Continuously variable transmission metal belt, process for producing metal ring, and process for measuring shape of metal ring

By forming a protrusion on the side edge of the metal ring and grinding it, combined with the lubrication effect of the laminated structure, the problem of short fatigue life of the metal ring side edge of the continuously variable transmission is solved, and higher durability and centering functions are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, an embodiment of the present invention will be described based on the drawings attached to the embodiments of the present invention.

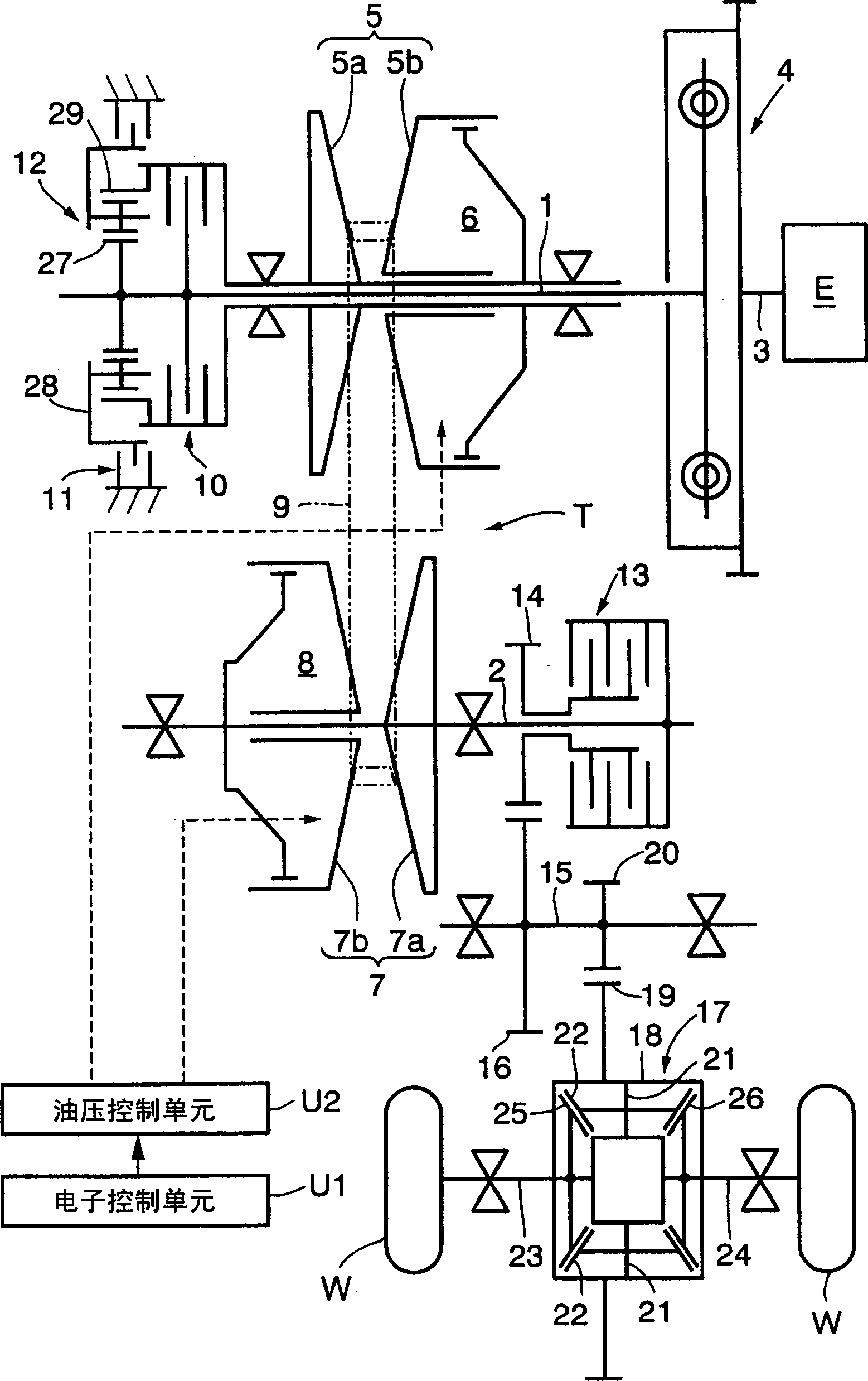

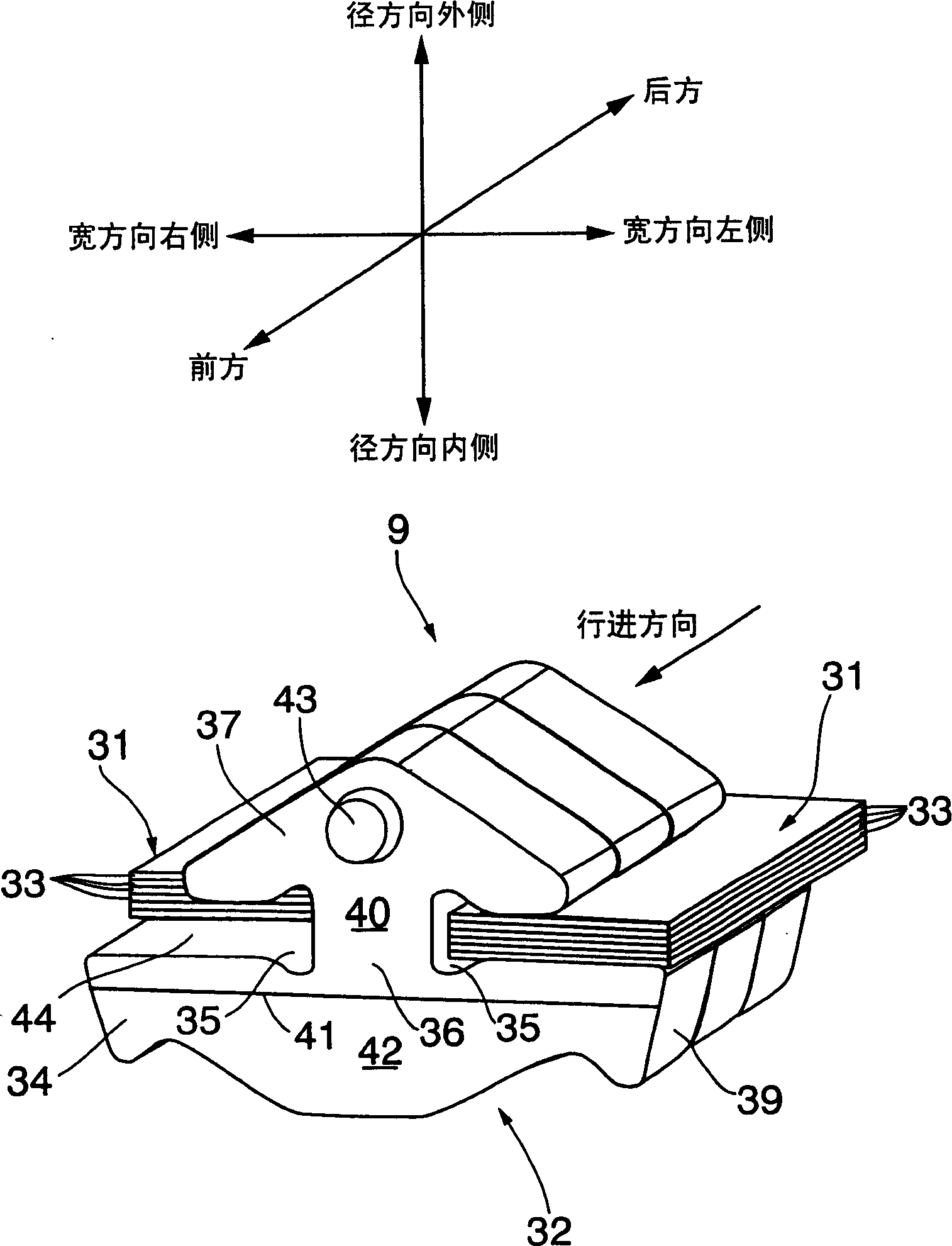

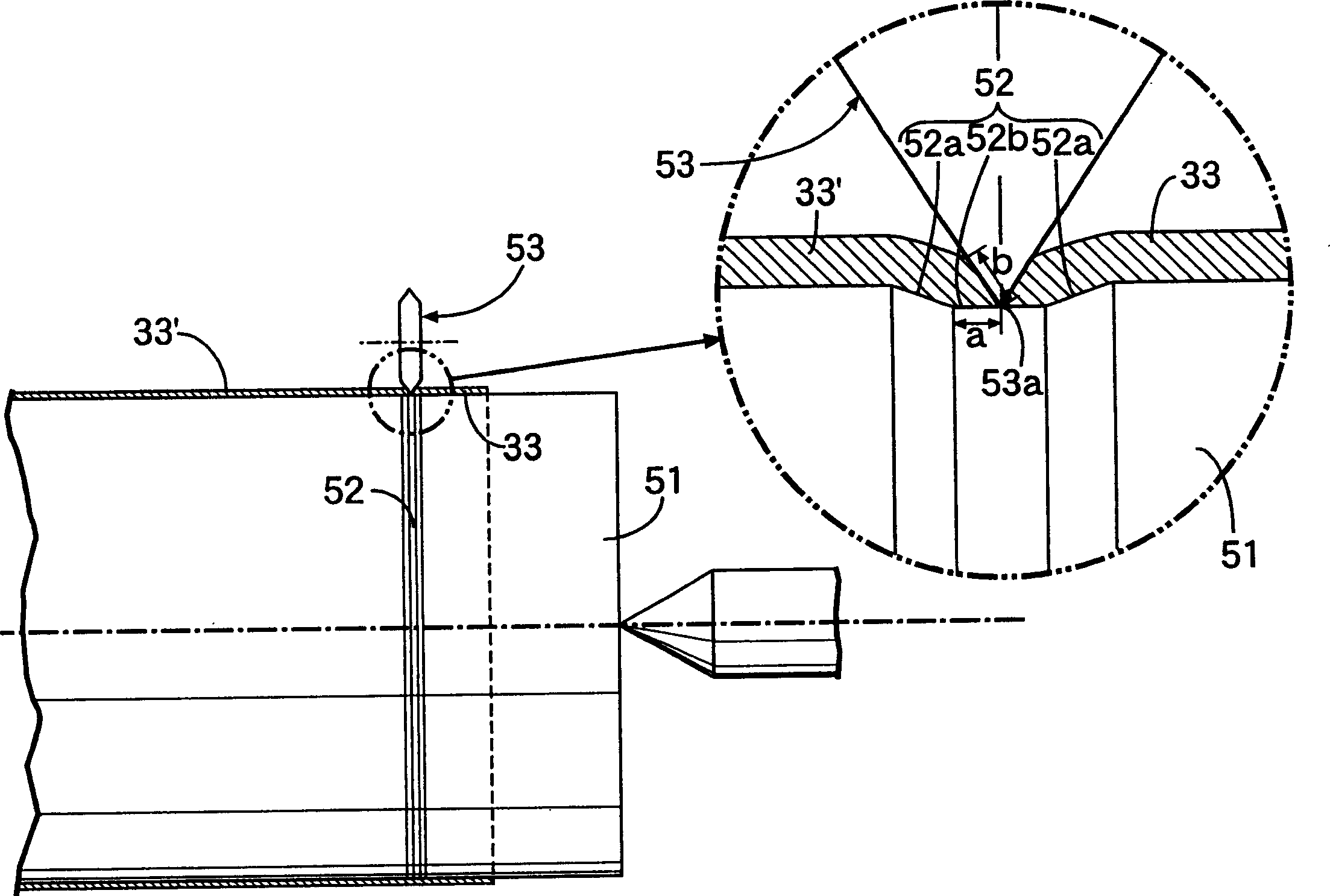

[0023] Figure 1 to Figure 8 is a diagram showing an embodiment of the present invention, figure 1 It is a schematic diagram of the power transmission system of a vehicle equipped with a metal belt continuously variable transmission, figure 2 is a partial perspective view of the metal ring, image 3 It is an explanatory diagram of the spinning process of the metal ring, Figure 4 It is a figure showing a cut metal ring and a ground metal ring, Figure 5 It is a figure which shows the state in which the metal ring of an Example and a comparative example contact the V-shaped surface of a pulley, Figure 6 is a graph showing the stress acting on the metal ring in Examples and Comparative Examples, Figure 7 is an enlarged view of the end of the metal ring assembly, Figure 8 It is explanatory drawing of the method of mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com