Sea water hydraulic electric control one-way valve

An electronically controlled one-way valve, seawater technology, used in control valves, valve details, valve devices, etc., can solve problems such as poor sealing performance, heavy weight, and inability to use, and achieve good corrosion resistance, light weight, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

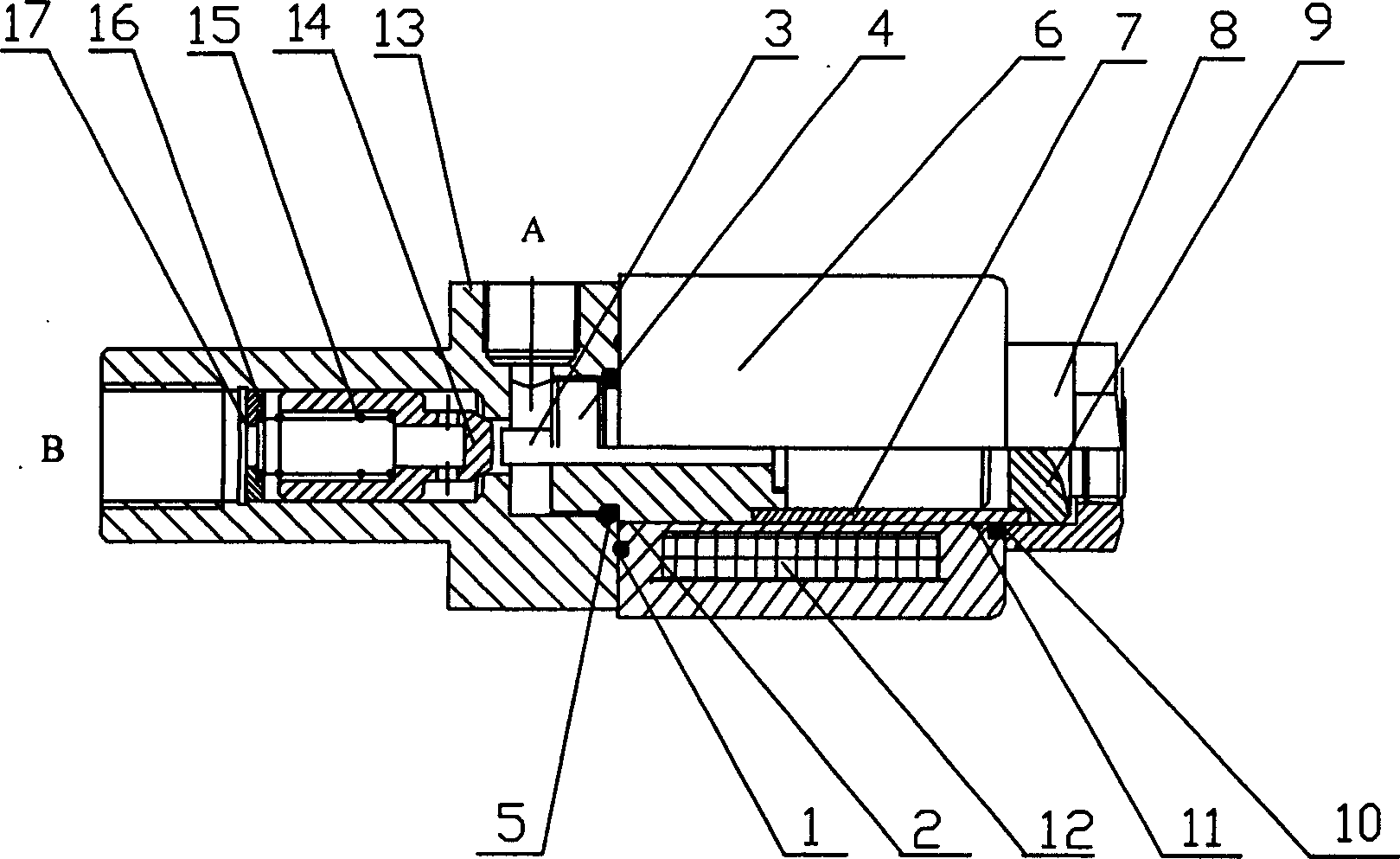

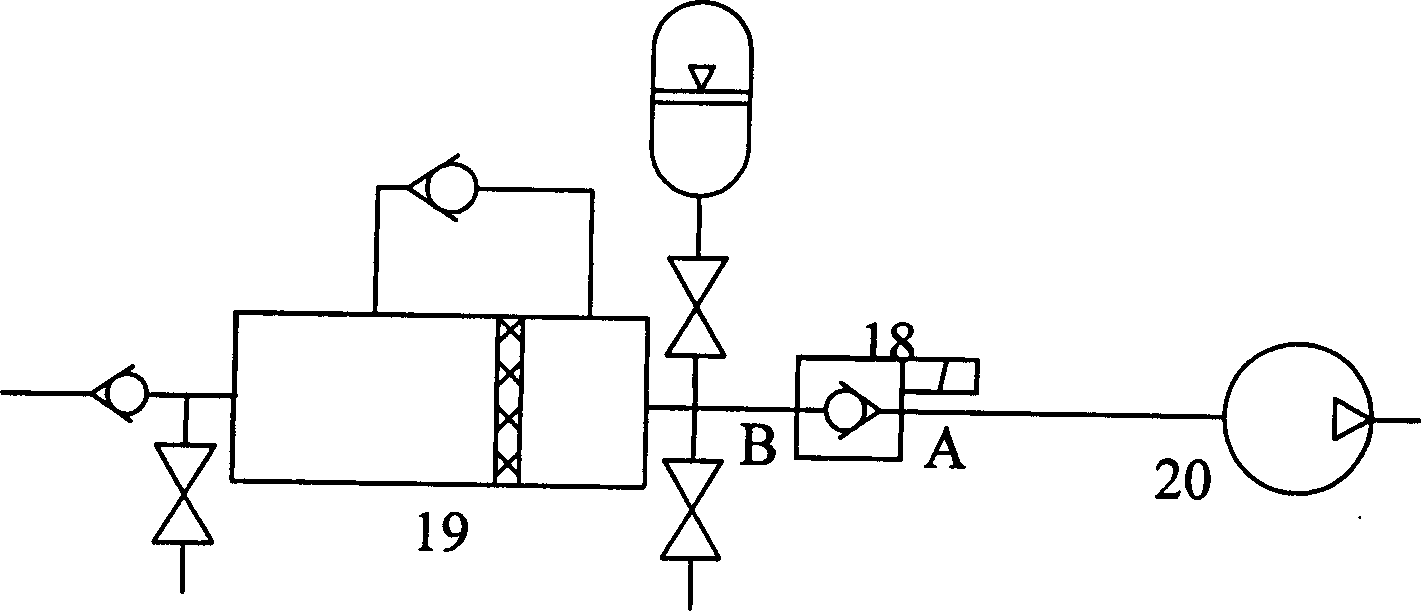

[0021] Such as figure 1 Shown, the present invention comprises and is made up of electromagnet and one-way valve, wherein:

[0022] 1) The electromagnet is a seawater electromagnet: its magnetic core tube assembly includes a perforated end cap 4, a magnetic core tube part 7 and a non-porous end cap 9, one end of the magnetic core tube part 7 is connected with a perforated end cap 4, and the magnetic core tube part The other end of 7 is connected to the non-porous end cap 9; the magnetic core tube assembly is equipped with a stepped armature push rod 3, and after the small end of the armature push rod 3 passes through the end cap 4 with holes, the small end of the armature push rod 3 is exposed Outside the magnetic core tube assembly; the coil assembly includes a coil housing 6 and a coil 12, which are installed outside the magnetic core tube assembly. The end cap nut 8 is threaded with the non-porous end cap 9 and pressed against one side of the coil housing 6. The coil housin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com