Post-construction anchor, and drill bit for drilling prepared holes therefor

A threaded bottom hole and post-construction technology, used in stone processing equipment, stone processing tools, metal processing equipment, etc., can solve the problems of pulling out the fixture and the state of insufficient close contact again, and achieve excellent pulling endurance, Excellent workability and usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

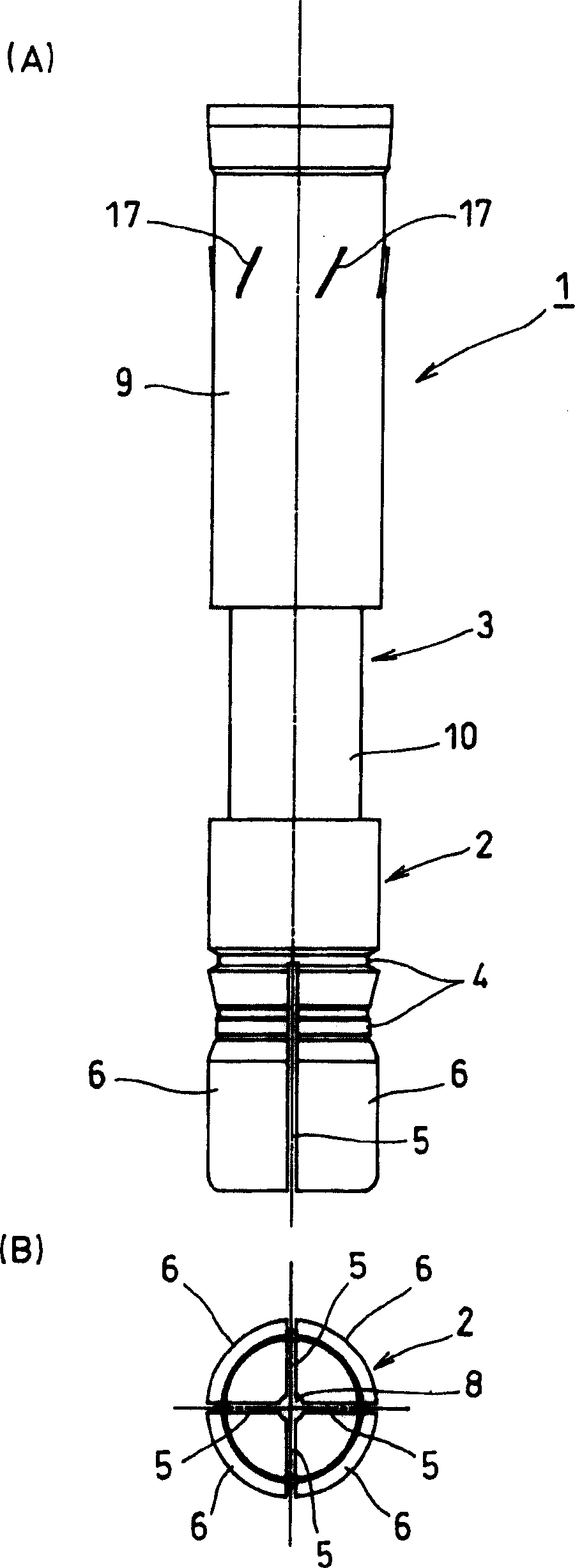

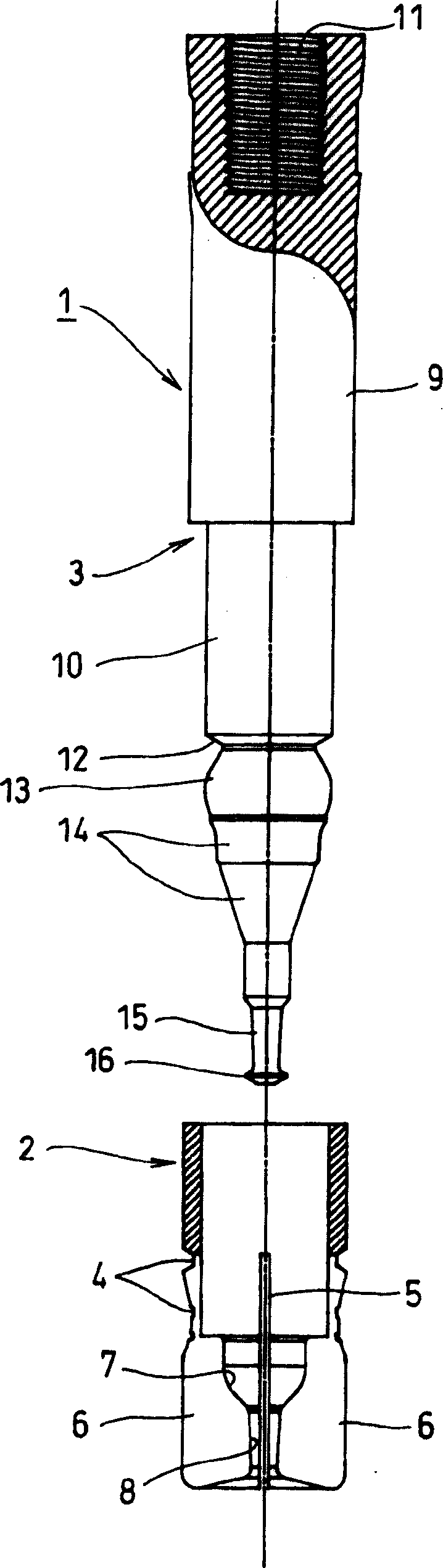

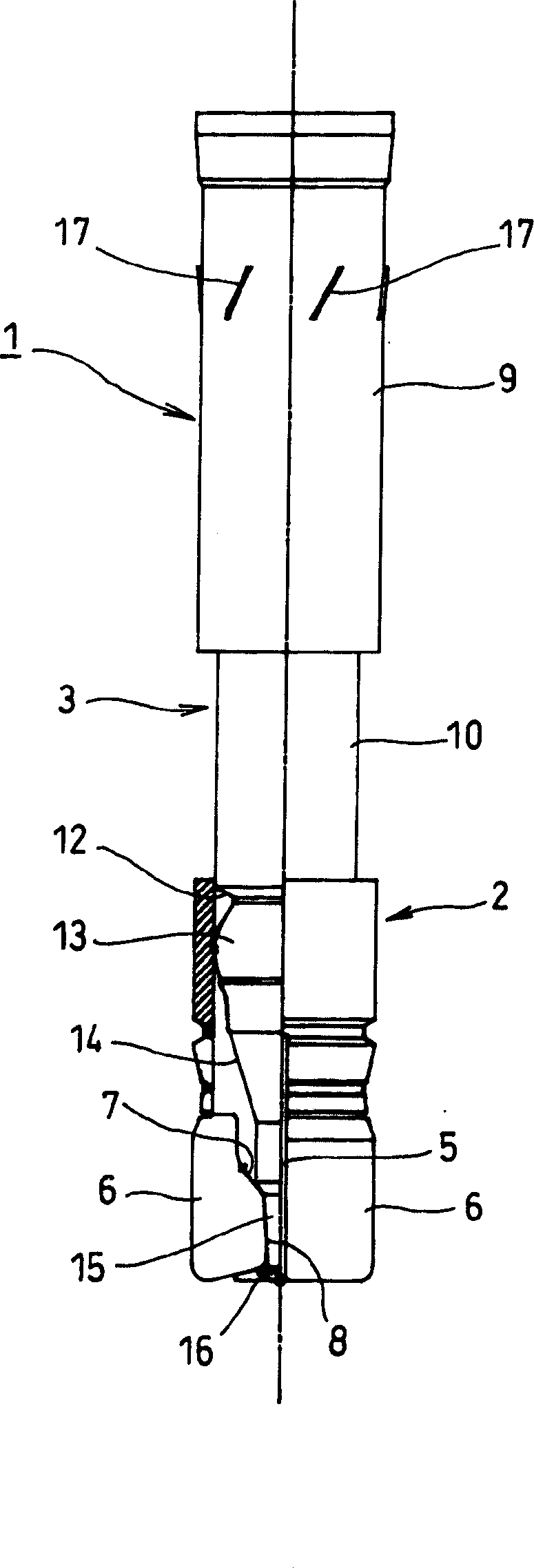

[0082] Figure 1-4 It is a diagram showing a preferred first embodiment of the post-construction anchor (hereinafter referred to as the anchor) related to the present invention, especially figure 1 (A) and (B) respectively represent the front view and bottom view of the fixture, figure 2 is to represent its disassembled anatomical view, and again, image 3 yes means figure 1 Half-section view of (A), Figure 4 It is a cross-sectional view showing the state before expansion and the state after expansion of the composite sleeve. In addition, this first embodiment corresponds to the invention described in claims 1-7.

[0083] Such as figure 1 , 2 As shown, the holder 1 is formed by a hollow cylindrical sleeve 2 and a substantially stepped shaft-shaped plug 3 pressed into the sleeve 2 as an expansion element.

[0084] On the outer peripheral surface of the sleeve 2, in addition to forming a plurality of peripheral grooves 4, the lower half of the sleeve 2 is cut into a col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com