Polishing method and device for sphere high quality large area diamond thick film

A diamond thick film, diamond film technology, applied in laser welding equipment, metal processing equipment, welding equipment and other directions, can solve the problems of easy rupture of diamond film, slow polishing rate, fatigue cracking, etc., to achieve uniform polishing, easy operation, damage small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

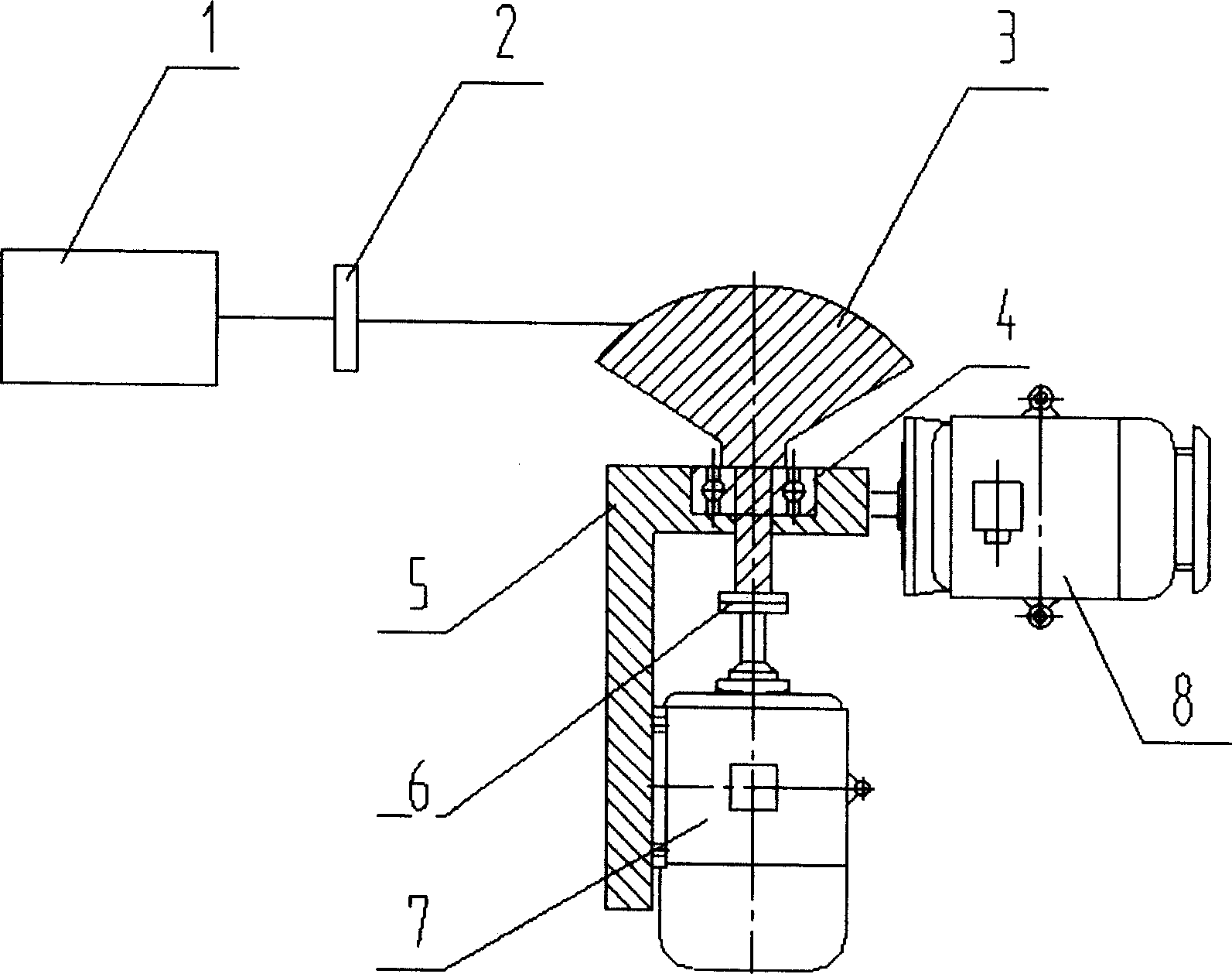

[0018] to combine figure 1 Laser-polished spherical high-quality diamond self-supporting films are illustrated.

[0019] 1. First, polish the growth surface of the diamond film, with the nucleation plane as the reference plane; fix the spherical diamond film with a thickness of 2mm on the arc surface polishing table that can realize three-dimensional movement with 502 glue, the arc surface of the polishing table and the diamond surface arc fit;

[0020] 2. Adjust the focal spot of the Nd:YAG laser to fall on the surface of the diamond film, and adjust the incident angle of the laser to 45°; after adjusting the swing axis to coincide with the center of the arc surface, make the polishing table rotate and swing, and use the Nd:YAG laser energy The density is 8J / cm 2 Carry out rough polishing from time to time, and adjust the height of the polishing table in due course;

[0021] 3. Measure the roughness of the diamond film; when the measured average surface roughness (Ra) is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com