Double elastic binder end stretching equipment

A technology of stretching equipment and material end, which is applied in the field of stretching equipment at the end of double elastic pressing material, can solve the problems of reduced material elongation, poor product dimensional stability, and large manpower and material resources, so as to reduce the degree of material hardening and optimize the exterior decoration The surface of the part and the effect of avoiding optical deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0022] Combine below Figure 1 to Figure 5 The technical solution provided by the present invention is described in more detail.

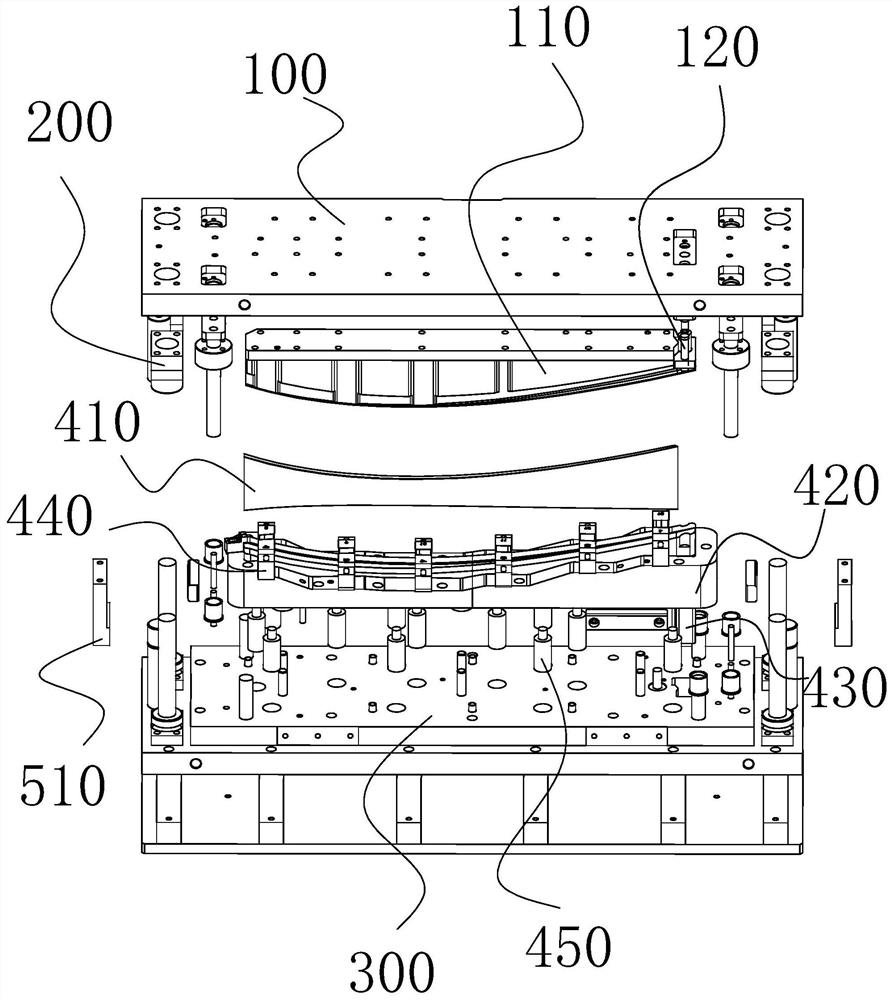

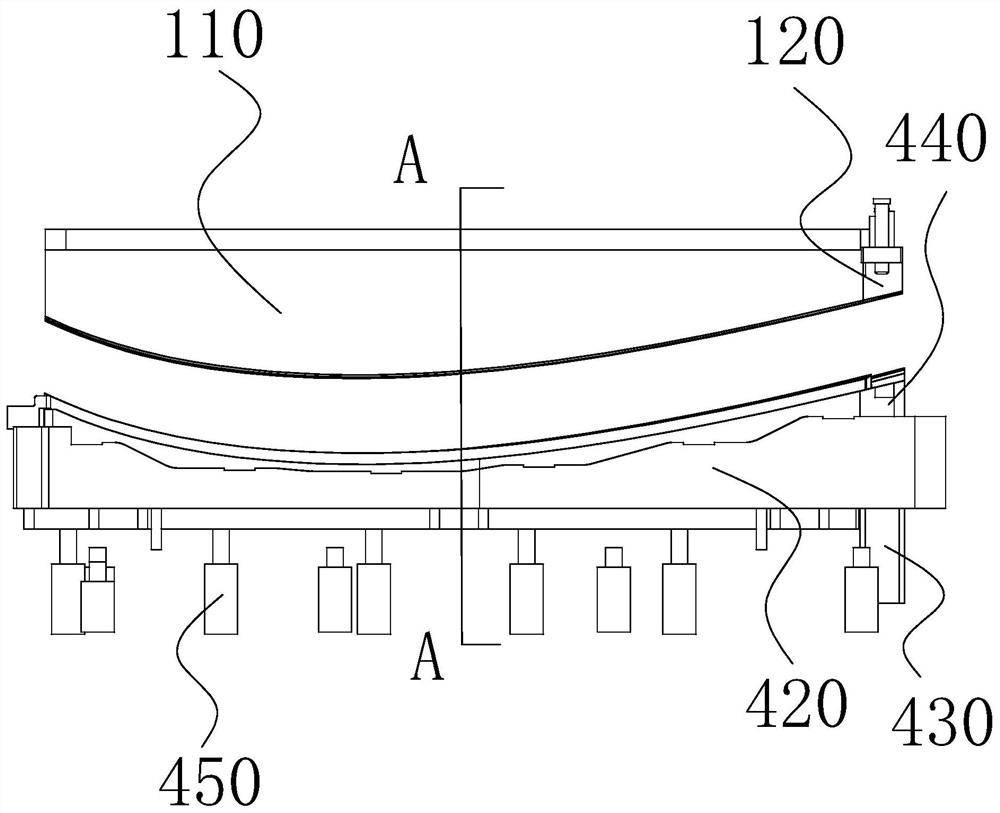

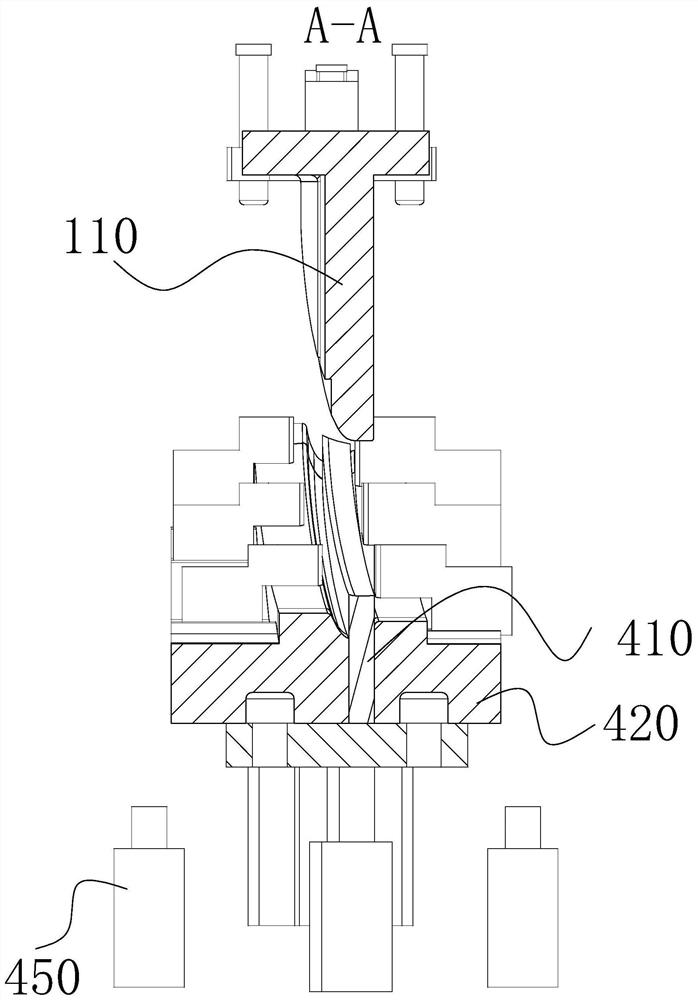

[0023] Such as Figure 1 to Figure 5 As shown, the double elastic binder end stretching equipment includes an upper fixed plate 100, a mold core 110, a lower elastic top block structure, and a mold base 300 arranged in sequence, and a guide rail is connected between the upper fixed plate 100 and the mold base 300. Column 200, the mold core 110 is installed on the end surface of the upper fixing plate facing the mold base, the lower ejection block structure is installed on the end surface of the mold base facing the upper fixing plate, and the lower ejection block structure includes at least T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com