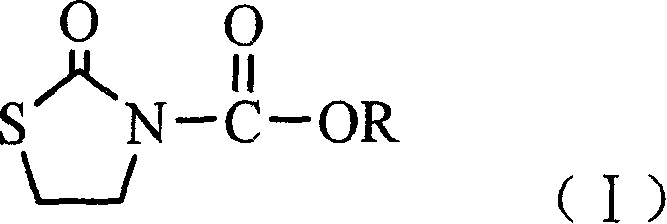

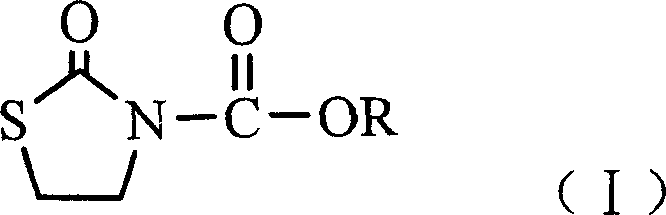

N-alkoxide oxo-2-triazolidone derivative, its preparation and use

A technology of thiazolidinone and alkoxycarbonyl, applied in the field of N-alkoxycarbonyl-2-thiazolidinone derivatives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

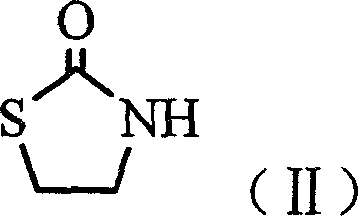

[0023] Example 1 Synthesis of N-pentyloxycarbonyl-2-thiazolidinone

[0024] Add 19.8g (0.067mol) of bis(trichloromethyl)carbonate and 50ml of dichloromethane into a 250ml three-necked flask, and slowly add n-amyl alcohol (0.2mol) under stirring. Under cooling in an ice bath, a solution of triethylamine (0.2 mol) and 10 ml of dichloromethane was slowly added dropwise, maintaining the temperature between 0 and 5°C. After the dropwise addition was completed, the temperature was raised slowly and stirred at 20° C. for 2 hours. Wash with water three times (3×50ml), dry over anhydrous sodium sulfate, filter, concentrate, and distill out n-pentyl chloroformate under reduced pressure. Yield 85.6%.

[0025] 2-Thiazolidinone (5mmol) and triethylamine (0.72g, 7mmol) were dissolved in 10ml of dichloromethane and stirred. Under cooling in an ice bath, the above n-amyl chloroformate (6 mmol) was added dropwise. After the dropwise addition was completed, the reaction was carried out at 0...

Embodiment 2

[0033] Example 2 Synthesis of N-isoamyloxycarbonyl-2-thiazolidinone

[0034] Add 19.8 g (0.067 mol) of bis(trichloromethyl) carbonate and 50 ml of chloroform into a 250 ml three-neck flask, and slowly add isoamyl alcohol (0.2 mol) while stirring. Under cooling in an ice bath, a solution of pyridine (0.2 mol) and 10 ml of chloroform was slowly added dropwise, maintaining the temperature between 0 and 5°C. After the dropwise addition was completed, the temperature was raised slowly and stirred at 25° C. for 2 hours. Wash with water three times (3×50ml), dry over anhydrous sodium sulfate, filter, concentrate, and evaporate isoamyl chloroformate under reduced pressure. Yield 82.7%.

[0035] 2-Thiazolidinone (5mmol) and triethylamine (0.82g, 8mmol) were dissolved in 15ml of dichloromethane and stirred. Under cooling in an ice bath, the above-mentioned isoamyl chloroformate (6 mmol) was added dropwise. After the dropwise addition was completed, the reaction was carried out at 0-...

Embodiment 3

[0043] Example 3 Synthesis of N-butoxycarbonyl-2-thiazolidinone

[0044] N-pentanol is replaced by n-butanol, and others are the same as in Example 1 to obtain n-butyl chloroformate. Yield 88.3%.

[0045] 2-Thiazolidinone (5mmol) and pyridine (0.56g, 7mmol) were dissolved in 10ml of chloroform and stirred. Under cooling in an ice bath, the above n-butyl chloroformate (6 mmol) was added dropwise. After the dropwise addition was completed, the reaction was carried out at 0-10°C for 9 hours. Washed three times with water, dried over anhydrous sodium sulfate, filtered and concentrated. The residue was separated and purified by column chromatography [V (petroleum ether): V (ethyl acetate) = 3: 1] to obtain 0.77 g of light yellow transparent oily N-n-butoxycarbonyl-2-thiazolidinone (compound No. 6 ). The yield was 76.3%.

[0046] Elemental Analysis Values:

[0047] C H N

[0048] Measured value (%): 47.43 6.69 6.85

[0049] Calculated value (%): 47.27 6.44 6.89

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com