Sterilizing reagent kit for washing machine and its sterilizing method

A technology for a kit and a washing machine, which is applied to the control device of a washing machine, other washing machines, applications, etc., can solve the problem that the volume of the sterilizing water generating mechanism 22 has not been improved, and achieve novel and simple structure, increased service life, and good integrity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

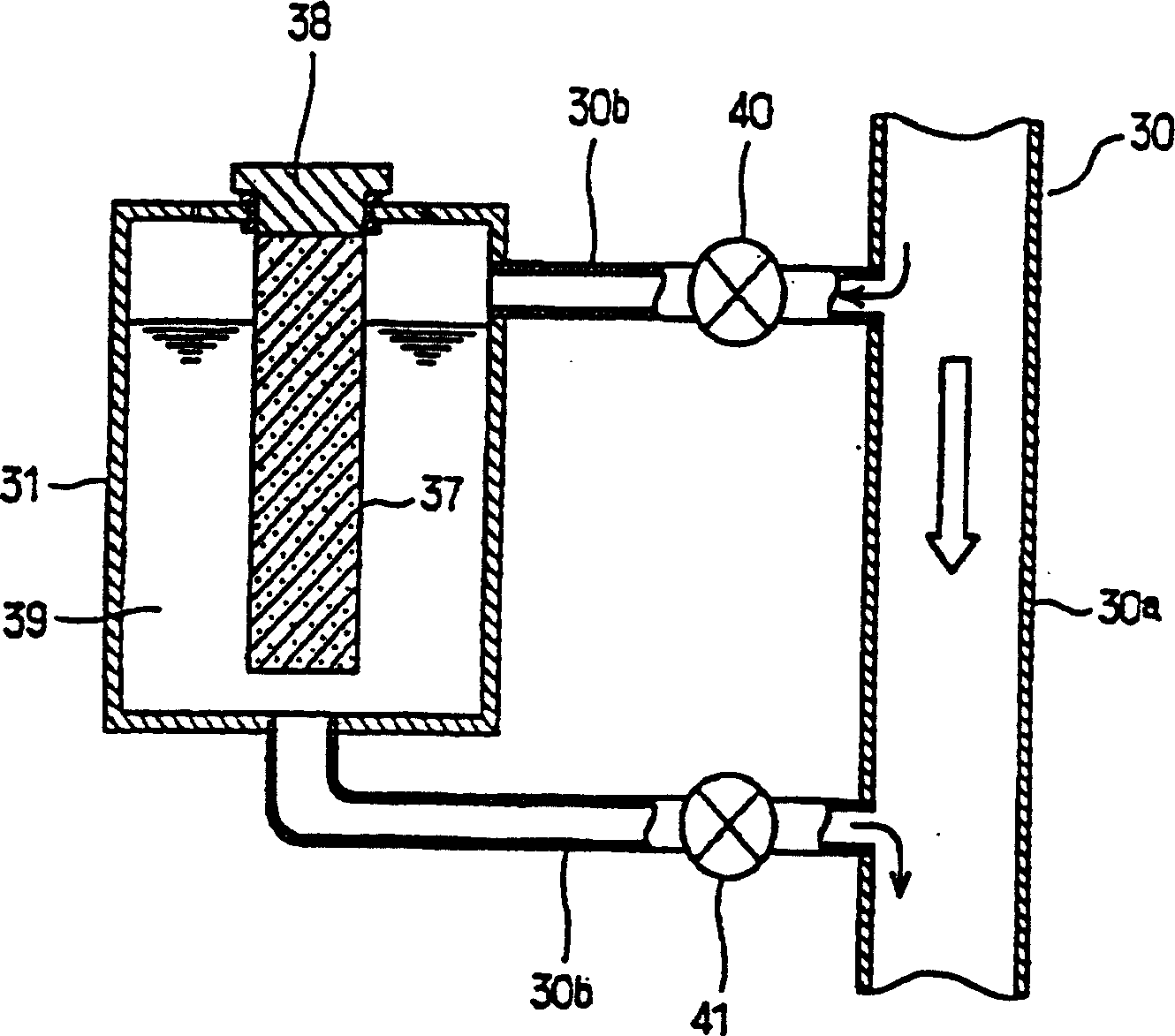

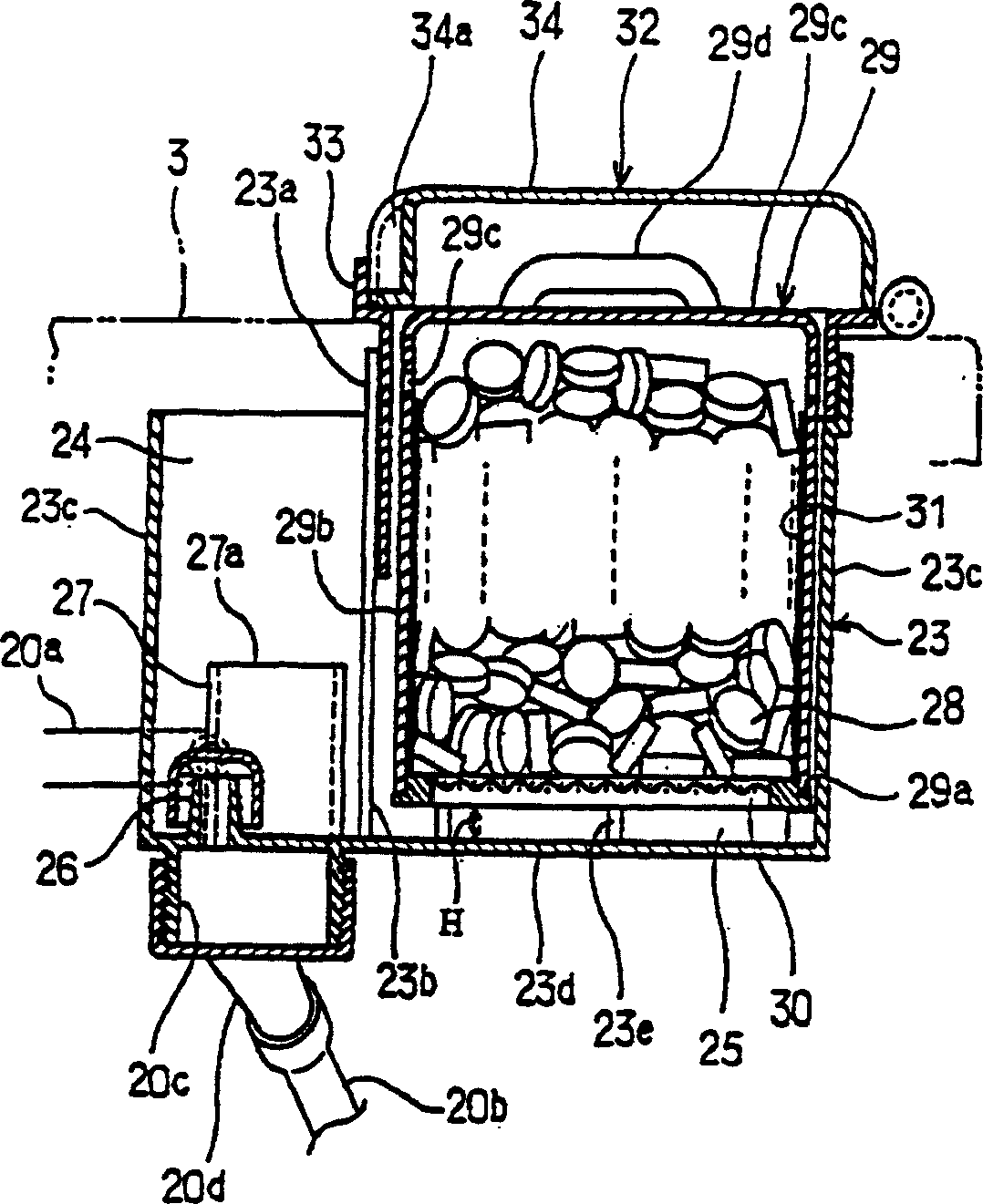

[0036] Such as Figure 4 , is a cross-sectional view of an embodiment of the disinfection kit of the present invention, the disinfection kit includes: an outer box 1, an inner box 2, a water outlet 3 arranged at the bottom of the outer box 1, a water injection pipe 4 connected to a water inlet valve at one end, and a water outlet 3 Directly leading to the washing bucket, the inner box 2 is overhead and fixed in the outer box 1, and an overflow hole 21 is set on one side of the inner box 2, and the bottom of the inner box 2 is provided with a siphon for both water inlet and outlet channels Device 5, the other end of water injection pipe 4 passes through outer box 1, inner box 2 and stretches in the siphon device 5, has drainage pipe 41 on water injection pipe 4.

[0037] It can be seen from the figure that the siphon device 5 includes a siphon pipe 51 and a part of the water injection pipe 52 extending into the siphon pipe 51 . The water injection pipe 4 is in the shape of a "...

Embodiment 2

[0047] Such as Figure 5 , is a cross-sectional view of another embodiment of the disinfection kit of the present invention, its overall structure is roughly the same as that of the disinfection kit shown in Embodiment 1, the difference is that a water inlet is provided on the water inlet of the water injection pipe 4 Control valve 7, so that it is slightly different in method. When the water inlet level does not need to reach the equilibrium water level H, close the water inlet control valve 7, and then use the siphon phenomenon to pass through the siphon pipe 51 and part of the water injection pipe 52. The sterilizing solution in 2 is sucked out, and is discharged in the washing bucket through drainpipe 41, drain outlet 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com