Method for bending a glass sheet and apparatus therefor

A glass plate and bending technology, applied in glass manufacturing equipment, glass transportation equipment, glass forming, etc., can solve the problems of long time, shortened glass plate production time, impossible to increase productivity, etc., to prevent and improve the initial bending shape productivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Now, preferred embodiments of the method and apparatus for bending glass according to the present invention will be described in detail with reference to the accompanying drawings.

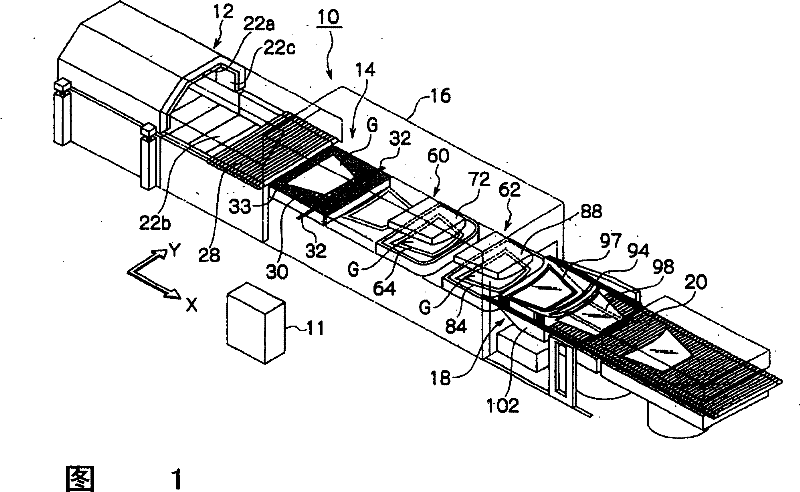

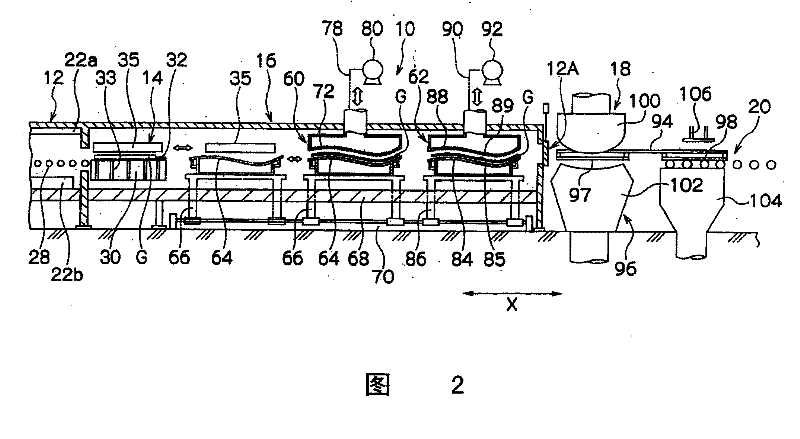

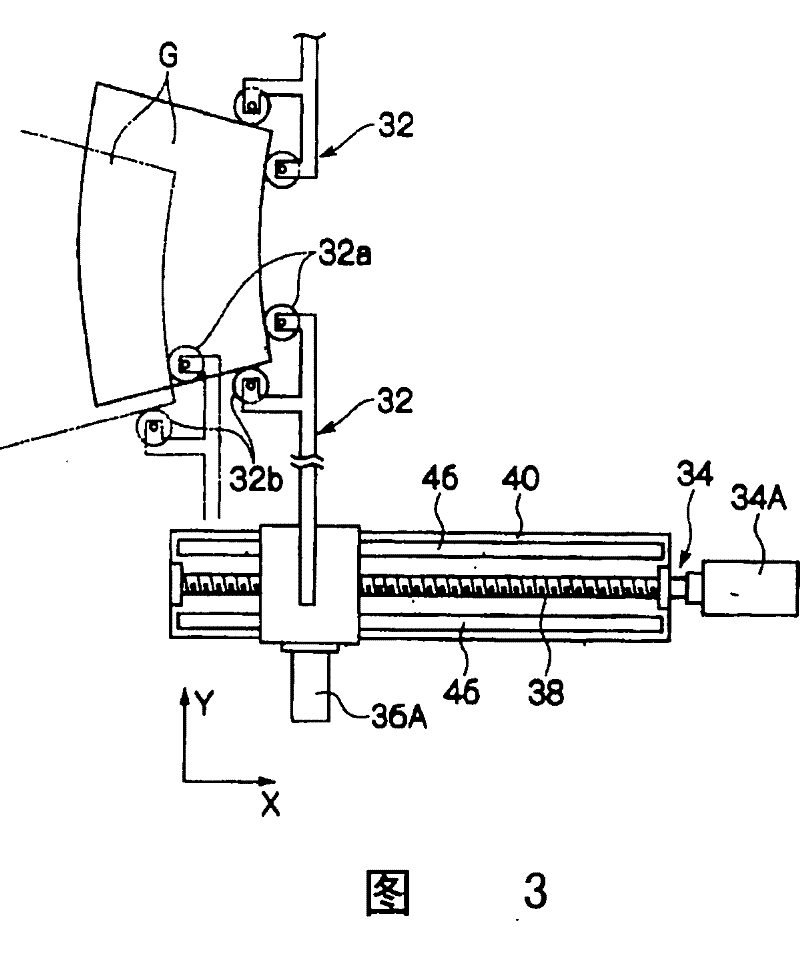

[0036] exist figure 1 and 2 shows an apparatus 10 for bending a glass sheet according to the first embodiment, which is configured to include a heating furnace 12, a positioning zone 14, a bending furnace in sequence from the upstream side to the downstream side in the direction of conveying the glass sheet G 16. Air cooling and tempering zone 18 and discharge roller conveyor 20. The controller 11 centrally controls the operation time, heater temperature, etc. in each process.

[0037] Furnace 12 is an electrically heated furnace and is divided into zones, (positioning zone 14 and bending furnace 16 are similar electrically heated furnaces). Each electrically heated furnace has a top heater 22a, a bottom heater 22b, and a side heater 22c. For some areas, heaters are not shown for simplici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com