A kind of coring device and coring method

A technology of coring device and coring bit is applied in the direction of extracting undisturbed core device, valve device of wellbore/well, earthwork drilling, etc. It can solve problems such as ball valve stuck, and achieve the effect of accurate results and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

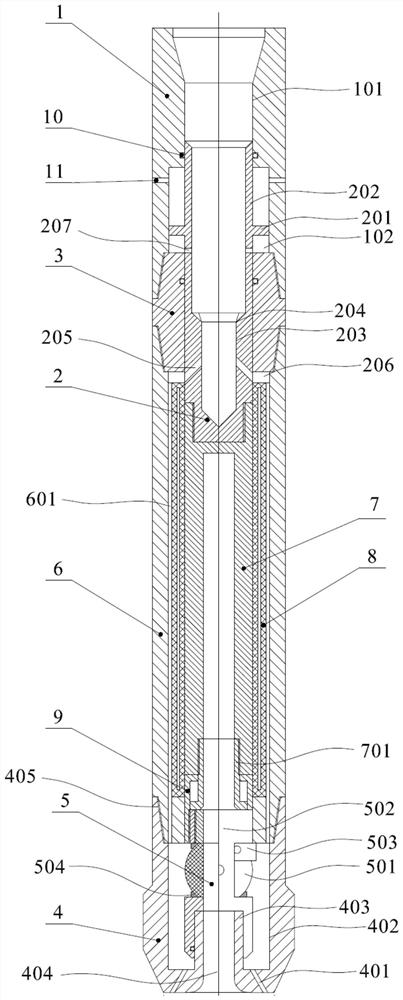

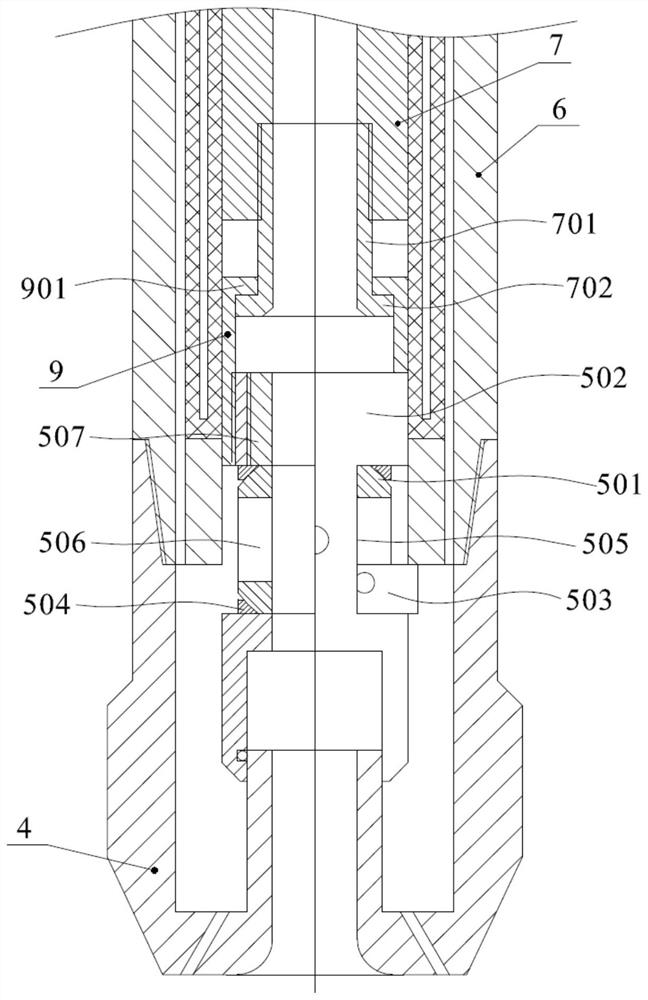

[0033] figure 1 It is a schematic diagram of the state of the coring device opening the ball valve, figure 2 It is a schematic diagram of the state of the coring device closing the ball valve, image 3 Yes figure 2 Enlarged view of one end of the coring bit of the middle coring device, see Figure 1-Figure 3 As shown, the coring device includes an upper connecting button 1 , an outer coring cylinder 6 and a coring drill 4 which are connected in sequence. The upper connection buckle 1 is used to connect the power device to provide drilling power. The upper buckle has an axially arranged inner hole 101 , the inner hole 101 of the upper buckle 1 , the inner hole of the outer core barrel 6 and the inner hole 402 of the core drill 4 . The first shaft hole is formed in communication. The core drill 4 is provided with a drill inner hole 402 , the bottom surface of the drill inner hole 402 is provided with a core hole 404 , and one end of the hole of the drill inner hole 402 is...

Embodiment 2

[0035] The difference between the coring device in embodiment 1 and the coring device in embodiment 2 lies in the lifting mechanism. see Figure 1-Figure 3 As shown, the lifting mechanism includes a convex ring 201 arranged on the outer wall of the differential lifting rod 2, a ring groove 102 is formed on the inner wall of the inner hole 101 of the buckle, and the outer diameter of the convex ring 201 is the same as that of the The diameters of the annular grooves 102 are equal. The convex ring 201 is arranged in the ring groove 102 , and the differential lift rod 2 is provided with a second communication hole 207 , and the second communication hole 207 is located on the convex ring 201 close to the core bit 4 On one side, the second communication hole 207 communicates with the inner hole 101 of the buckle, the side wall of the ring groove 102 is provided with a second drain hole 11, and the second drain hole 11 is located in the convex ring 201 is away from the side of the...

Embodiment 3

[0039] see Figure 1-Figure 3 As shown, on the basis of Embodiment 2, the inner wall of the outer coring cylinder 6 is provided with a vacuum thermal insulation sleeve 8, which further heats and insulates the inner coring cylinder 7. The upper connection buckle 1 and the outer core-taking cylinder 6 are connected by a connecting head 3 . Both ends of the connecting head 3 have a tapered structure, and two ends of the core-taking outer cylinder 6 are provided with tapered holes to be threadedly connected to the connecting head 3 . The connecting groove 206 is formed on the connecting head 3 and the outer coring cylinder 6 , or the connecting head 3 and the bottom surface of the taper hole of the outer core 6 are spaced to form the connecting groove 206 . The coring outer cylinder 6 and the coring bit 4 are threadedly connected. The chamfering of the mouth of the inner hole 402 of the drill bit forms a tapered hole structure 404, the two ends of the outer core-taking cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com