A device and method for controlling springback in plate forming

A sheet metal forming and equipment technology, which is applied in the field of forging processing, can solve the problems of large residual stress, springback, and easy springback phenomenon, and achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

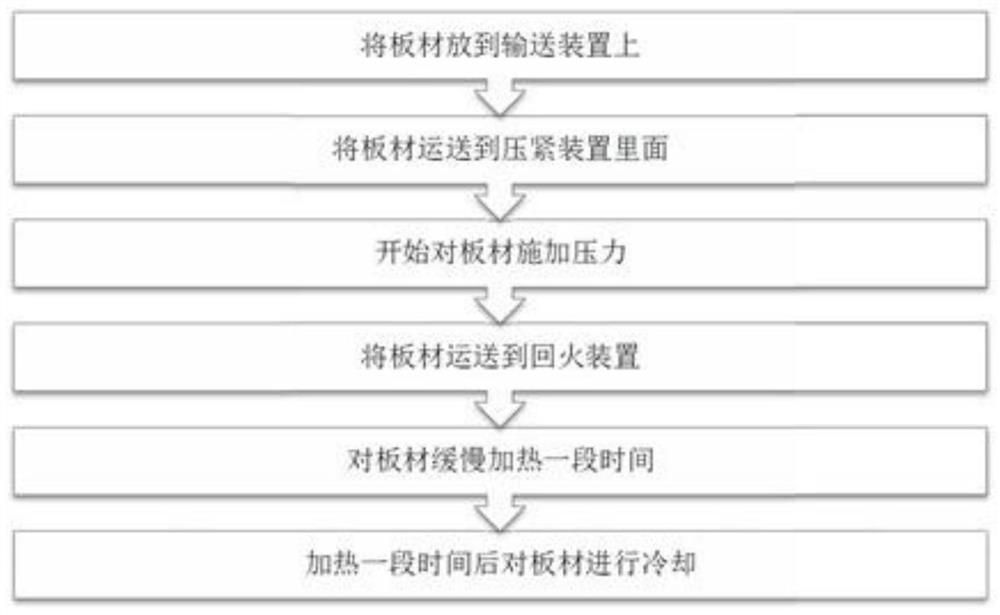

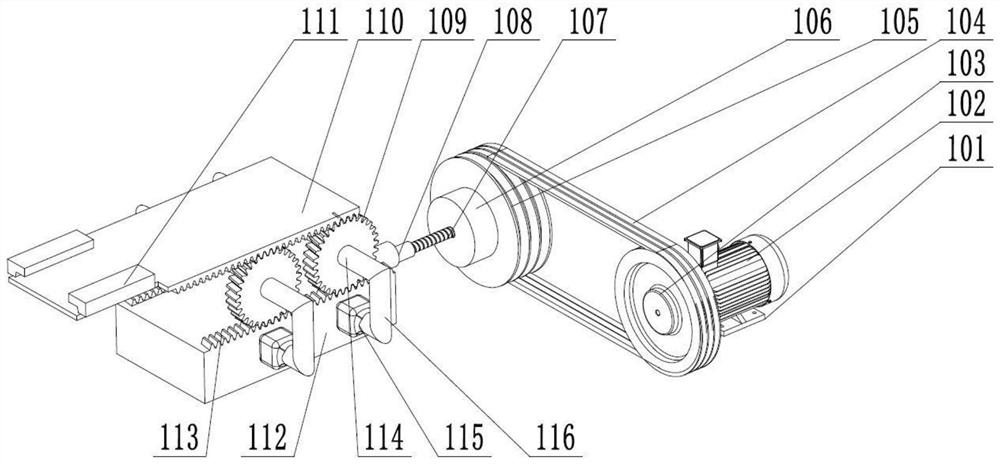

[0026] Example: such as figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 Shown is a device for controlling the springback of sheet metal forming. Including a conveying device 1, a compacting device 2, and a tempering device 3, the processing method includes the following steps: ① put the plate on the conveying device after processing; ② transport the plate to the compacting device through the conveying device; ③ when the plate enters Start to apply pressure to the plate when it reaches the inside of the pressing device; ④ transport the plate to the tempering device after a period of time; ⑤ slowly heat the plate for a period of time; ⑥ cool the plate after heating for a period of time.

[0027] Such as image 3 As shown, the power motor 102 is welded on the motor bracket 101, the driving wheel 103 is fixedly connected to the power motor 102, the belt 104 is slidably connected to the driving wheel 103, the driven wheel 105 is rotatably connected to the output rod 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com