Semi-penetrating and semi-reflecting liquid-crystal displaying panel, pixel structure and manufacture thereof

A semi-transmissive, semi-reflective, liquid crystal display panel technology, applied in semiconductor/solid-state device manufacturing, transistors, static indicators, etc., can solve the problems of increasing backlight, energy consumption, etc., to improve light reflectivity, increase brightness, Enhance the effect of the refraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

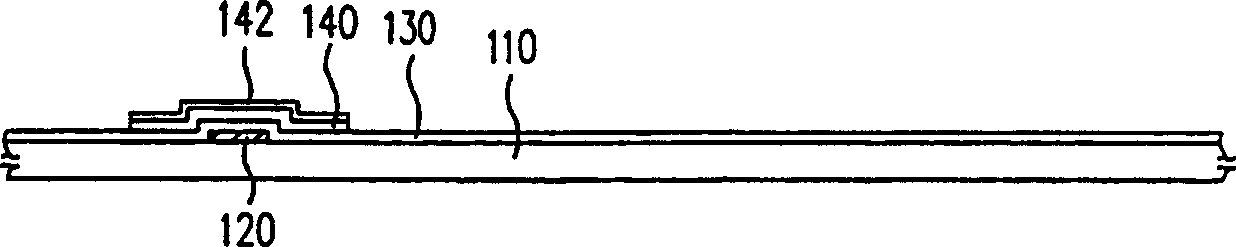

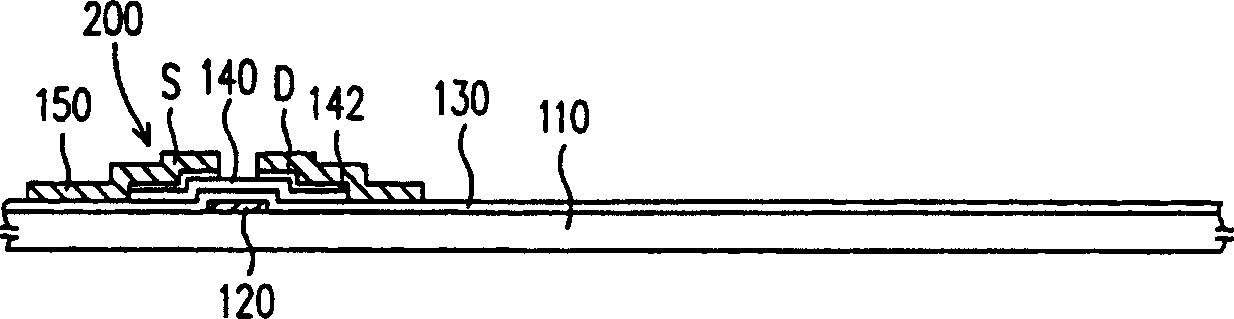

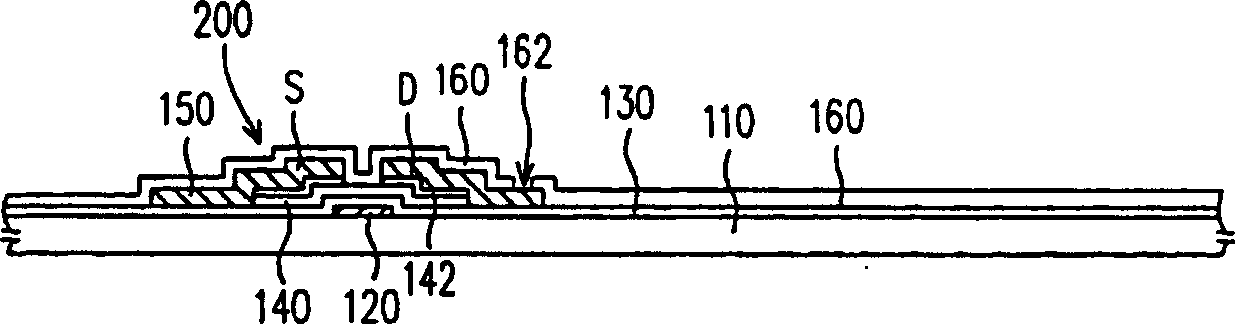

[0062] 1A-1F show the cross section of the manufacturing process of the transflective pixel structure according to the first embodiment of the present invention. figure 2 A schematic top view of the transflective pixel structure according to the first embodiment of the present invention is shown. Please refer to Figure 1A and figure 2 First, a scanning wiring 190 and a grid 120 are formed on a substrate 110, wherein the material of the substrate 110 is, for example, a glass substrate, a plastic substrate or other materials, and the material of the scanning wiring and the grid 120 is, for example, Chromium (Cr), tantalum (Ta) or other metal materials. After that, a gate insulating layer 130 is formed to cover the scan wiring 190 and the gate electrode 120 . Wherein, the material of the gate insulating layer 130 is, for example, silicon oxide, silicon nitride or other dielectric materials. Next, a channel layer 140 is formed to cover the gate insulating layer 130 , wherei...

no. 2 example

[0071] Figure 3A~Figure 3D A cross-sectional schematic diagram of the manufacturing process of the pixel structure according to the second embodiment of the present invention is shown. Since the manufacturing process of this embodiment is similar to that of the first embodiment, the reference numbers of this embodiment follow those of the first embodiment. Please refer to Figure 3A , first carry out the first embodiment Figure 1A to Figure 1B The process described above, and after the protective layer 160 is formed on the substrate 110, a plurality of raised patterns 164 (bumps) are formed on the protective layer 160 at the reflective area where the pixel electrode is scheduled to be formed, and the material thereof is, for example, organic resin (organicresin) or Is other organic materials (organic material). Wherein, the method of forming the protruding pattern 164 is, for example, firstly forming an organic material on the above-mentioned formed structure, and then pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com