Resilient brace

A braced, elastic technology used in the direction of springs, springs/shock absorbers, elongated structural members for load bearing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

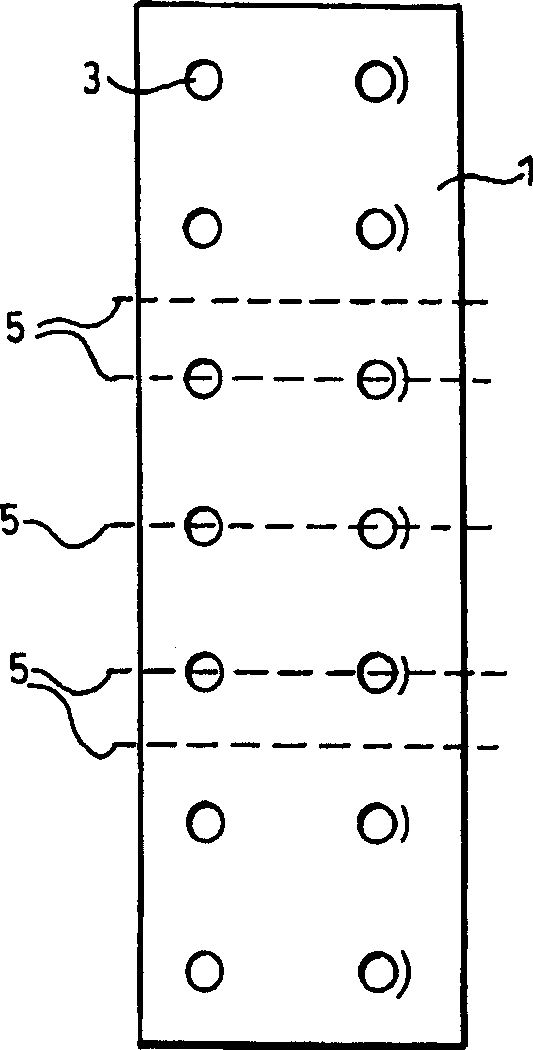

[0024] figure 1 A planar elongated die-cut sheet 1 of spring steel from which an elastic brace according to an embodiment of the invention can be produced is shown. Die-cut sheet material 1 is arranged with many holes 3 in two rows equidistant along its central long axis, and the holes 3 in each row are equidistant from each other and distributed in pairs along the transverse direction. The elastic brace according to the embodiment of the present invention can be made by bending the die-cut sheet material 1 along the fold line 5 in exchange directions. Fold line 5 passes in the middle of two pairs of holes 3 except that the outermost two are equidistant, and all the others pass through each pair of holes 3 . The arrangement of the folding lines directly affects the working mode of the elastic braces, which will be described in detail below with reference to FIG. 2 .

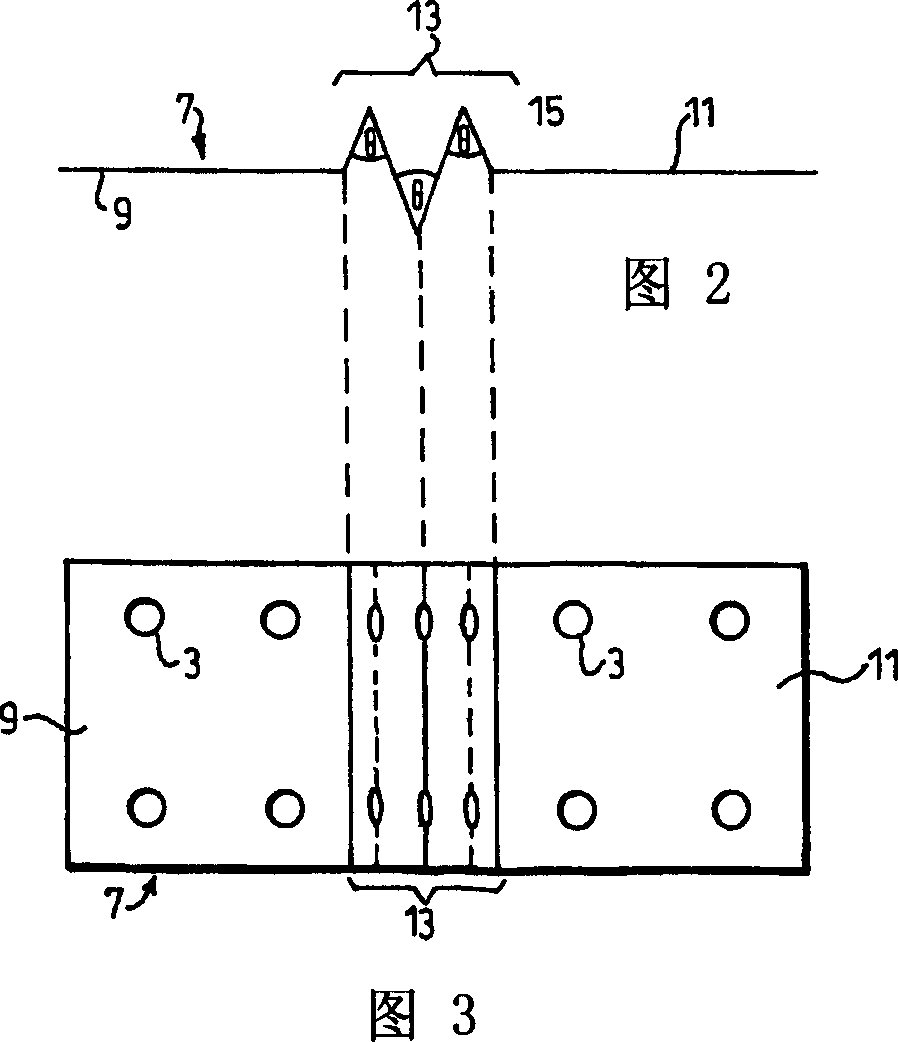

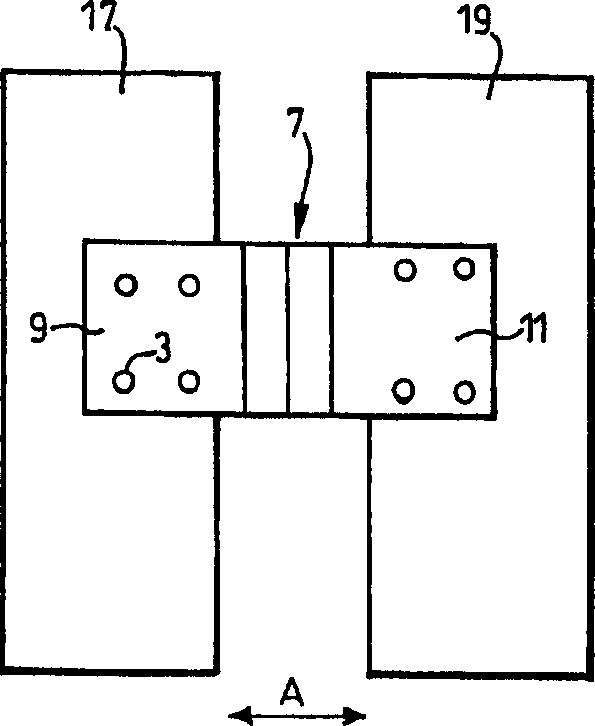

[0025] Figure 2 shows the figure 1 Elastic braces made of die-cut sheets. The first and second planar conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com