Formingfabric comprising flat shaped conductive monofilamentused in the production of non-woven fabrics

一种无纺布、传导性的技术,应用在纺织、织物、非织造布等方向,能够解决丝网成形扰流等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

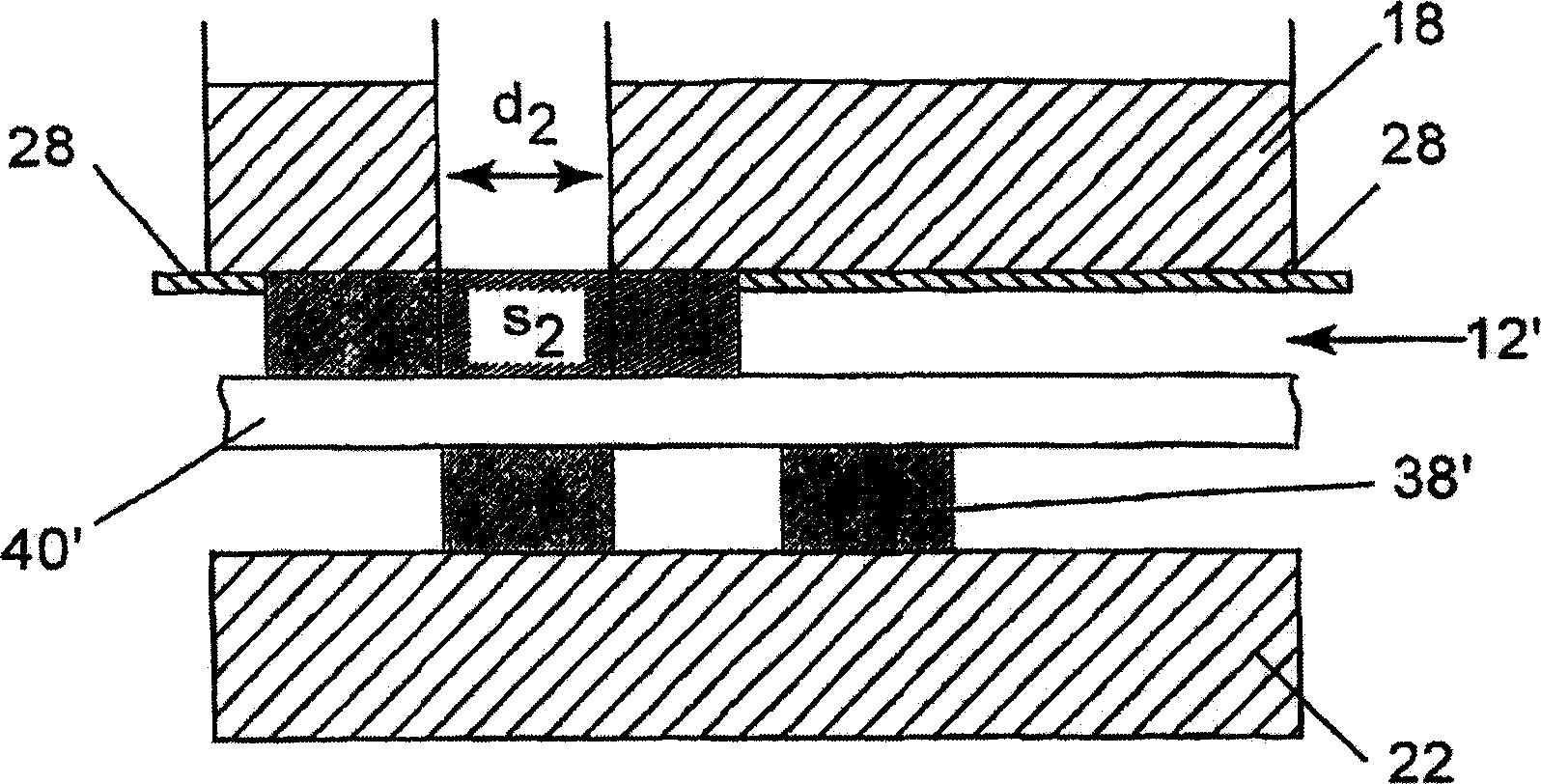

[0021] Referring now more specifically to the drawings in which like elements are similarly numbered, figure 1 Apparatus 10 for making a nonwoven web, member or article is shown. Apparatus 10 is part of a fusion bond forming machine that uses processes other than weaving to make flat or nonwoven webs, components or articles. Nonwoven webs, structures or articles typically consist of fibers or filaments bonded together. Generally, spunbonding involves the extrusion of molten polymer from a spinneret or spinneret, where the molten polymer is processed to form a curtain of strands. An example of such a device is set forth in US Patent Application No. 5,814,349. A large air flow is used to pneumatically stretch, elongate or attenuate the strands which are deposited on the forming fabric 12 after passing through the diffuser and presses are used to apply pressure to the deposit of filaments. As shown, by way of example, there are two presses, a downstream press 14 and an upstrea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com