Method for manufacturing air bridge by composite glue electric-plating

A composite glue and air bridge technology, which is applied to electrical components, chemical/electrolytic methods to remove conductive materials, circuits, etc., can solve problems such as corrosion, incompleteness, wrinkling and peeling of plating layers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

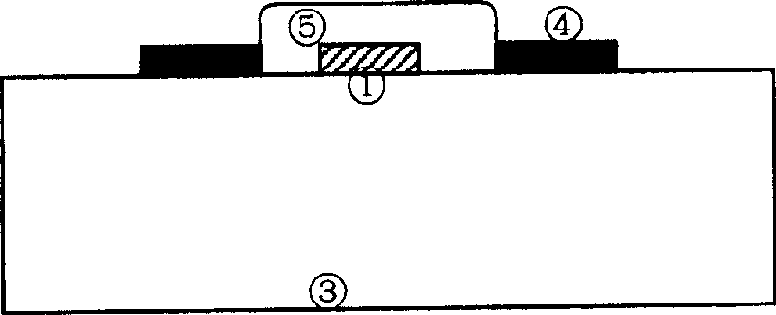

[0042] Step 1, coating compound glue 6 on the substrate 3

[0043] First apply PMMA (Polymethylmethacrylate) glue, and then 9918 glue, of which PMMA (Polymethylmethacrylate) is about 1000 , because PMMA (Polymethylmethacrylate) is high temperature Glue can avoid the problems of glue cracking, denaturation, and dryness caused by high temperature in the whole production process. The use of this composite glue 6 successfully solves the wrinkling of the coating 7 ( Figure 19 ) problem, and played a very important role in the complete stripping of the coating 7, obviously, using the stripping effect of the composite glue 6 ( Figure 21 ) is better than using a single layer of glue 5 ( Figure 20 ) is much better. The thickness of the 9918 glue depends on the height of the arch of the air bridge 2. If the glue is relatively thick, it needs to be glued twice, and the hardening time should be prolonged appropriately.

[0044] Step 2. Bake at high temperature to make the edges and...

Embodiment 2

[0058] Step 1, coating compound glue 6 on the substrate 3

[0059]First apply PMMA (Polymethylmethacrylate) glue, and then 9918 glue, of which PMMA (Polymethylmethacrylate) is about 1000 , because PMMA (Polymethylmethacrylate) is high temperature Glue can avoid the problems of glue cracking, denaturation, and dryness caused by high temperature in the whole production process. The use of this composite glue 6 successfully solves the wrinkling of the coating 7 ( Figure 19 ) problem, and played a very important role in the complete stripping of the coating 7. Obviously, the stripping effect of using the composite glue ⑥ ( Figure 21 ) is better than using a single layer of glue 5 ( Figure 20 ) is much better. The thickness of the 9918 glue depends on the height of the arch of the air bridge 2. If the glue is relatively thick, it needs to be glued twice, and the hardening time should be prolonged appropriately.

[0060] Step 2. Bake at high temperature to make the edges and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com