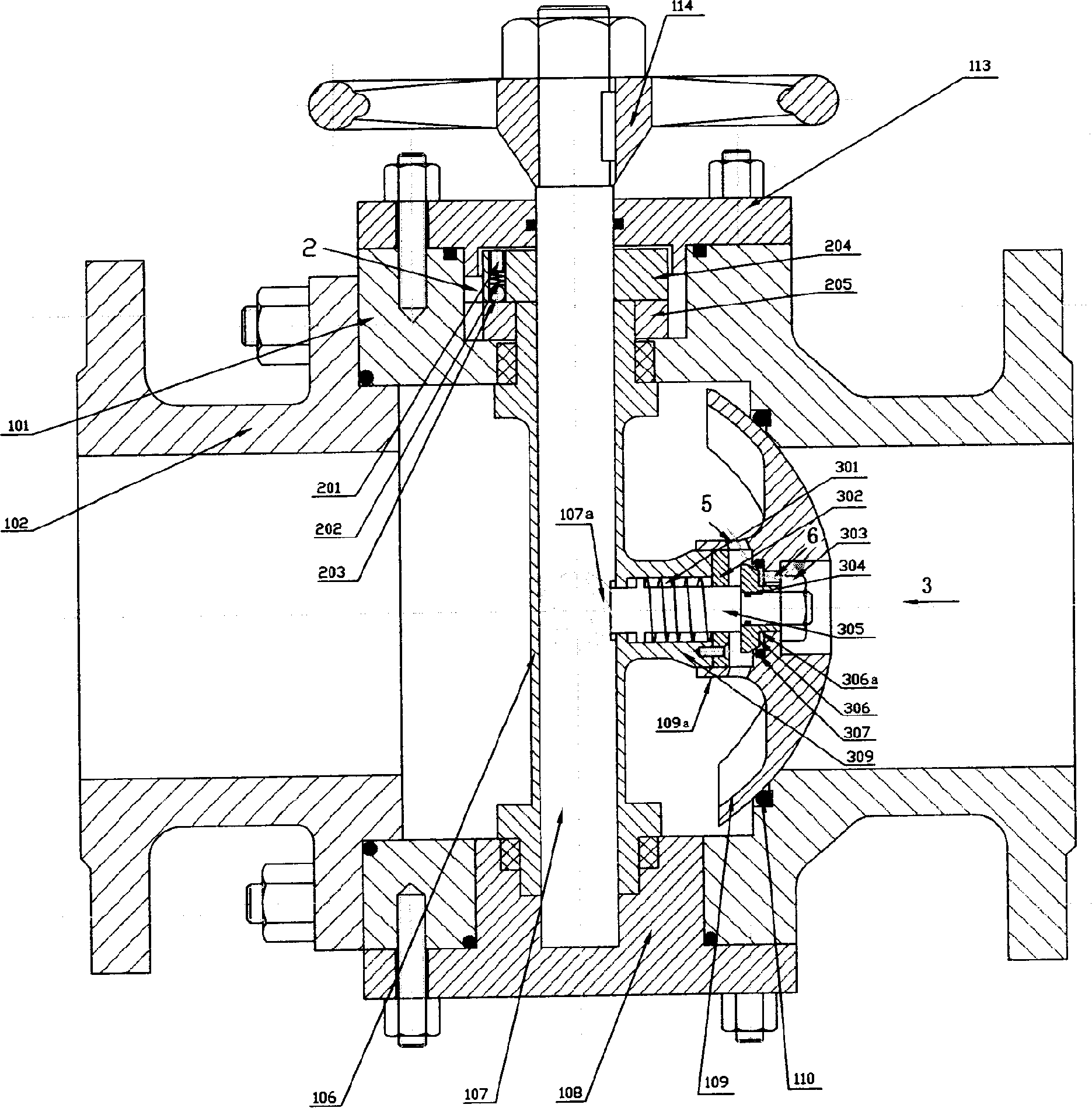

[0018] Such as Figure 1-3 As shown, the valve is mainly composed of a main valve body 101 with upper and lower through holes, a valve disc 109, a valve stem, a handle 114 installed thereon, and an auxiliary mechanism 2. It is characterized in that the valve stem is composed of a drive shaft 107 and The auxiliary driving shaft 106 is composed of a through hole on the auxiliary driving shaft 106, the driving shaft 107 passes through the through hole of the auxiliary driving shaft 106, the valve stem passes through the through hole of the main valve body 101, and an eccentric wheel is arranged on the driving shaft 107 107a (eccentric concave wheel or eccentric cam), a pilot valve body 309 with a through hole is provided on the side of the auxiliary drive shaft 106 corresponding to the eccentric wheel 107a, and a pilot valve body 309 is installed on the pilot valve body 309, so The above-mentioned pilot valve 3 is constituted as follows: the pilot valve rod 305 covered with the s...

Embodiment 2

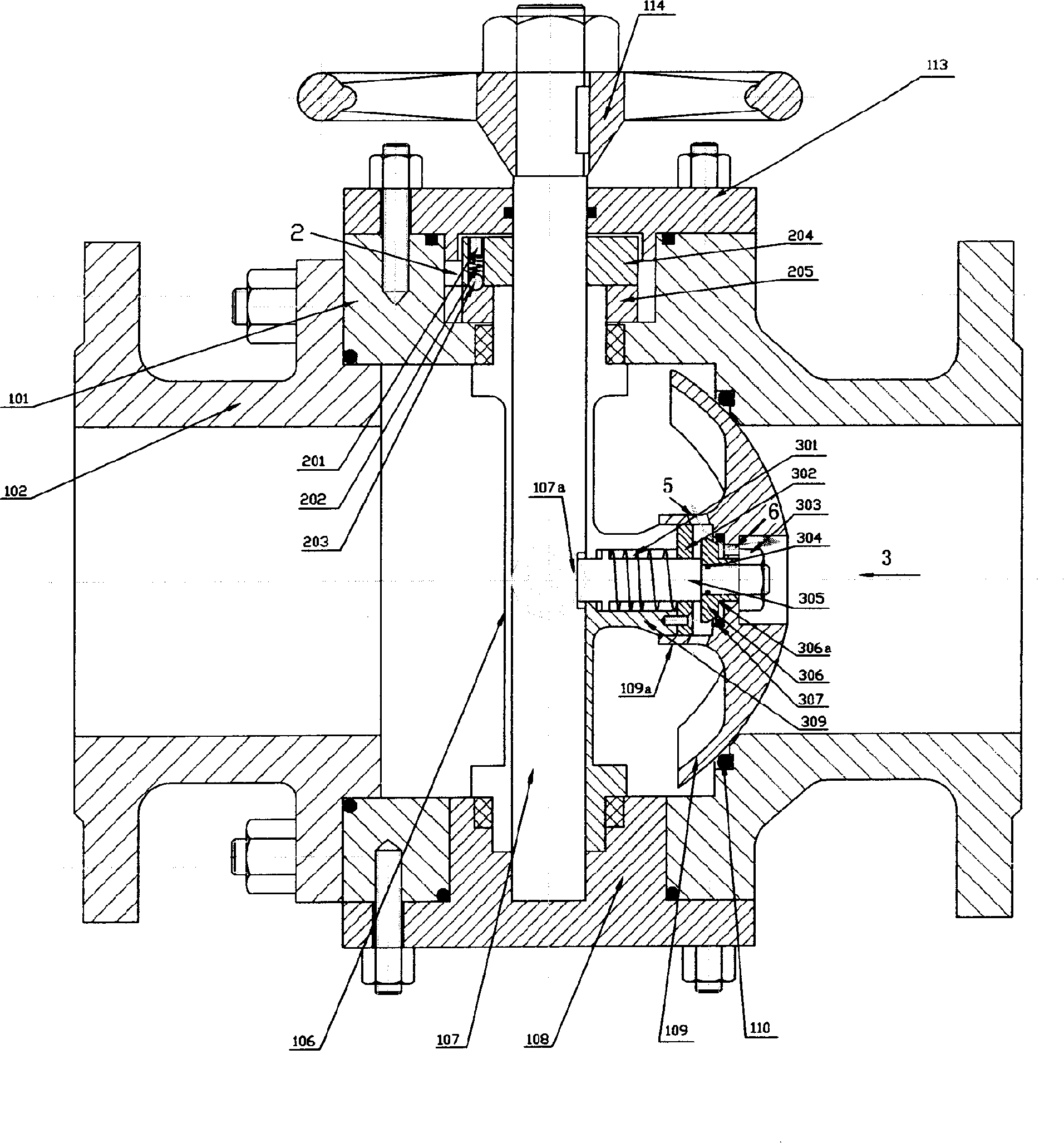

[0024] Such as Figure 4 As shown, the main difference between this valve and Embodiment 1 is: 1) The auxiliary seal composed of the seal 105 and the left valve disc 103, its main function is to reduce pressure and assist sealing when the pilot valve 3 is opened, not It plays the main sealing role. During the assembly process, the gap between the sealing member 105 and the left valve disc 103 can be adjusted so that the sealing member 105 does not contact the left valve disc 104 to form a gap seal; 2) The actuating mechanism 2 It is constituted like this: a small hole is provided on the auxiliary driving shaft 106 of the through hole on the main valve body 101, a driving wheel 204 installed on the driving shaft 107 is arranged above the auxiliary driving shaft 106, and a driving wheel 204 is arranged on the driving wheel 204. There is a threaded hole that is used to install the screw, and the spring 202 is pressed on the steel ball 203 installed on the threaded hole with the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com